Adjustable hanger system and method

a hanger system and adjustable technology, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of complex and questionable reliability of the prior art adjustable hanger system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

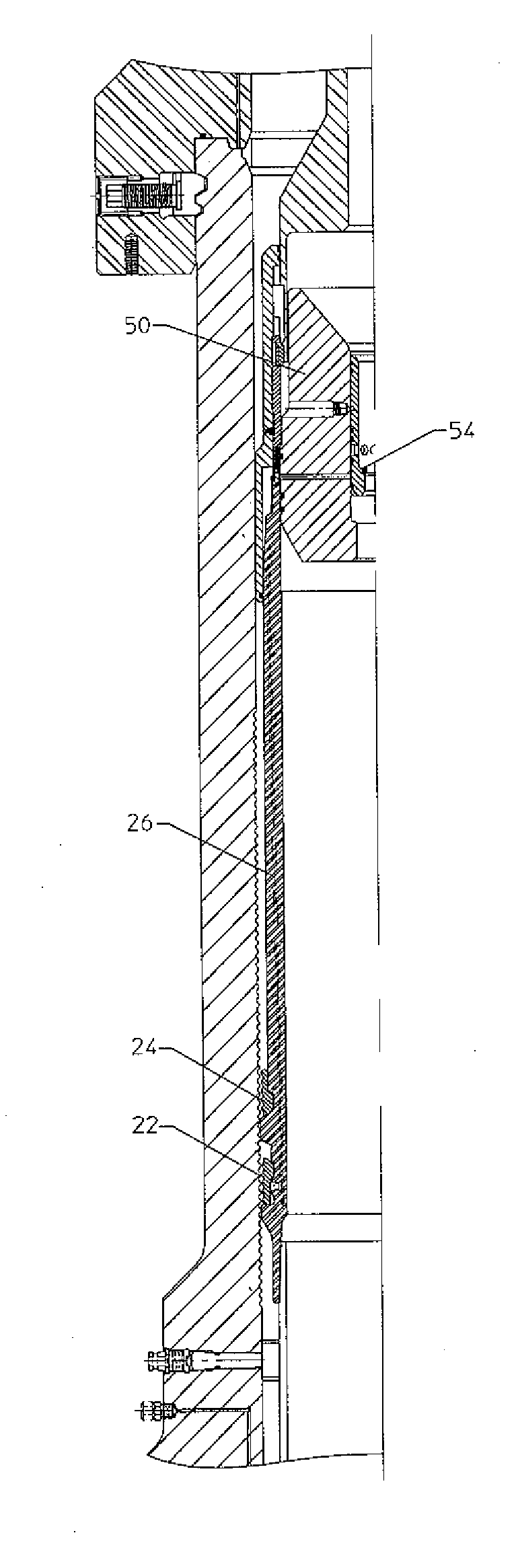

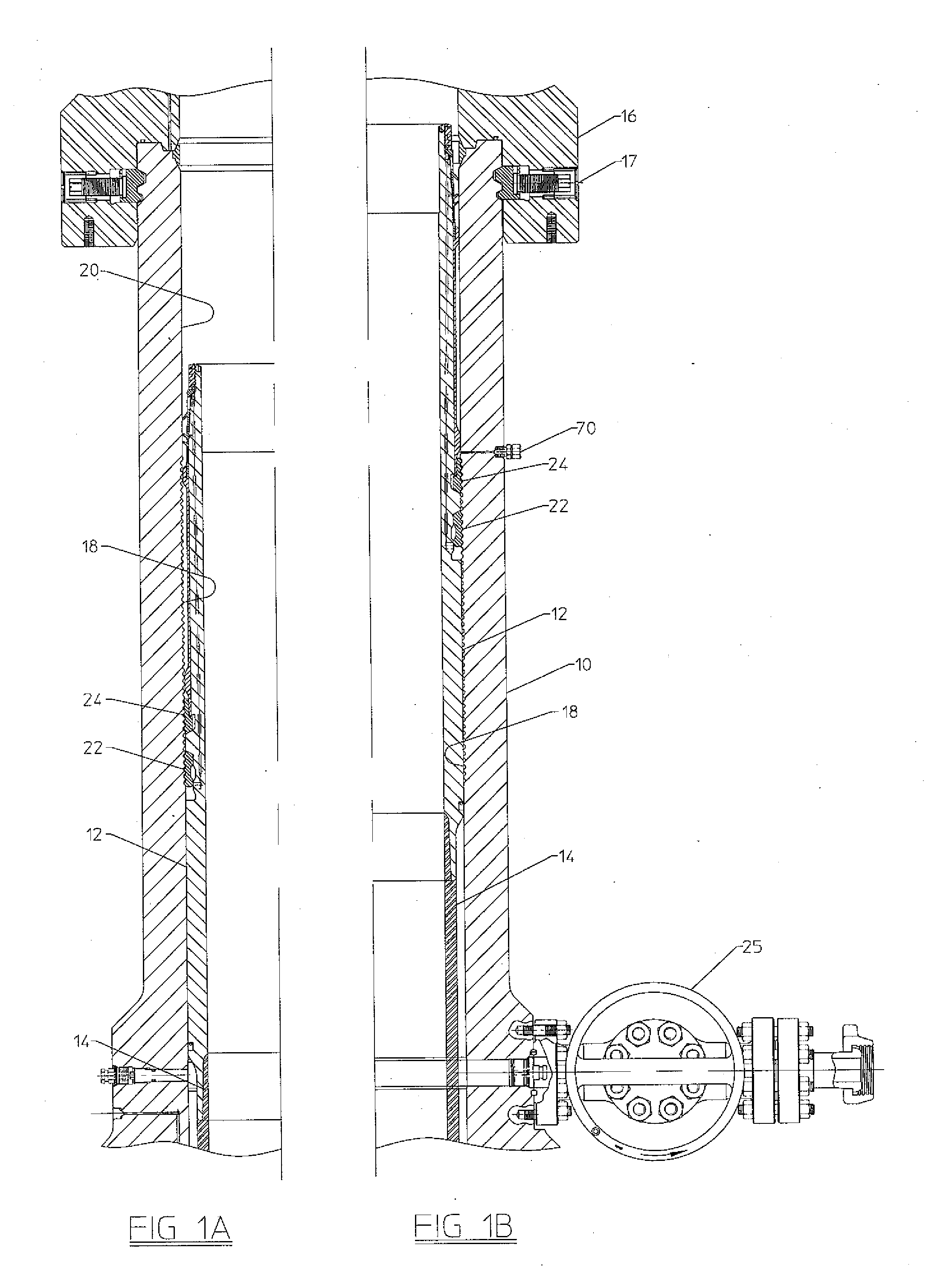

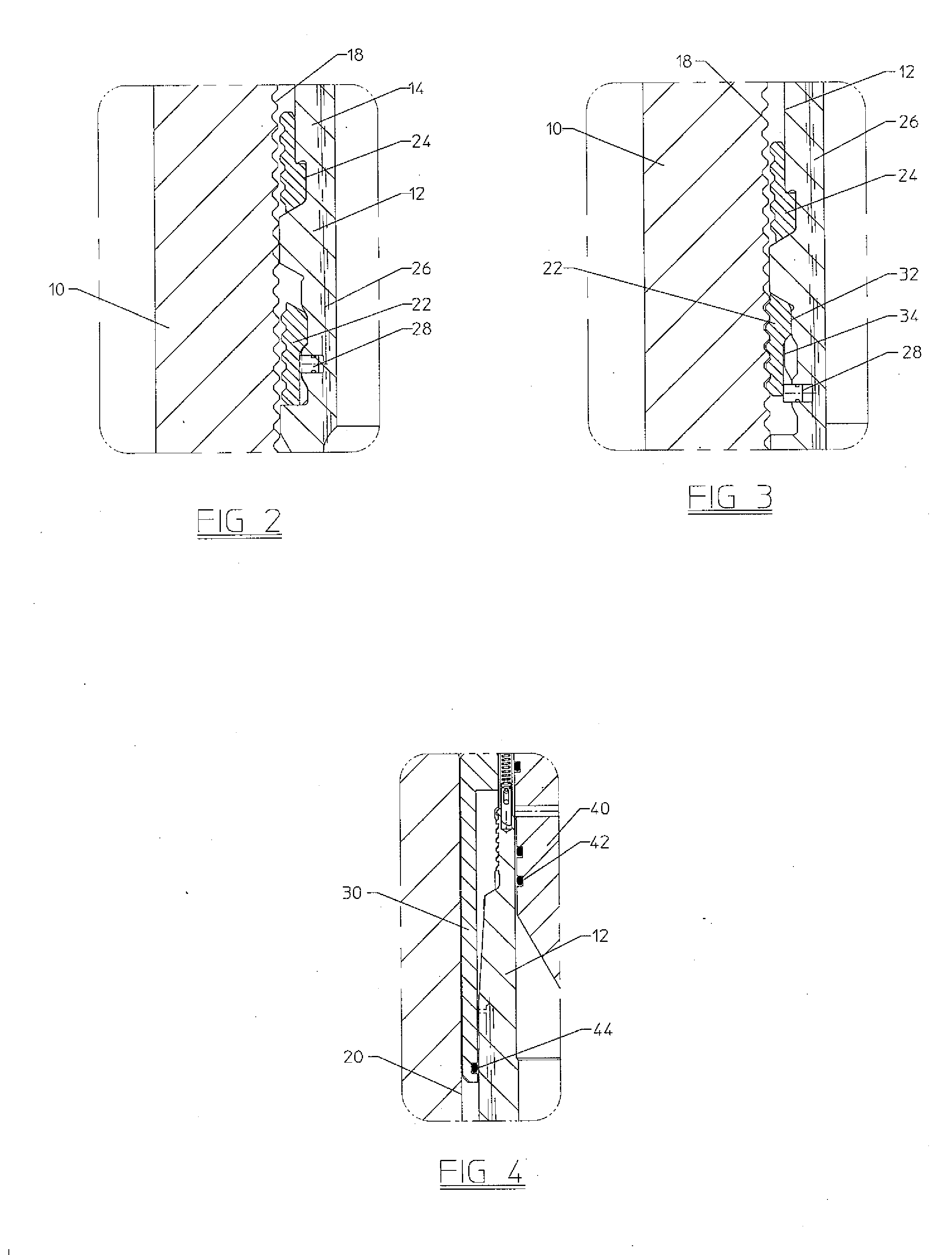

[0020]The hanger system disclosed herein provides an axial elongate sealing surface on the interior of the wellhead housing above an axially spaced plurality of grooves on the wellhead housing. Regardless of the position of the hanger with respect to the grooves, a seal will seal between the hanger and the cylindrical sealing surface above the plurality of grooves, and the hanger will be axially secured to the wellhead housing to provide the desired tension in the tubular string supported in the well from the hanger.

[0021]The hanger system allows for very fine adjustment of the position of the hanger relative to the wellhead, thereby obtaining fine adjustment of the tension applied to the tubular extending downward from the hanger. For many applications, the axially spacing of the grooves will be one-quarter inch or less. Because the grooves have the same groove profile and axial spacing, the support ring and the lockdown ring will fit within any of the selected grooves, which is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com