Method for improving dent-resistance of a steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, such embodiments of the present invention are described in detail with reference to the accompanying drawings.

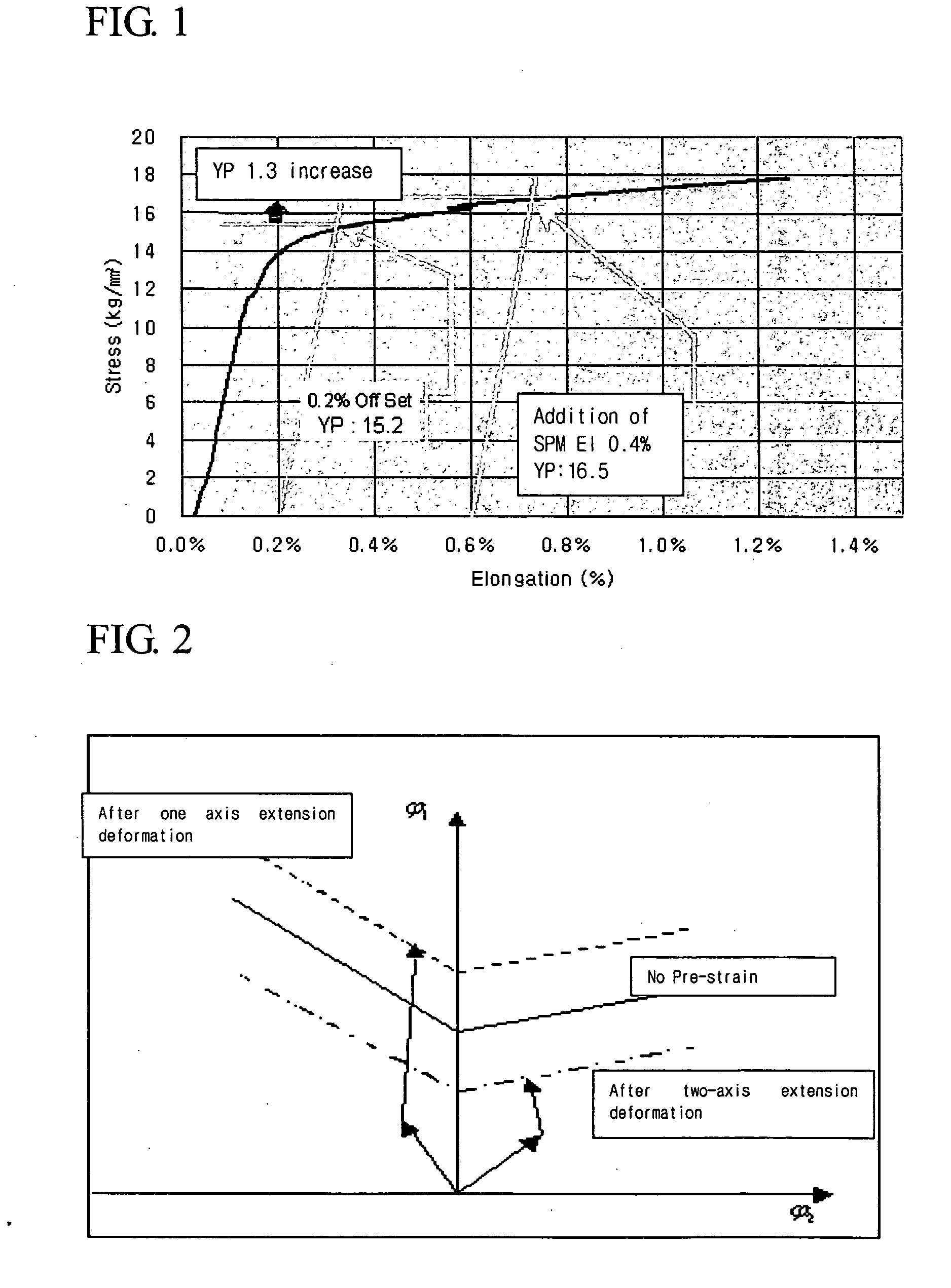

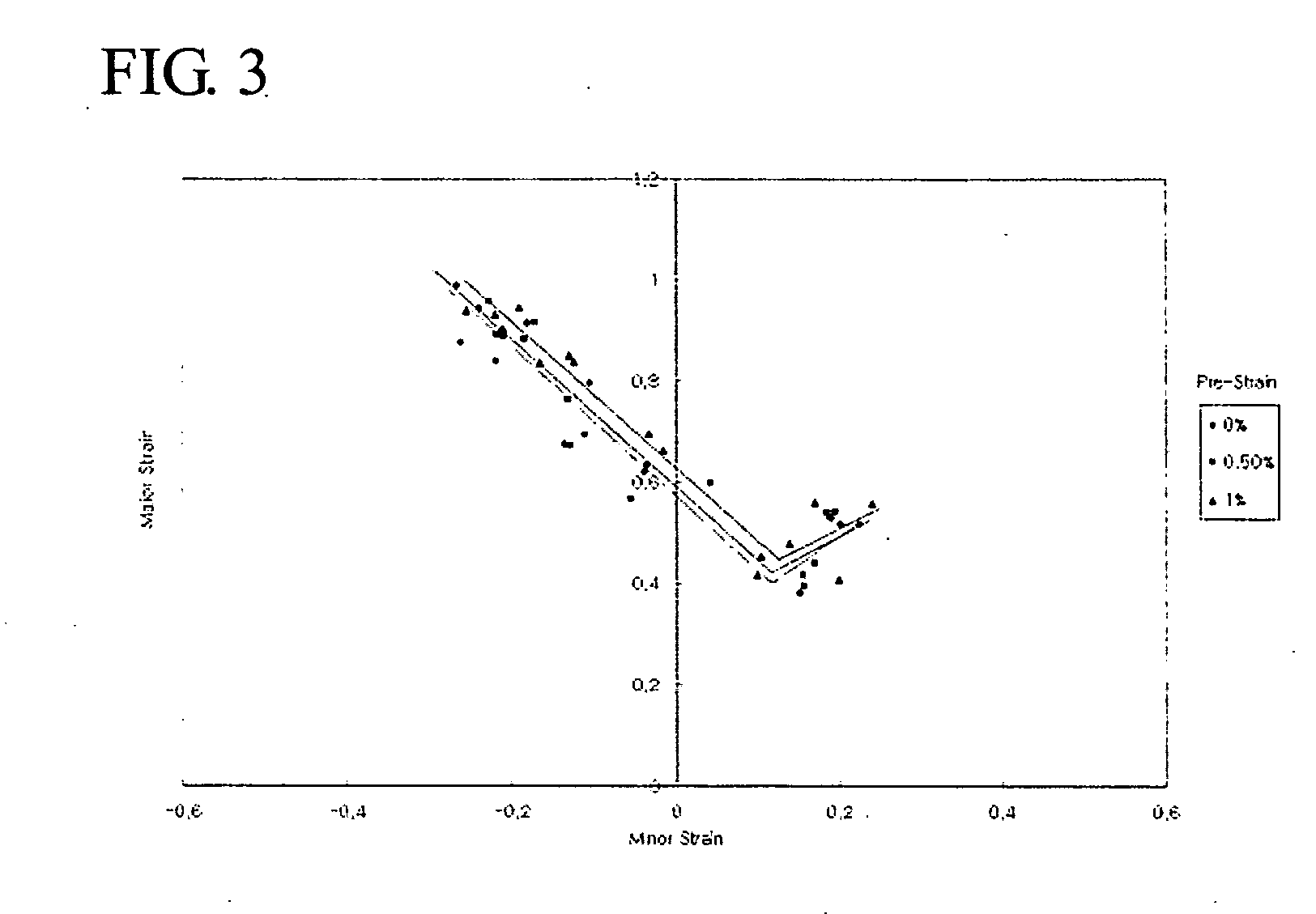

[0017] In the methods according to the present invention, there are provided a few methods such as a method of applying a pre-strain during a skin pass mill process for enhancing a forming property and a dent-resistant property of parts based on yield strength enhancement of a steel plate, and a method of enhancing a reduction rate during a skin pass mill process.

