System and method for pumping fluid using a pump cassette

a technology of pump cassette and fluid, which is applied in the direction of positive displacement liquid engine, liquid fuel engine, instruments, etc., can solve the problems of affecting the precision with which the cassette chamber is expanded and contracted, and the amount of fluid pumped by the cassette can be inaccura

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

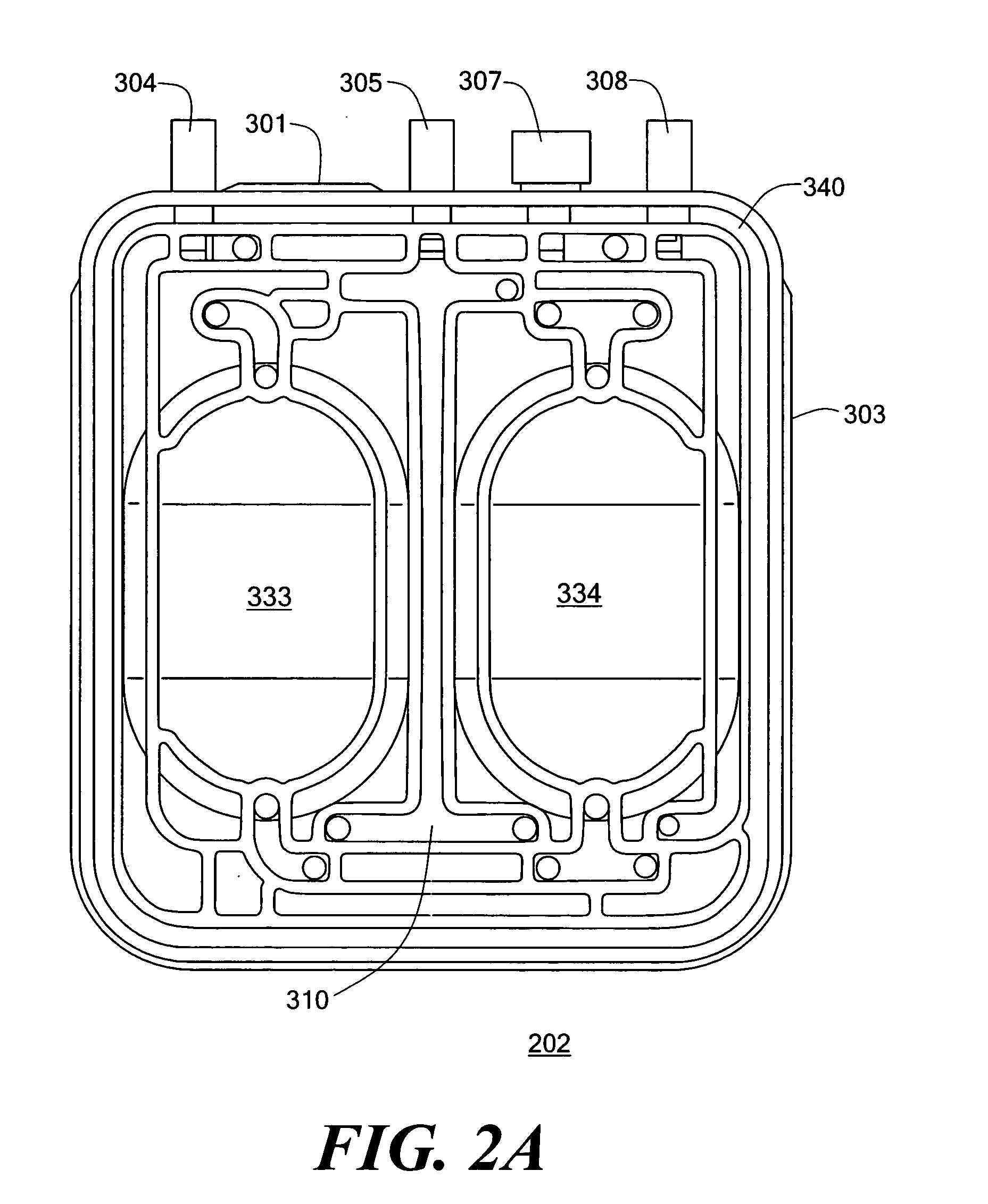

[0054] Illustrative embodiments of the present invention pump fluid using a pump cassette. The pump cassette, which is preferably pneumatically operated by a control assembly, includes various combinations of membrane-based chambers and valves. During use, the control assembly is pressed in close face-to-face contact against the pump cassette, and precisely actuates the membrane-based chambers and valves to regulate fluid flow through the cassette. A force assembly ensures that an adequately sealed, face-to-face contact is maintained between the control assembly and the pump cassette. To those ends, the force assembly includes a movable member capable of applying a continuous force to the pump cassette to press the pump cassette against the control assembly. Details of various embodiments are discussed below.

