Side pull-resistant slide for zipper

a pull-resistant slide and zipper technology, applied in the field of zipper slides, can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

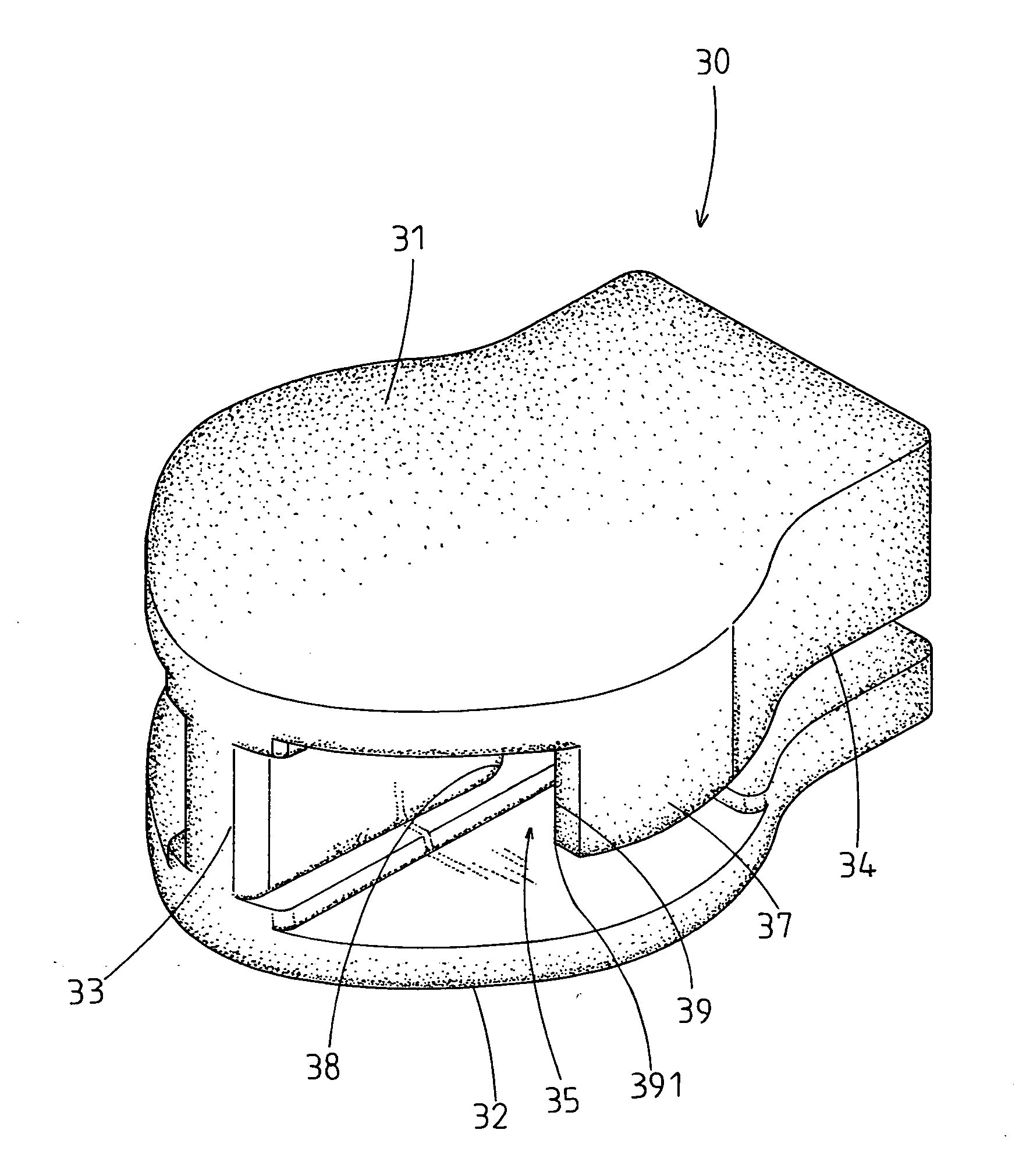

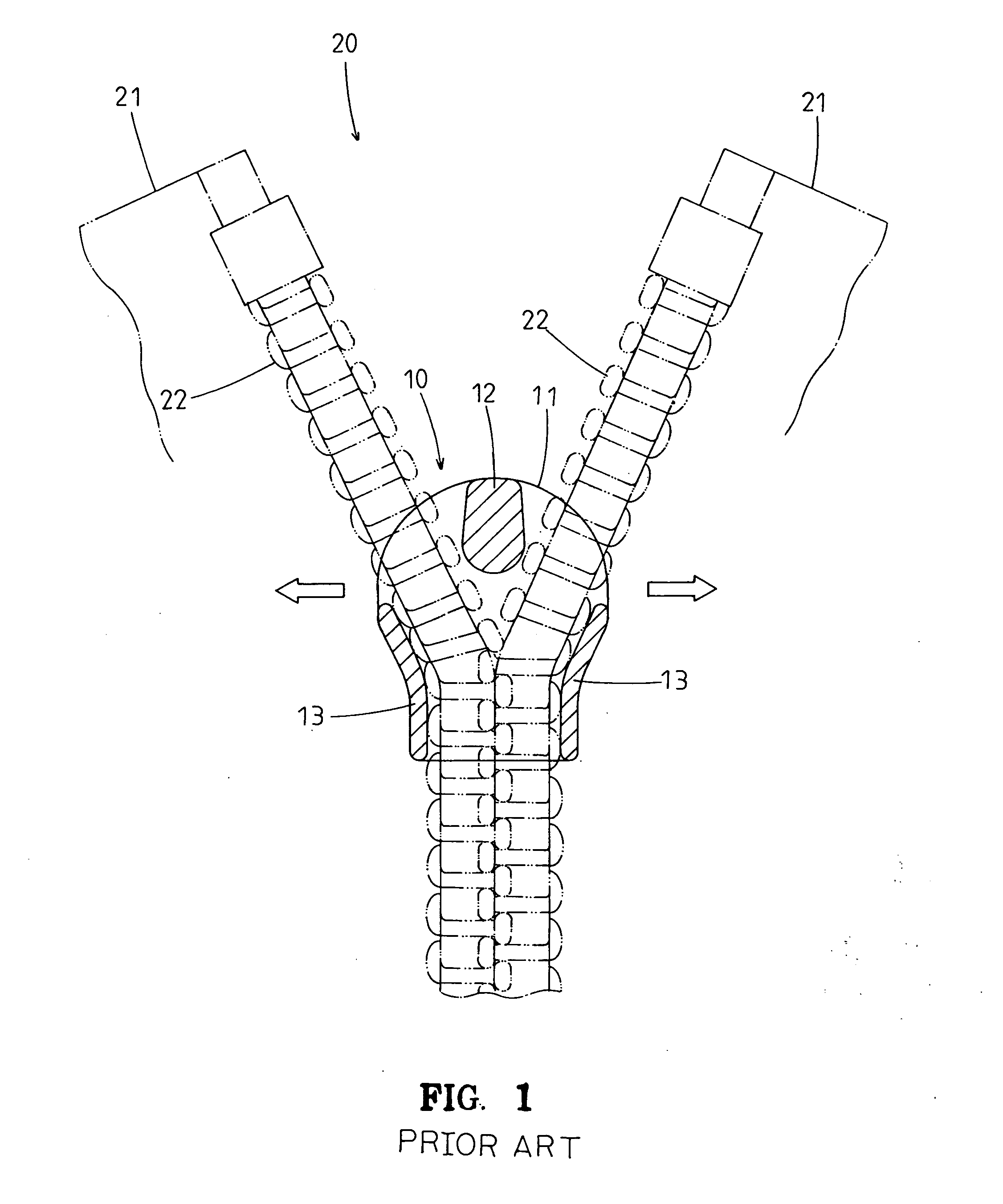

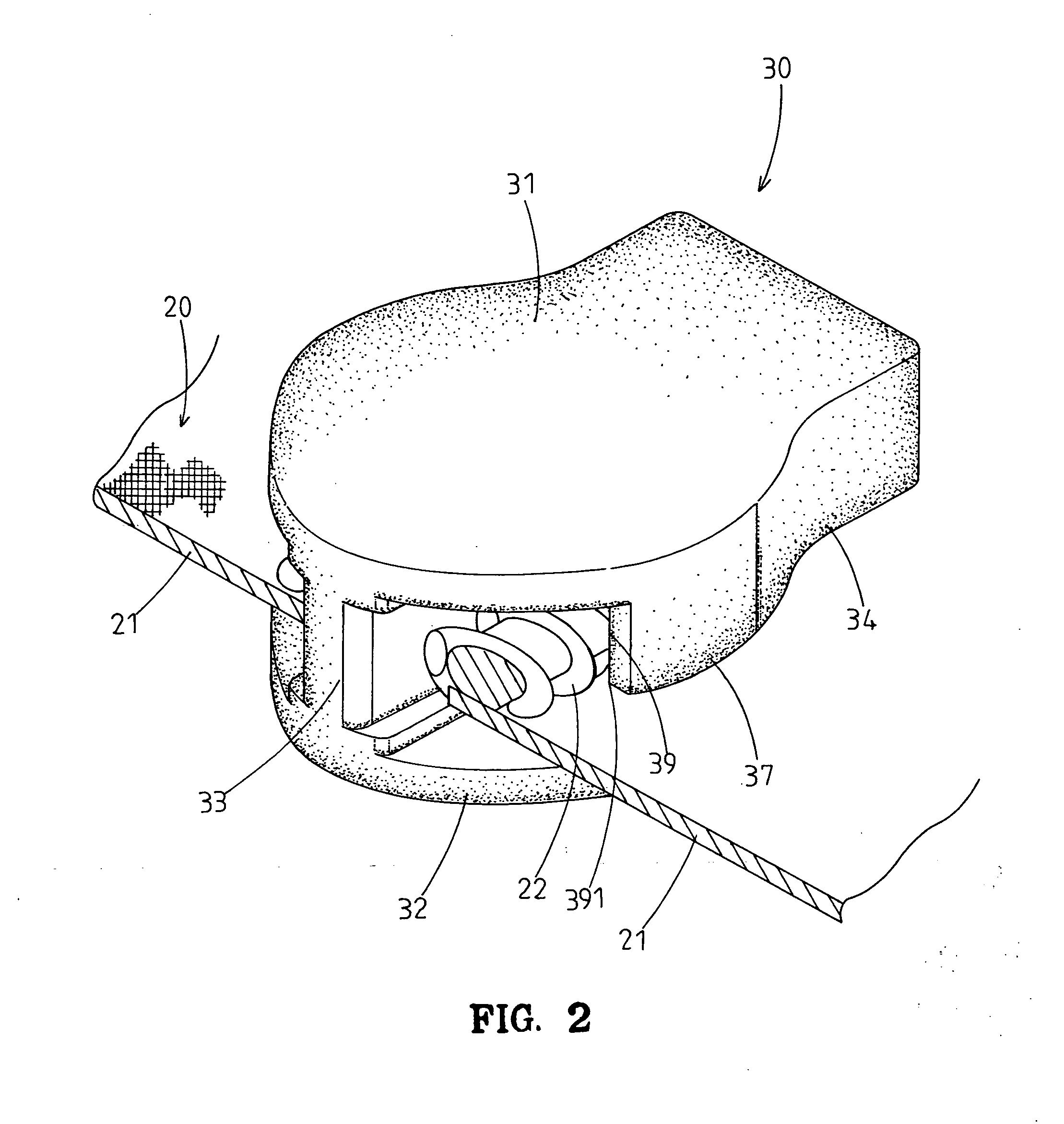

[0033] Referring to FIGS. 2 through 4, a zipper with a side pull-resistant slide in accordance with the present invention is designated by 20 and comprises two tapes 21 and a slide 30. Each tape 21 includes a row of helically arranged teeth 22 sewn to a lateral edge thereof. The slide 30 includes two opposed boards 31 and 32 each having a first end and a second end. The slide 30 further includes a central guide 33 for connecting the first ends of the opposed boards 31 and 32. The second end of at least one of the opposed boards 31 and 32 include two flanges 34 respectively extending along two lateral edges thereof toward the other board 32, 31. In the illustrated embodiment, the second end of the upper board 31 includes two flanges 34 respectively extending along the lateral edges of the upper board 31 toward the lower board 32, defining a substantially Y-shaped channel between the boards 31 and 32 and the central guide 33 to allow passage of the lateral edge and the teeth 22 of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com