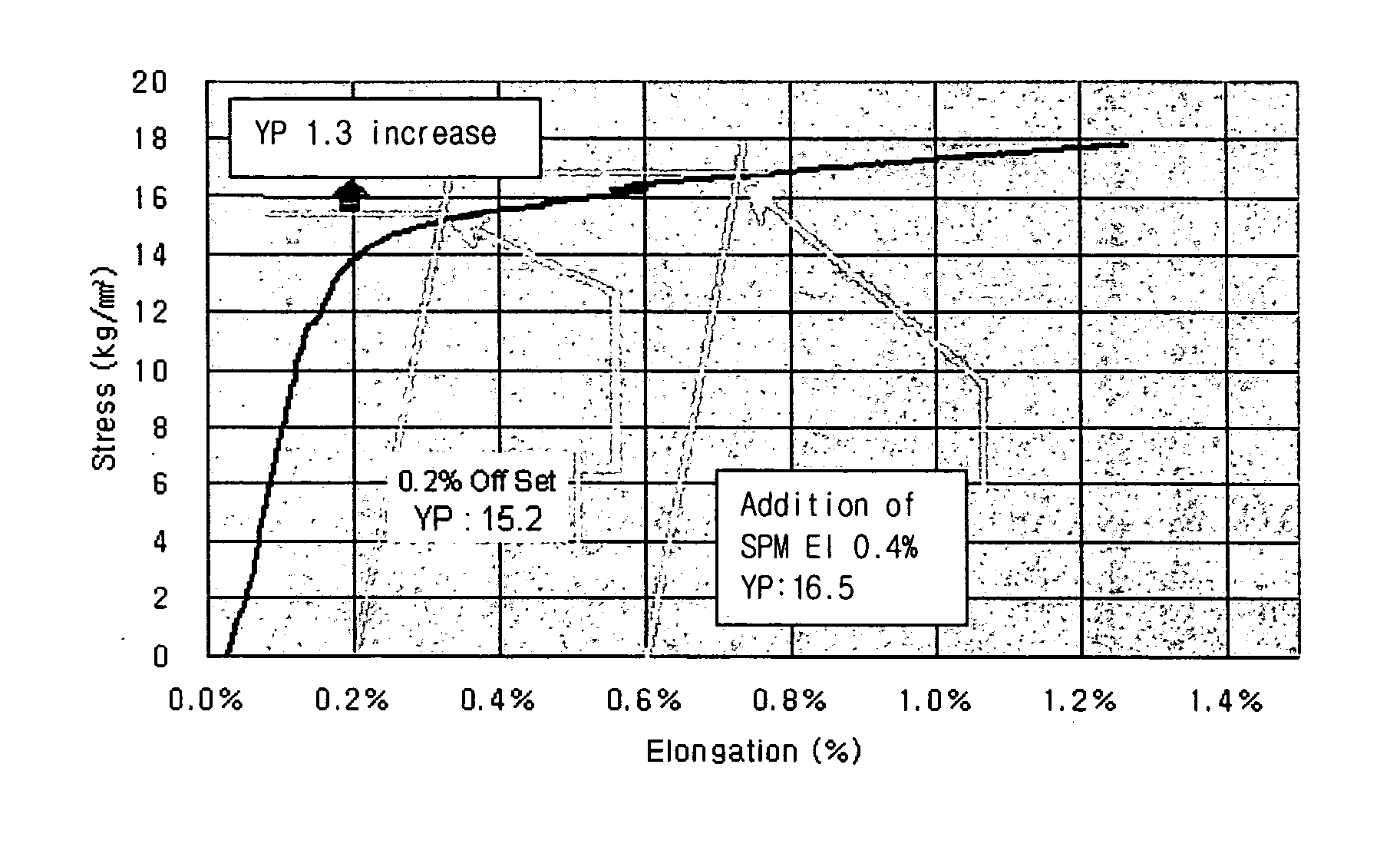

[0018] In order to enhance a dent-resistant property of a steel plate with a mechanical process, it may be required to increase work-hardening, namely, yield strength (YP), by providing a material with a pre-straining process before a press process is performed.

[0019] Applying a pre-strain to a material is directed to deforming the material before a press process is performed. The pre-straining process may be performed within a range of 5%.

[0020] Pre-straining processes are generally performe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com