Two piece console and seat assembly

a two-piece, console technology, applied in the direction of chairs, vehicle components, vehicle arrangements, etc., can solve the problems of affecting the assembly process, affecting the assembly quality, and affecting the installation technique of automated seats, so as to improve the assembly characteristics and improve the shipping profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

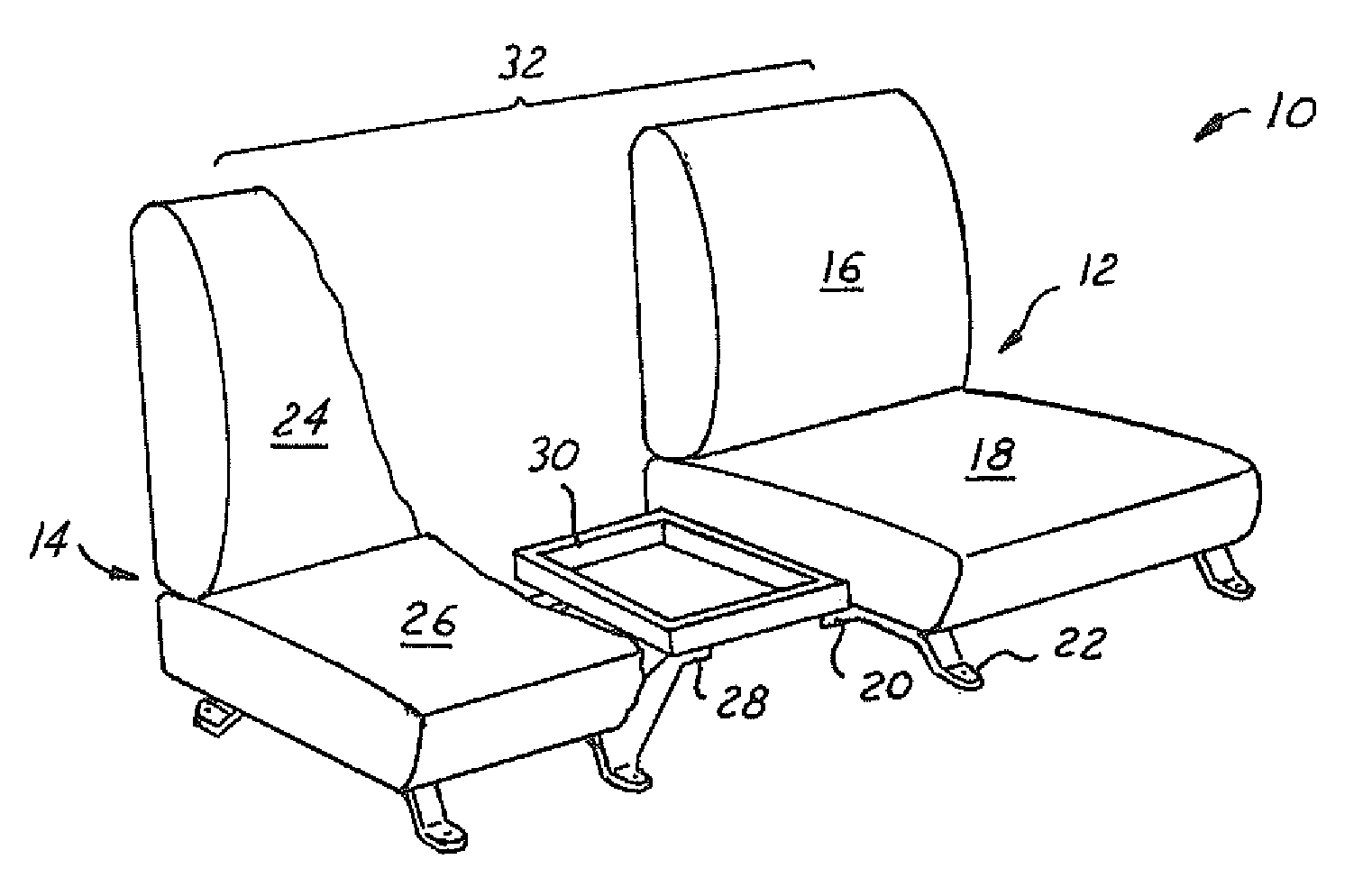

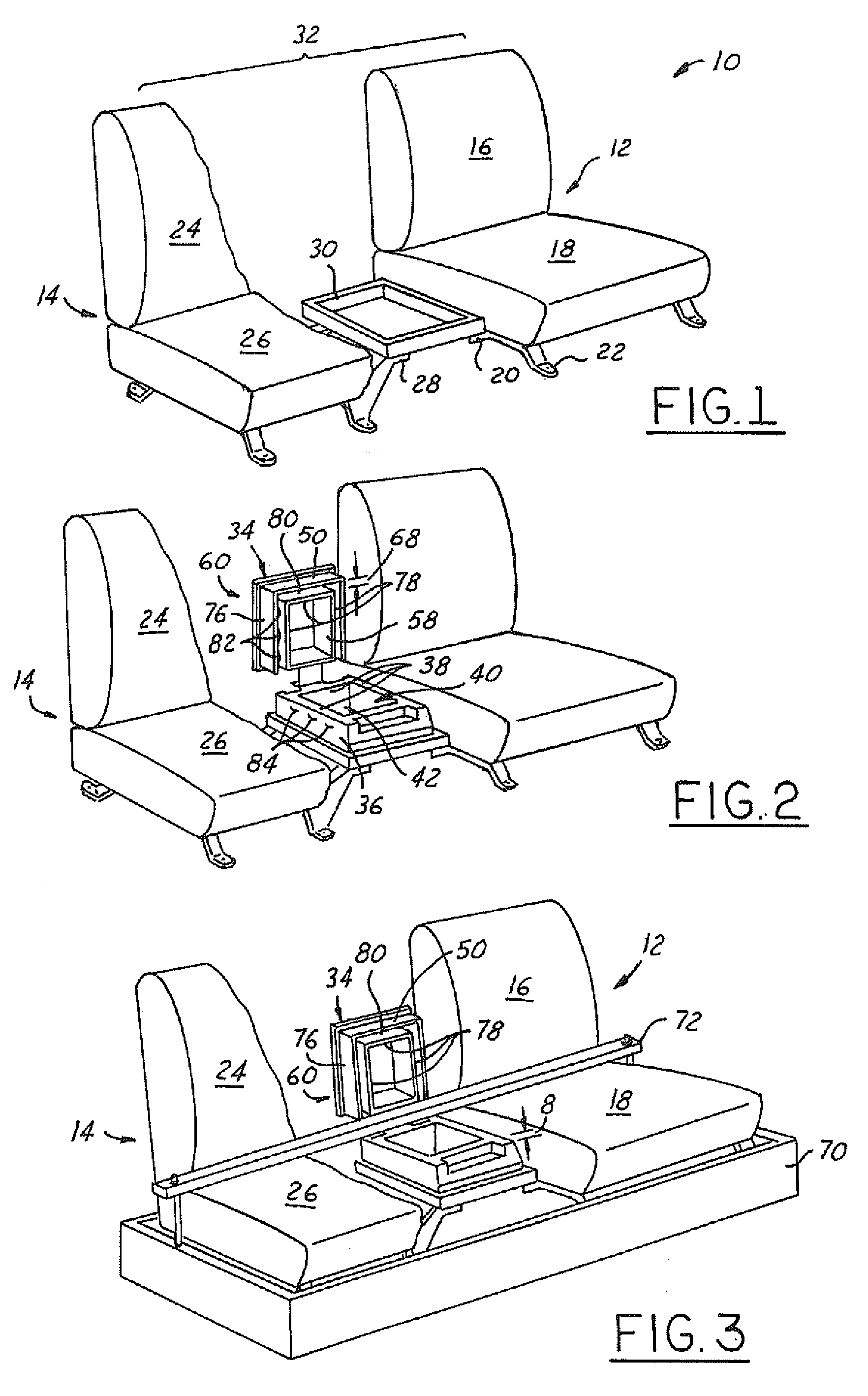

