Track system for modular storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

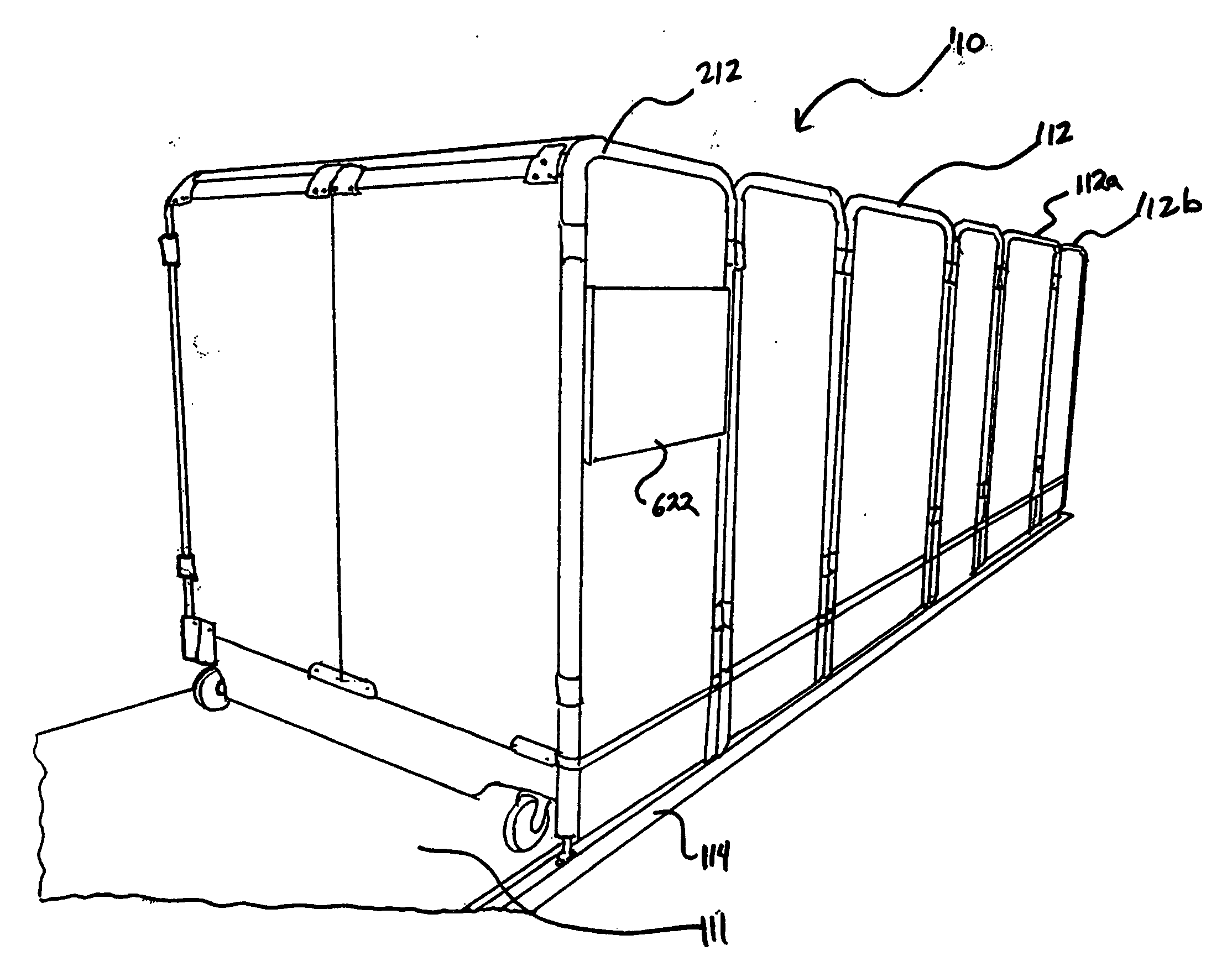

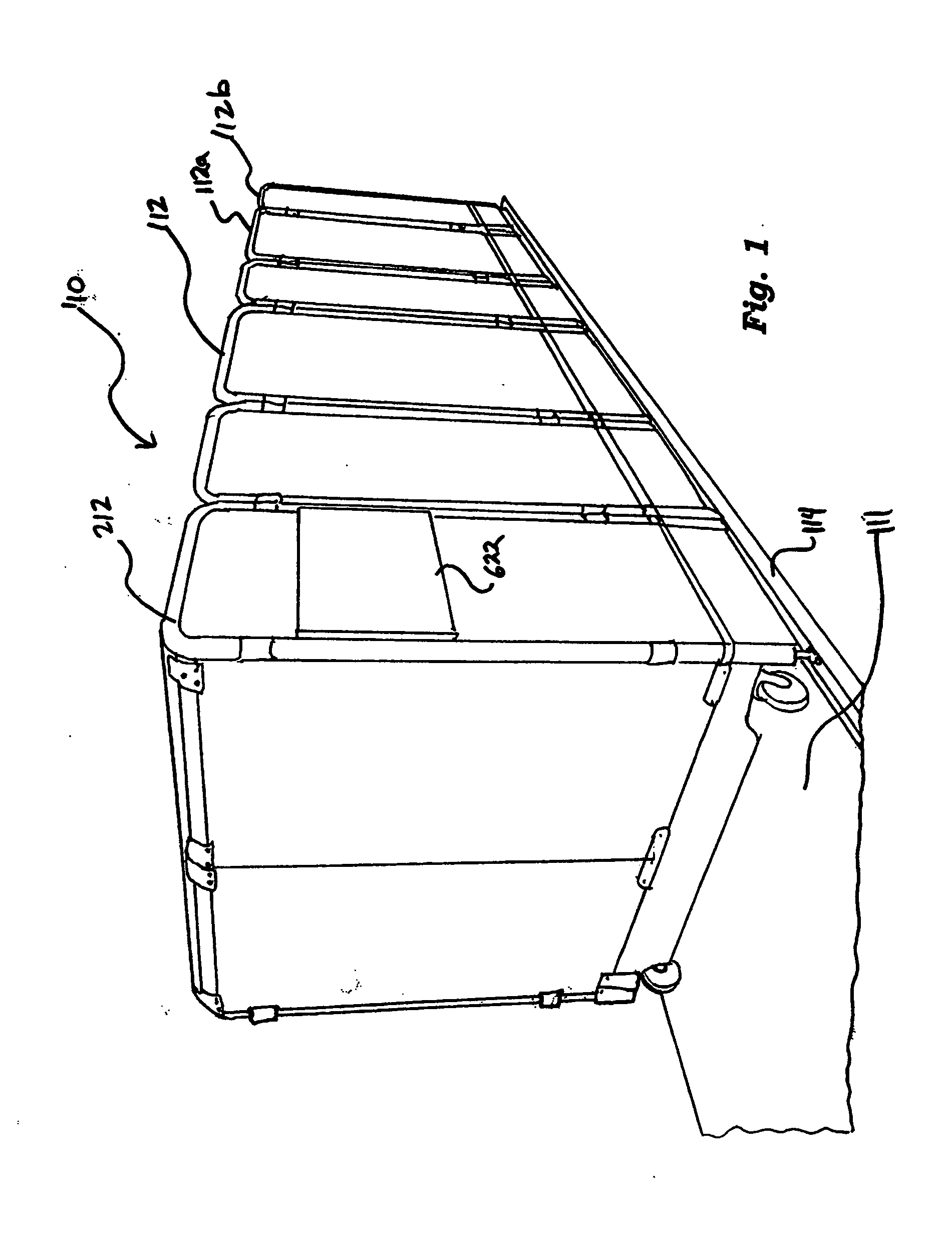

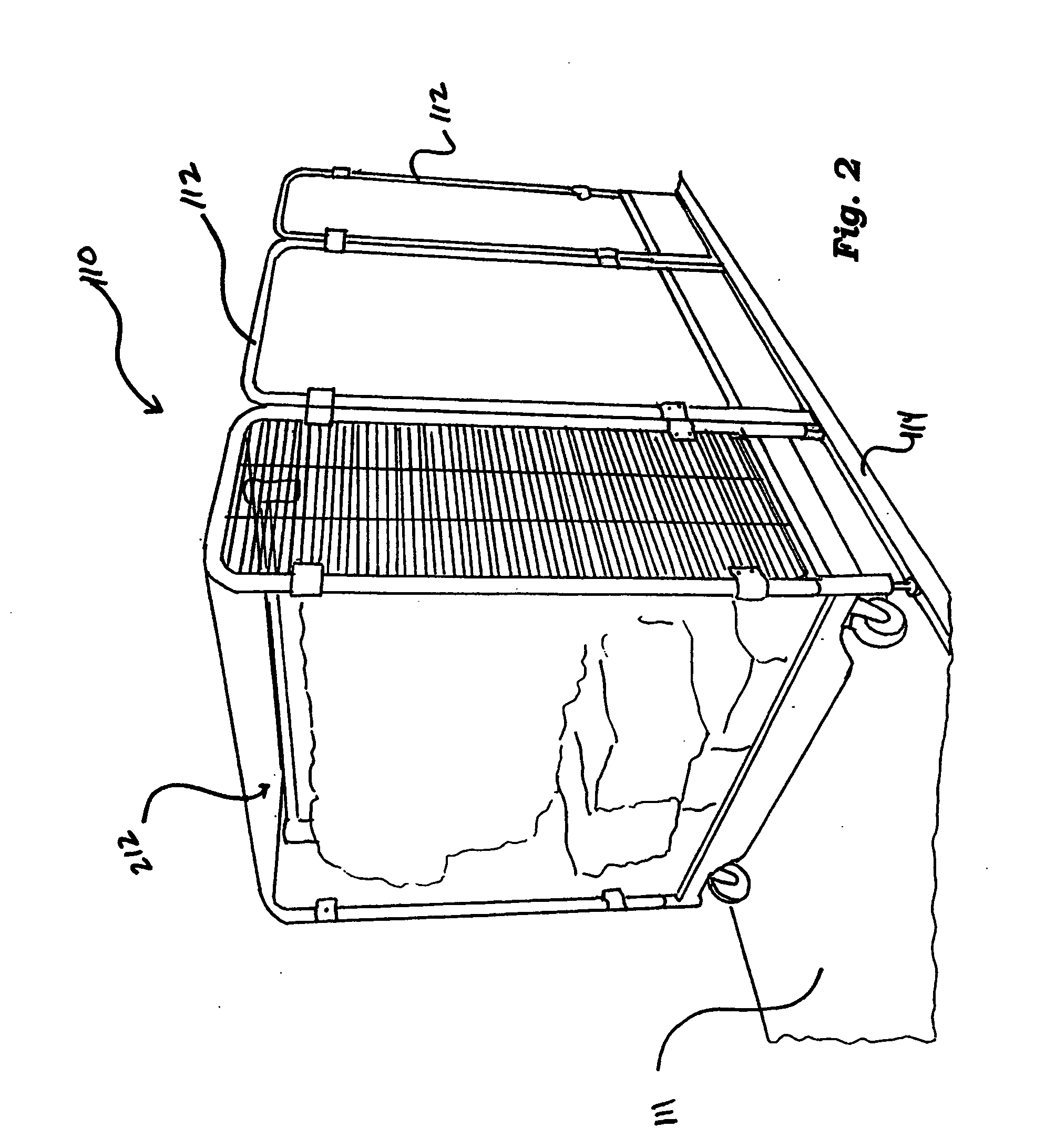

[0153] As depicted in FIGS. 1-3, a modular storage system 110 according to an embodiment of the present invention generally comprises a track 114 and a plurality of carts 112, 212. In a preferred embodiment, the carts 112 are arranged in a storage facility along a single track 114. The storage facility can be a retrofitted area of an already existing facility or the storage facility can be designed and implemented into a newly constructed facility. In an already existing facility, the track 114 is preferably positioned onto and connected to a pre-selected portion of a floor. In a newly constructed facility, the track 114 is preferably integrated directly into or onto a newly formed floor.

[0154] The modular storage system as depicted in FIG. 1 includes a mixture of retained carts 112 (as shown in FIG. 3) and modular carts 212 (as shown in FIG. 55). As can be seen in FIG. 3, the retained carts 112 populated with uniforms and equipment are preferably movable by manual force in a direc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap