Water wand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

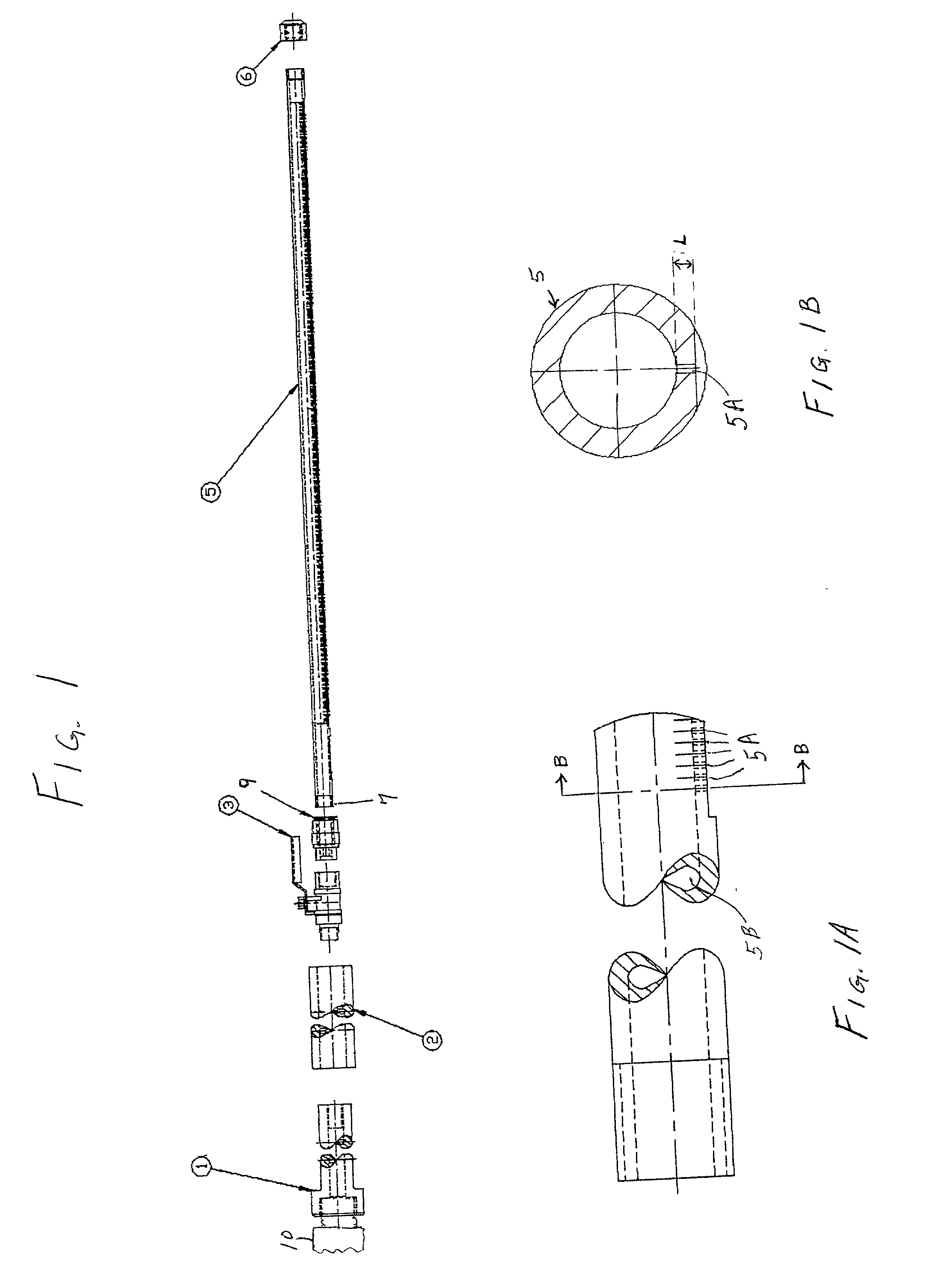

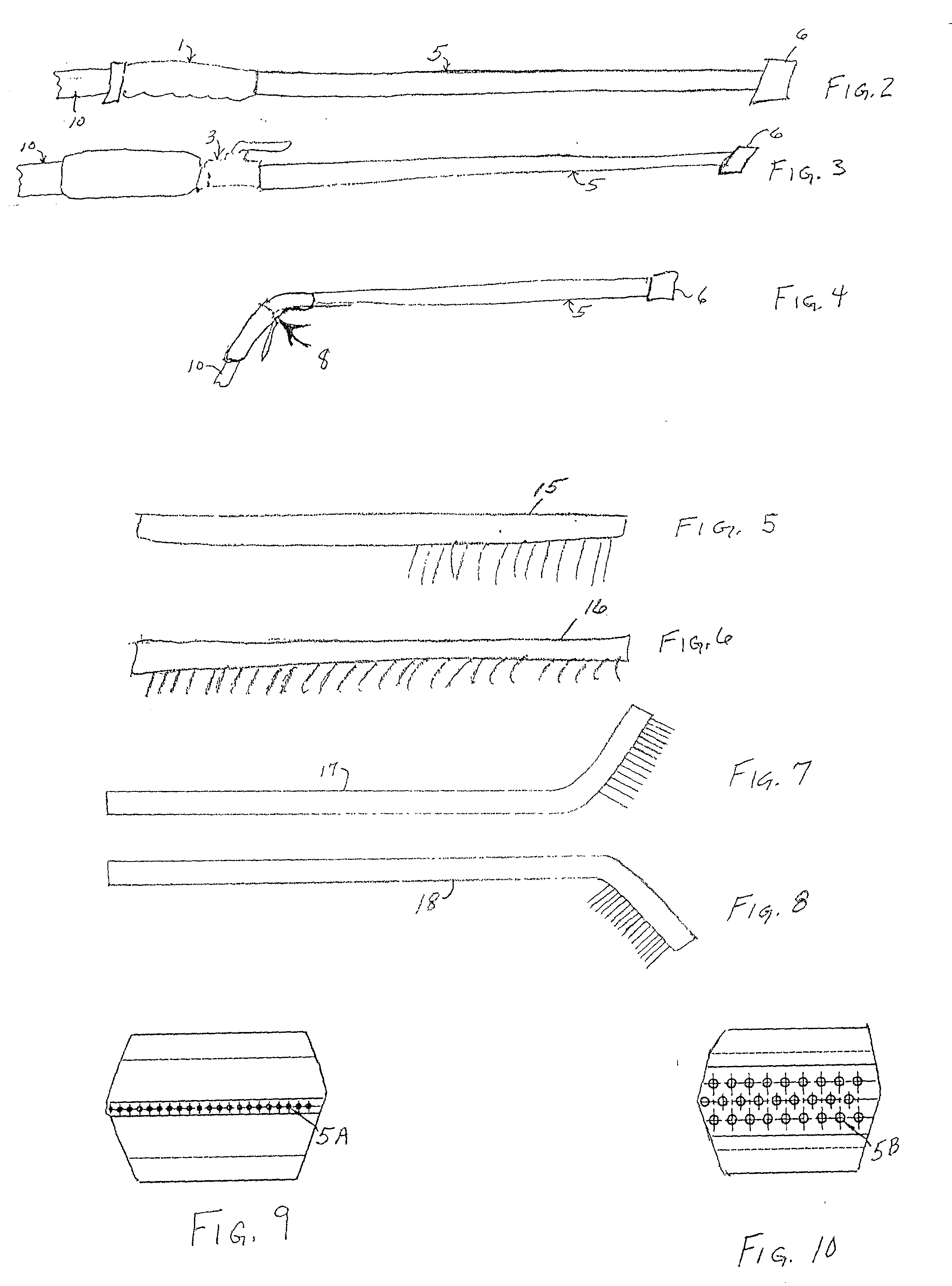

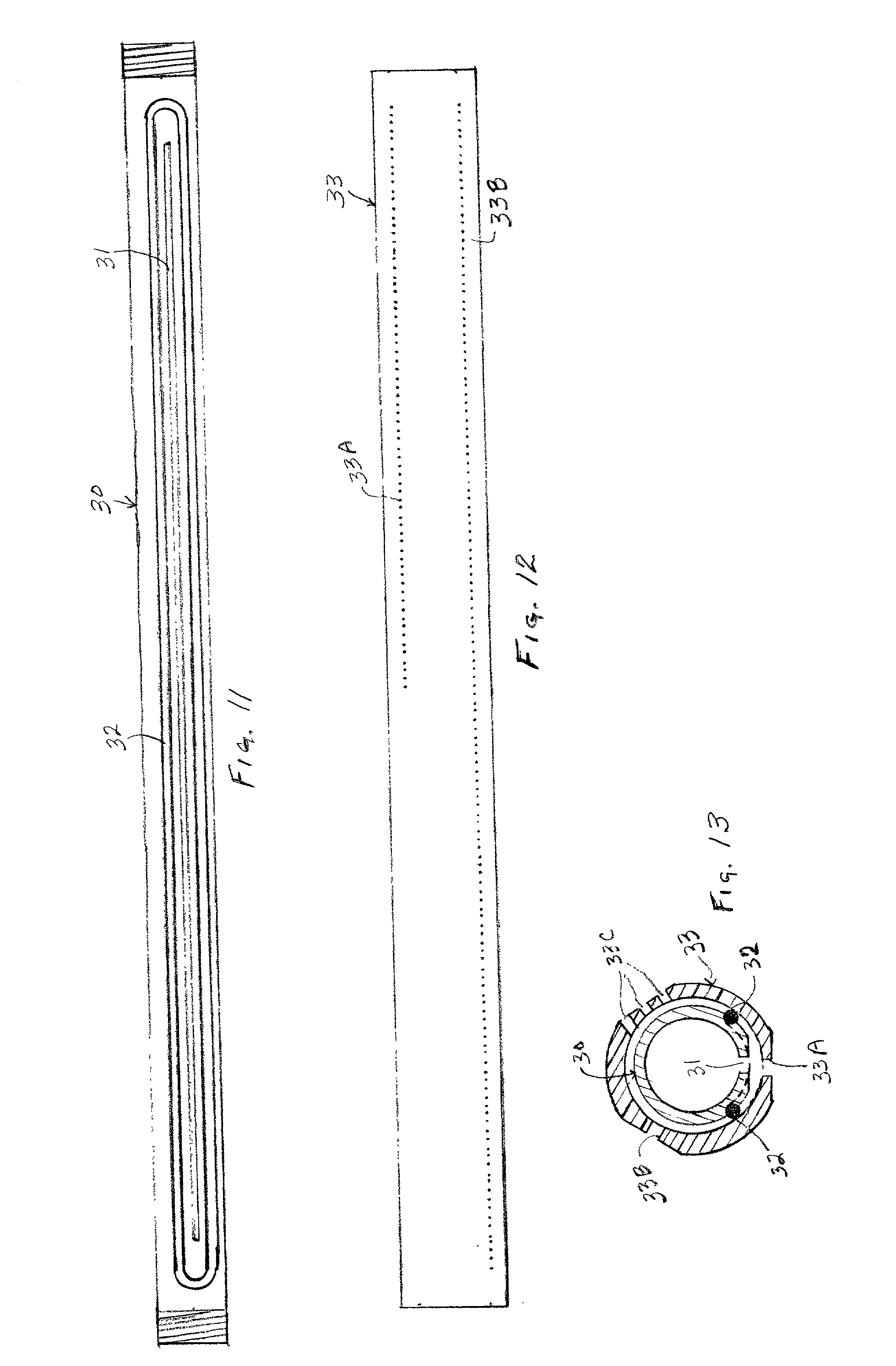

[0023] In FIGS. 1 and 1A there is shown one embodiment of a watering wand which includes an elongated tubular body 5 having an open end 7 and an opposite end which is closed by means of removable cap 6. The tubular body includes a plurality of openings 5A extending through a side wall of the tubular body so as to communicate with the interior passageway 5B of the tubular body. By having the removable cap 6 on the outer end of the wand, general maintenance of the wand is greatly facilitated. Dirt and debris can get into hoses which can clog the holes of the wand. By simply removing the cap 6, any dirt or debris can be flushed out through the outer end of the wand. When holes are clogged in any watering apparatus, water is deflected, and this results in a disruption of any intended accuracy or attempt at even coverage. Also, any debris caught in the holes can be simply pushed through and into the interior of the wand where it can be flushed out the end. The device of this invention th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com