Method for the fermentation of ensilaged renewable raw materials

A technology of silage and raw materials, applied in the field of renewable raw materials, can solve the problems of biogas performance fluctuations, long reaction time, etc., and achieve the effects of improving performance quality, reducing investment costs, and shortening method time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

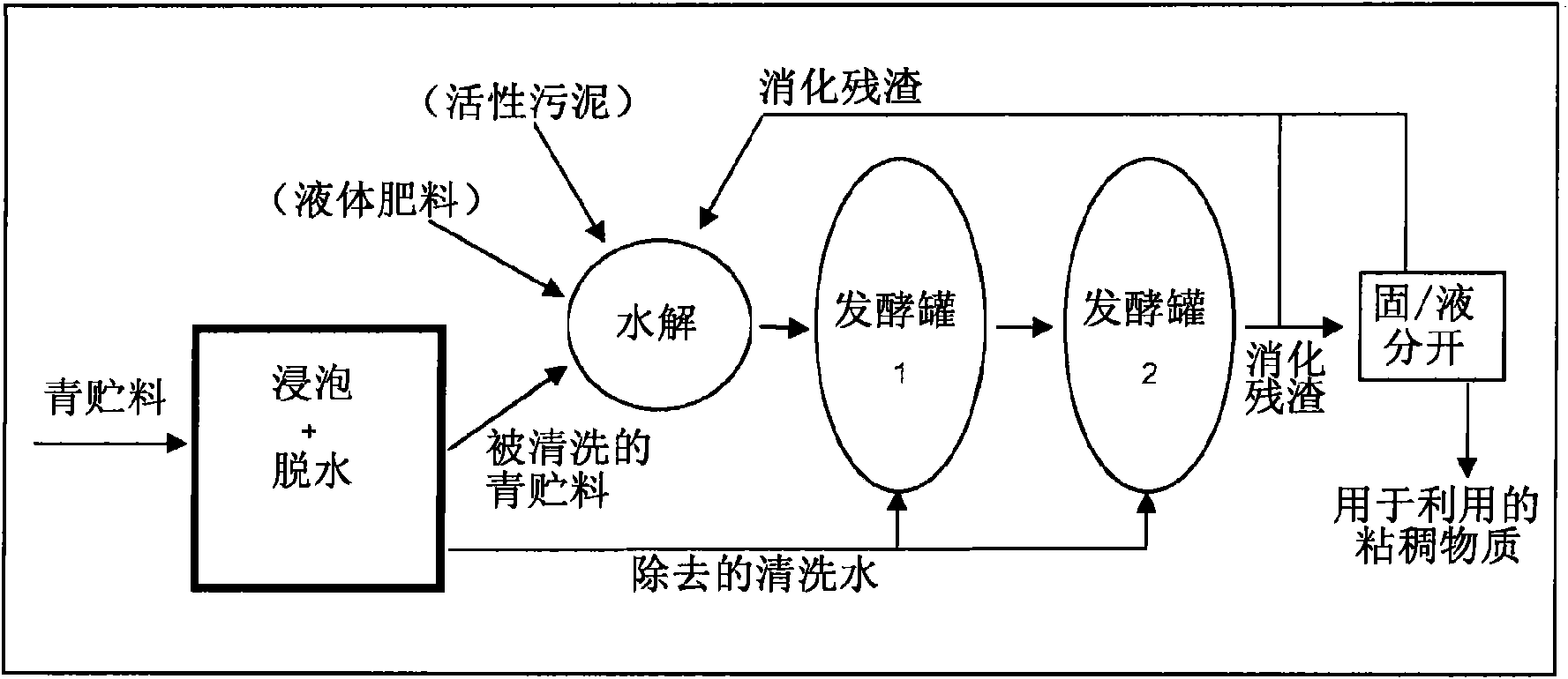

[0050] 1000 kg of silage consisting of 60% corn and 40% rye whole plant silage (Roggen GPS) was fed into the purge reactor. Subsequently, 1000 liters of liquid consisting of industrial water (effluent from the sewage treatment plant) were added to the cleaning reactor. After filling with the liquid, the silage was set in motion for 10 minutes by means of a kneading ram. The washed silage was then allowed to dwell in the washing reactor for 5 minutes at which time 100% of the washing water was removed from the silage by squeezing the silage. Catch the rinse water that is squeezed out. It had a composition of 2.5% dry matter content and 50 g / l dissolved CSB, and it was added to the fermenter present in the subsequent process stage. The silage that will be washed and partially dehydrated is sent in the hydrolysis reactor, and the liquid fertilizer of 0 mass %, the activated sludge of the resident sewage treatment equipment of 15 mass % and the 50 mass % of the activated sludge ...

