Method and apparatus for movable structure having alternative accessible sides

a technology of accessible side and movable structure, which is applied in the field of storage structures, can solve the problems of space loss, waste of space, and loss of space in the front of the cabinet, and achieve the effects of improving rotational storage, saving space, and saving spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following description, for purposes of explanation, numerous specific details are set forth to provide a thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that these specific details may not be required to practice the present invention.

[0044] In the following description of the embodiments, substantially the same parts are denoted by the same reference numerals. Also, while references such as top, bottom and side may be used throughout the specification, it is to be understood that their orientation requirements are only to facilitate the explanation of the various embodiments and depending on the application, the top could be the side or bottom or vice versa.

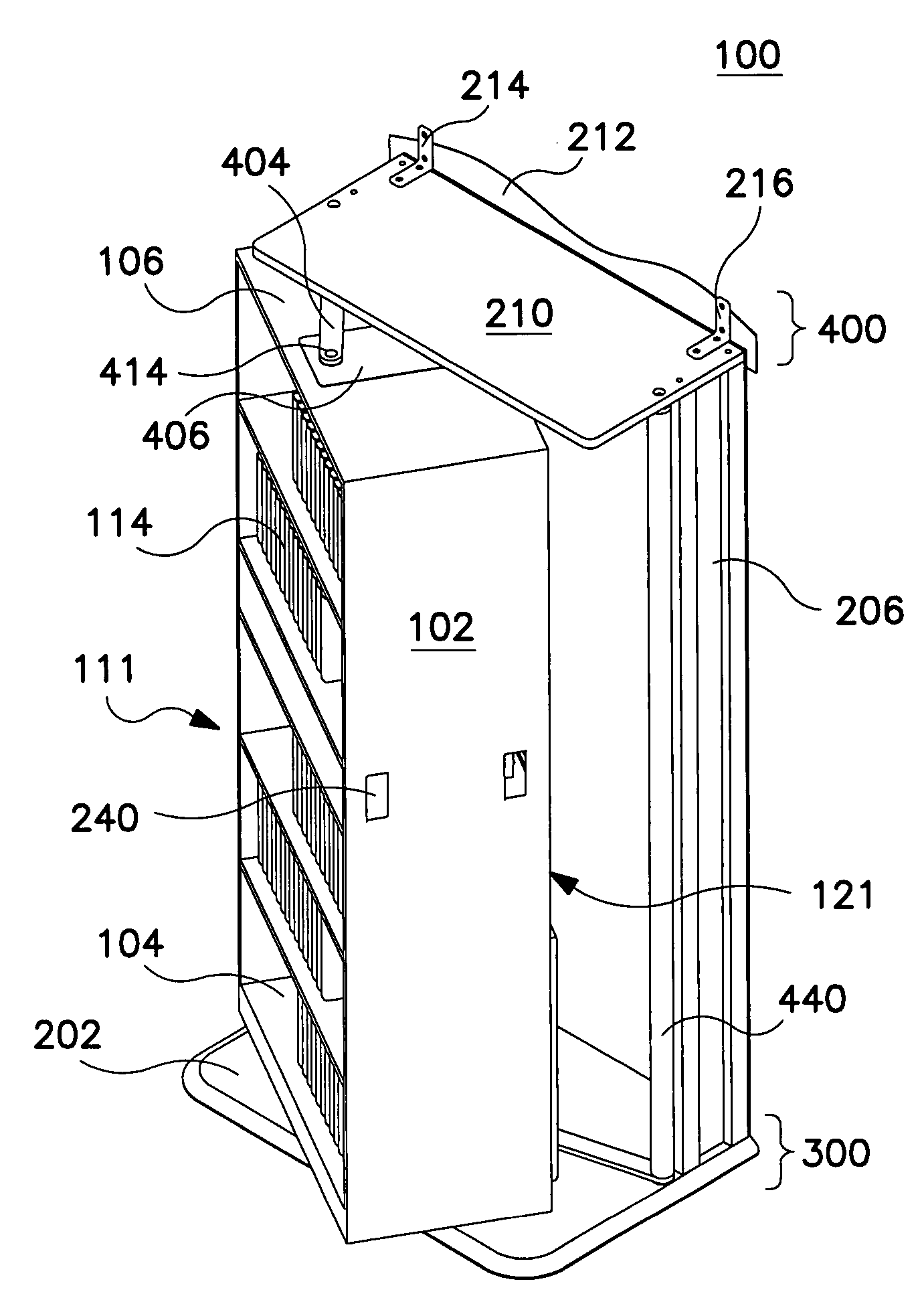

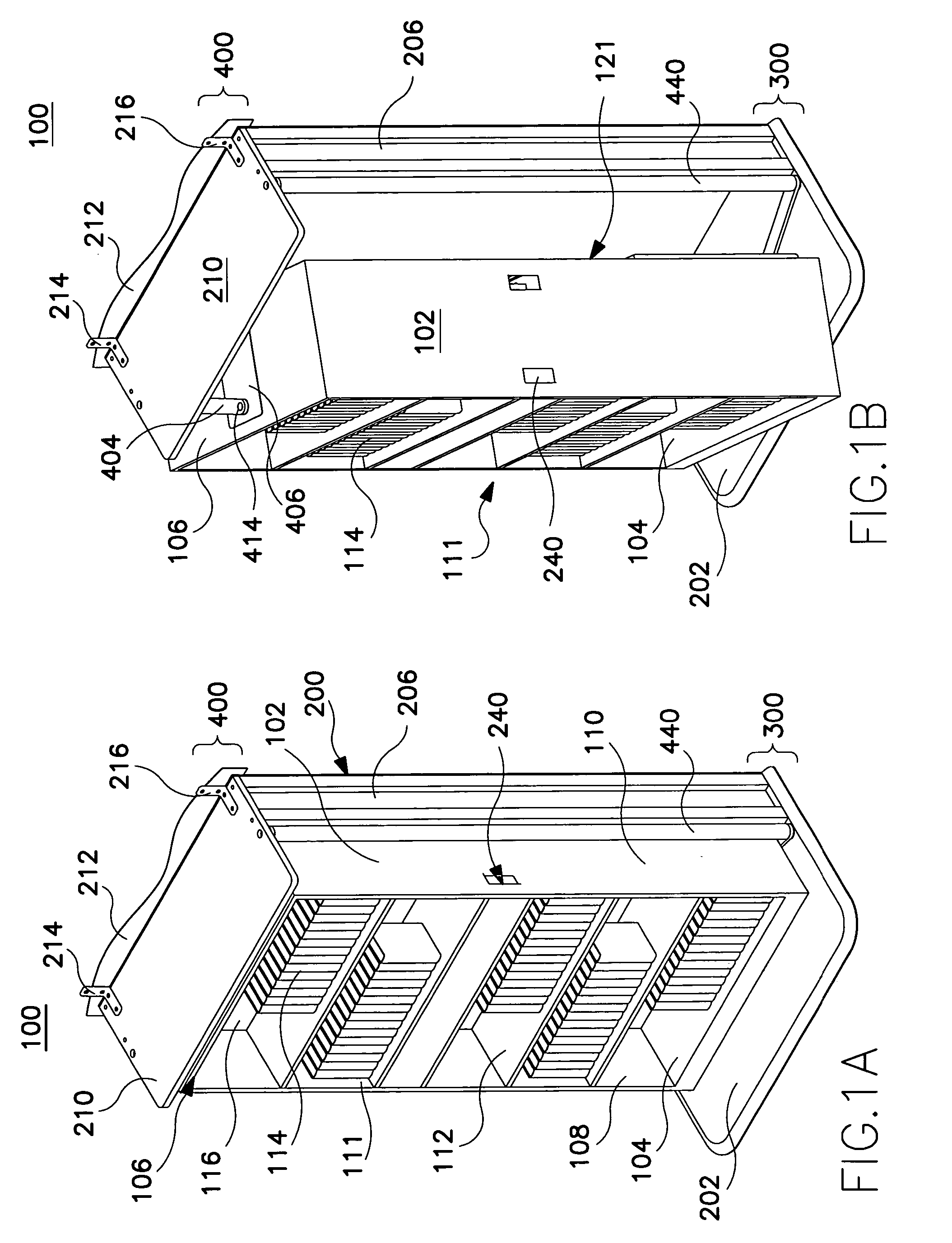

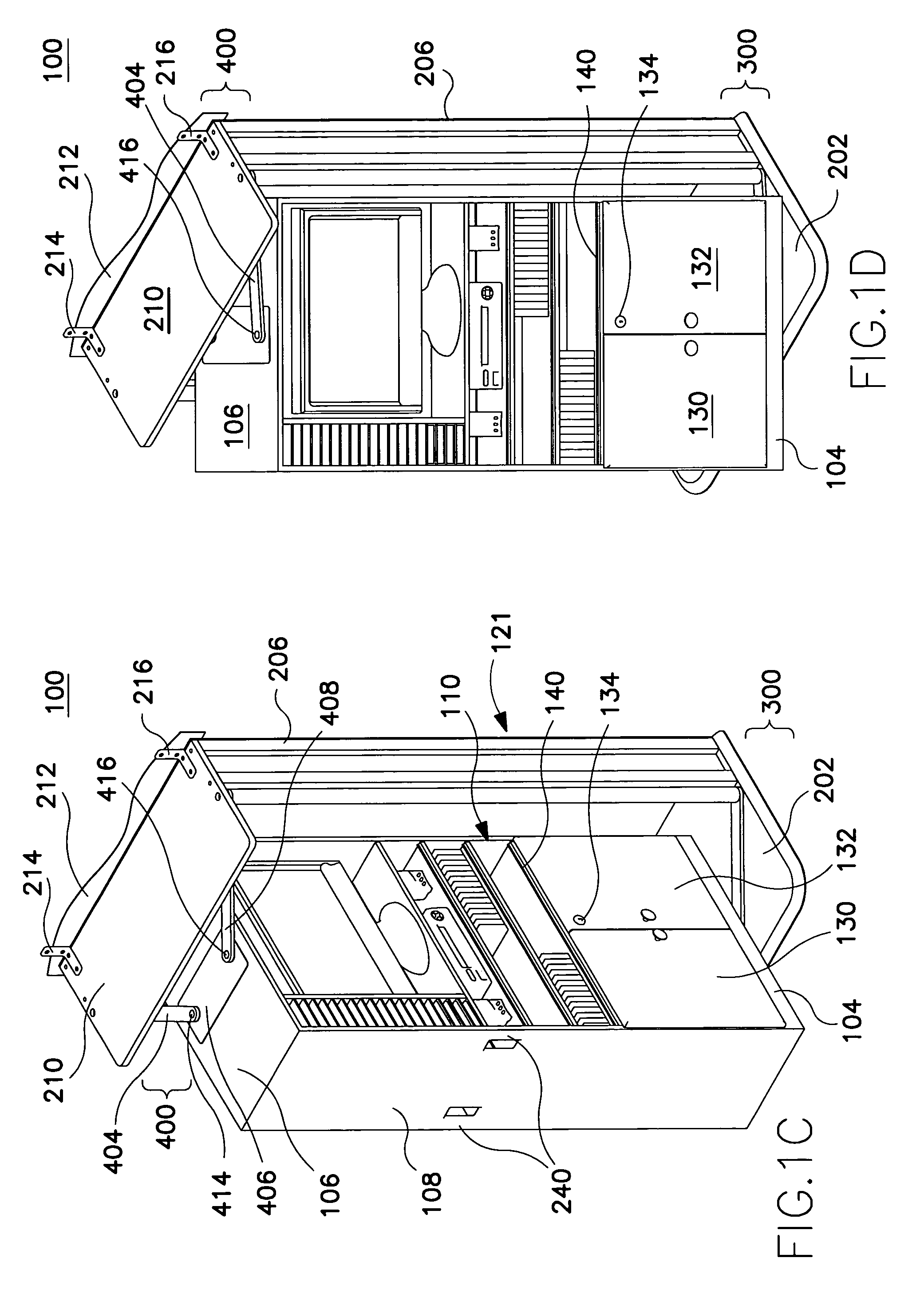

[0045] An apparatus for a reversible storage system having a moving object 102 is disclosed in the present application. The reversible storage system, in one embodiment, includes an object 102 and a frame 200. A first side of frame is situated at a substant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com