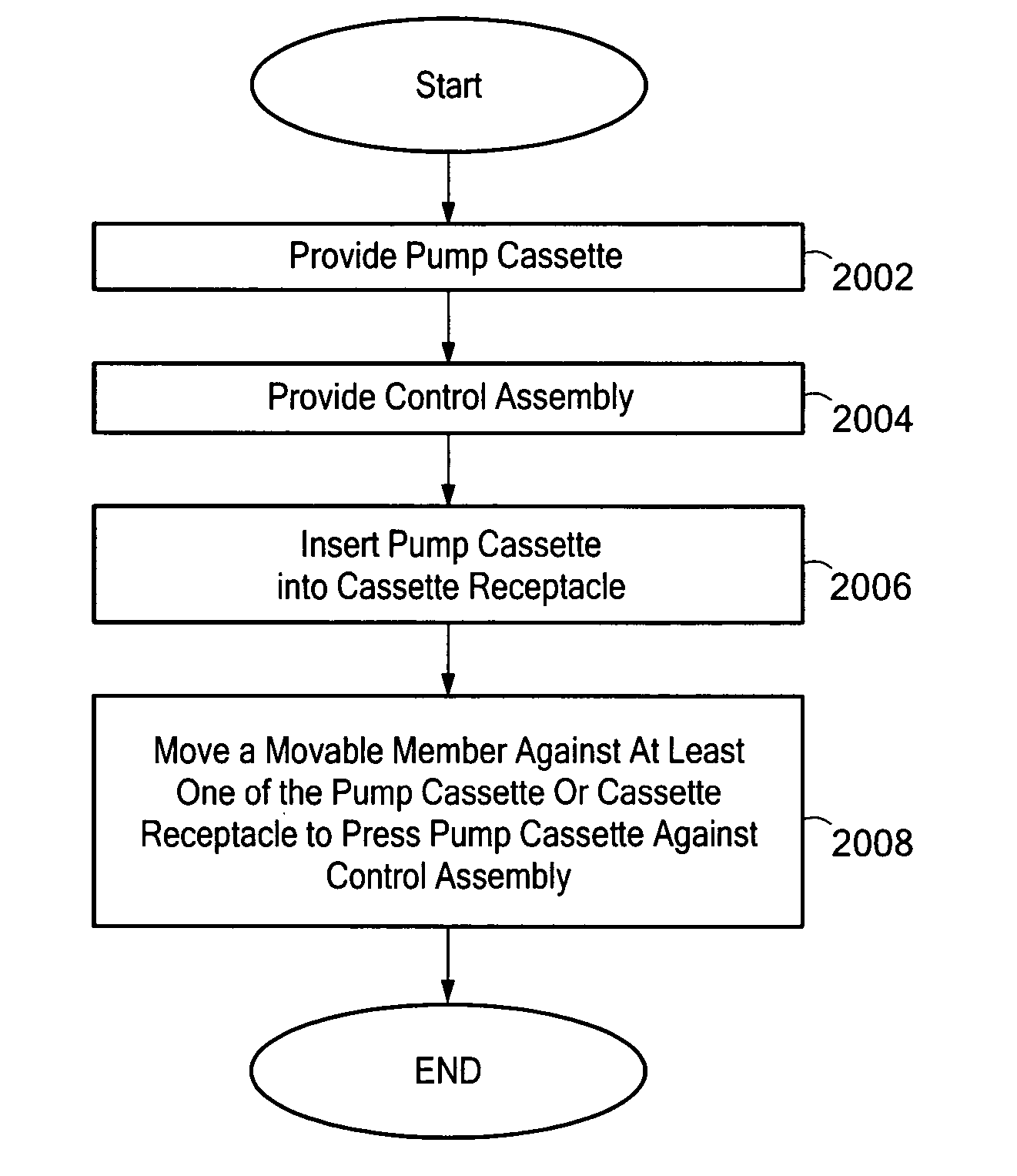

[0055]FIG. 1 is a process flow diagram describing a process 2000 for pumping of fluid using a pump cassette, in accordance with one embodiment of the invention. Beginning in bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com