Embodiment 2

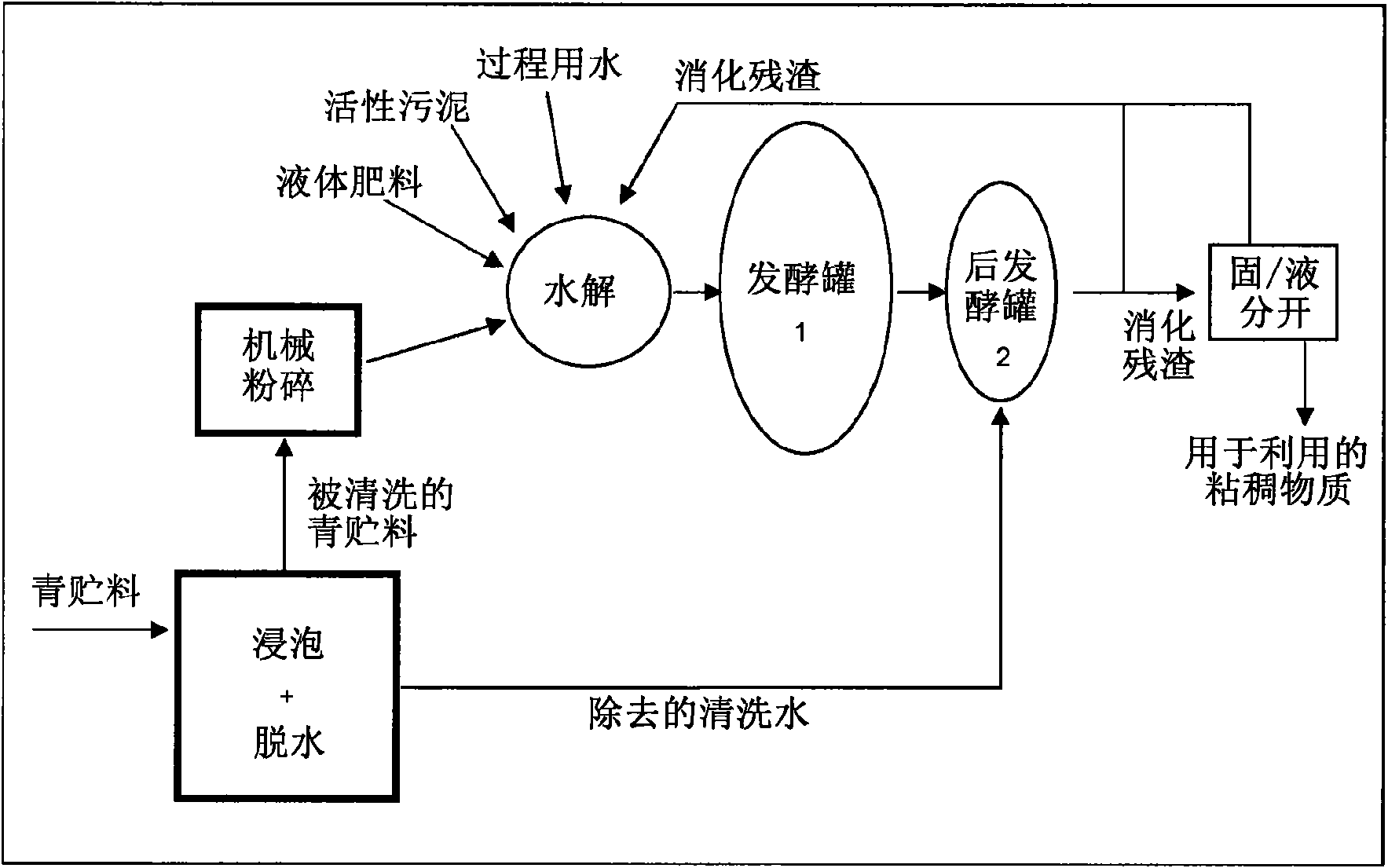

[0053] 1000 kg of silage consisting of 60% corn and 40% rye whole plant silage was fed into the purge reactor. Subsequently, 500 liters of liquid consisting of industrial water (effluent from the sewage treatment plant) were added to the cleaning reactor. The washed silage is then left in the washing reactor for 5 minutes, whereby the washing water permeates through the silage body due to gravity and collects at the bottom. The hydrated silage was remixed by emptying the entire container without further mechanical thorough agitation. The silage-water-mixture is fed via a conveying device to a screw press where the washing water is squeezed out. The dehydration resulted in about 800 liters of squeezed water having a dry matter content of 4.5% and 55 g / l of dissolved CSB. The squeezed water is all sent to the post-fermenter of the two-stage series device. The washed and partially dewatered silage was comminuted continuously by means of a planetary roller extruder, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com