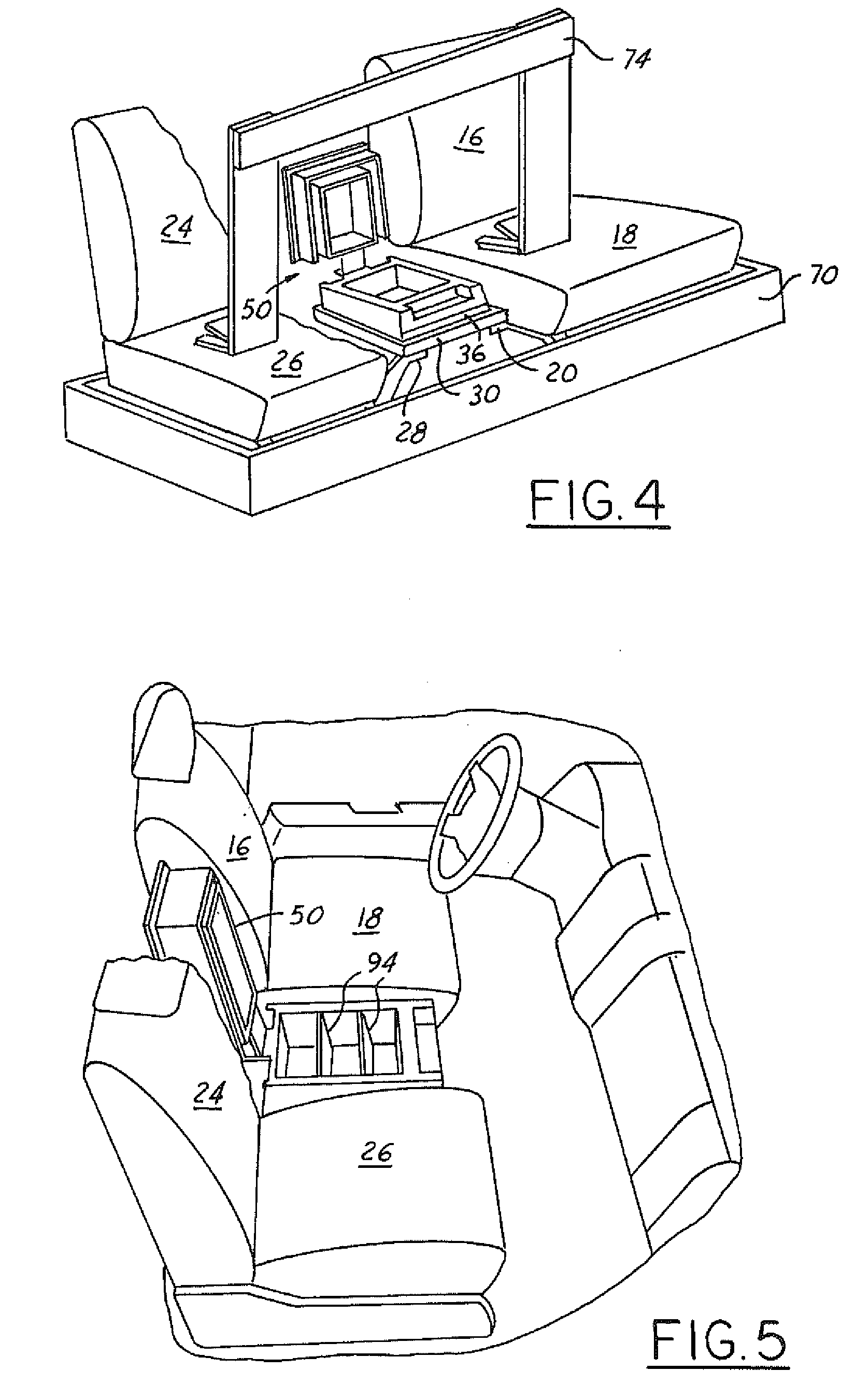

[0016] Referring now to FIG. 1, which is an illustration of an automotive seat assembly 10 in accordance with the present invention. It should be understood that the seat assembly 10 illustrated in FIG. 1 is intended to be illustrative of a wide variety of seating designs. The seat assembly 10 includes a first (driver side) seat 12 and a second (passenger side) seat 14. The driver side seat 12 is comprised of a driver seat back portion 16 and a driver seat base portion 18. A driver inboard mount assembly 20 protrudes inboard from the driver side seat 12. Although a variety of driver inboard mount assemblies are contemplated, one embodiment contemplates the driver inboard mount assembly 20 being formed as an extension of the driver seat mounts 22. Similarly, the passenger side seat 14 is comprised of a passenger seat back portion 24, a passenger seat base portion 26, and a passenger inboard mount assembly 28.

[0017] A joining frame 30 is mounted to the driver inboard mount assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com