Flashing adaptable to different shapes of roof

a technology of flashing and roof, applied in the field of flashing, can solve the problems of difficult or even impossible installation of flashings, installation of flat base of pitched flashings over apertures made in tiled roofs, and installation of flat base of pitched flashings over apertures that do not have flashings, etc., to achieve efficient and versatile, easy and efficient manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

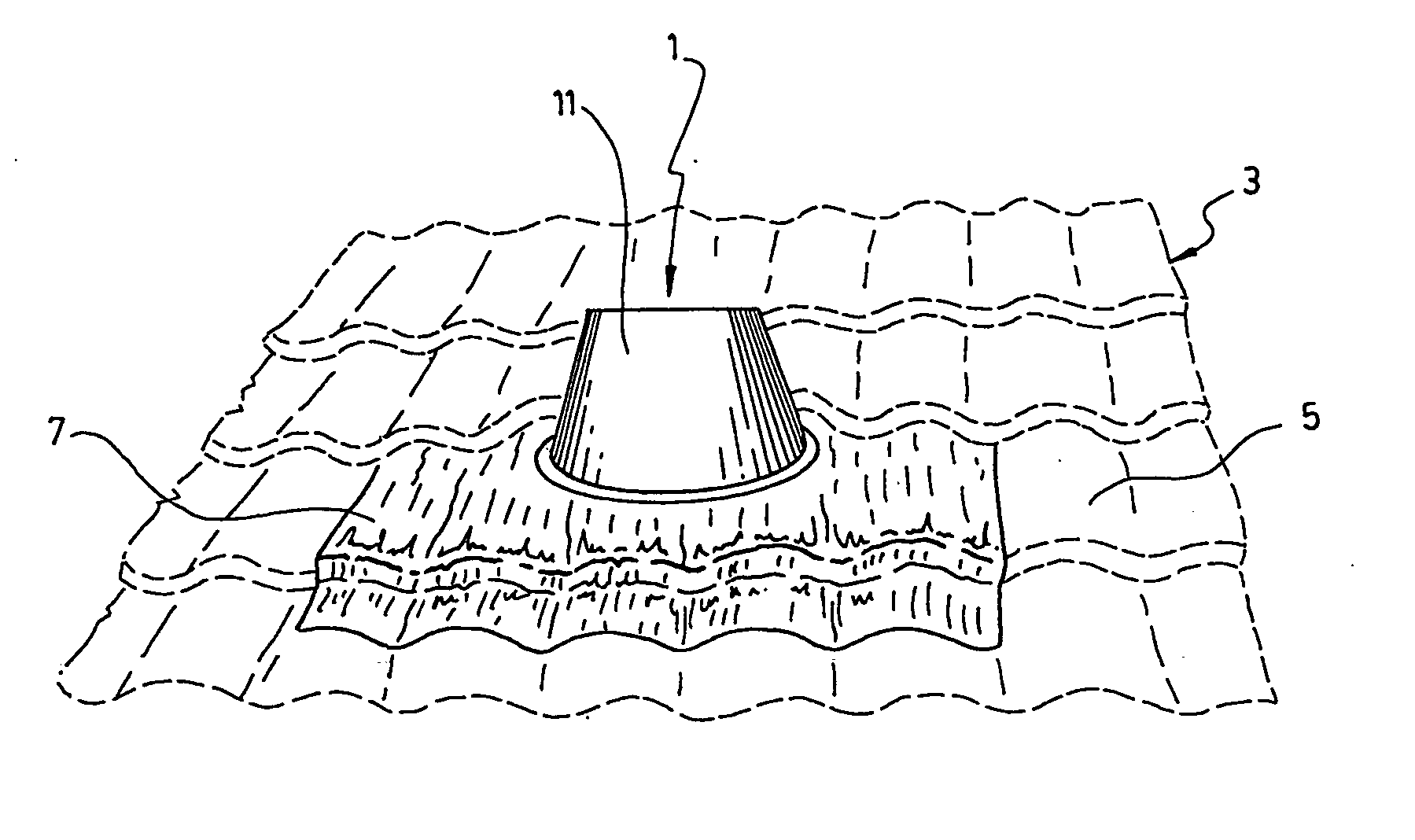

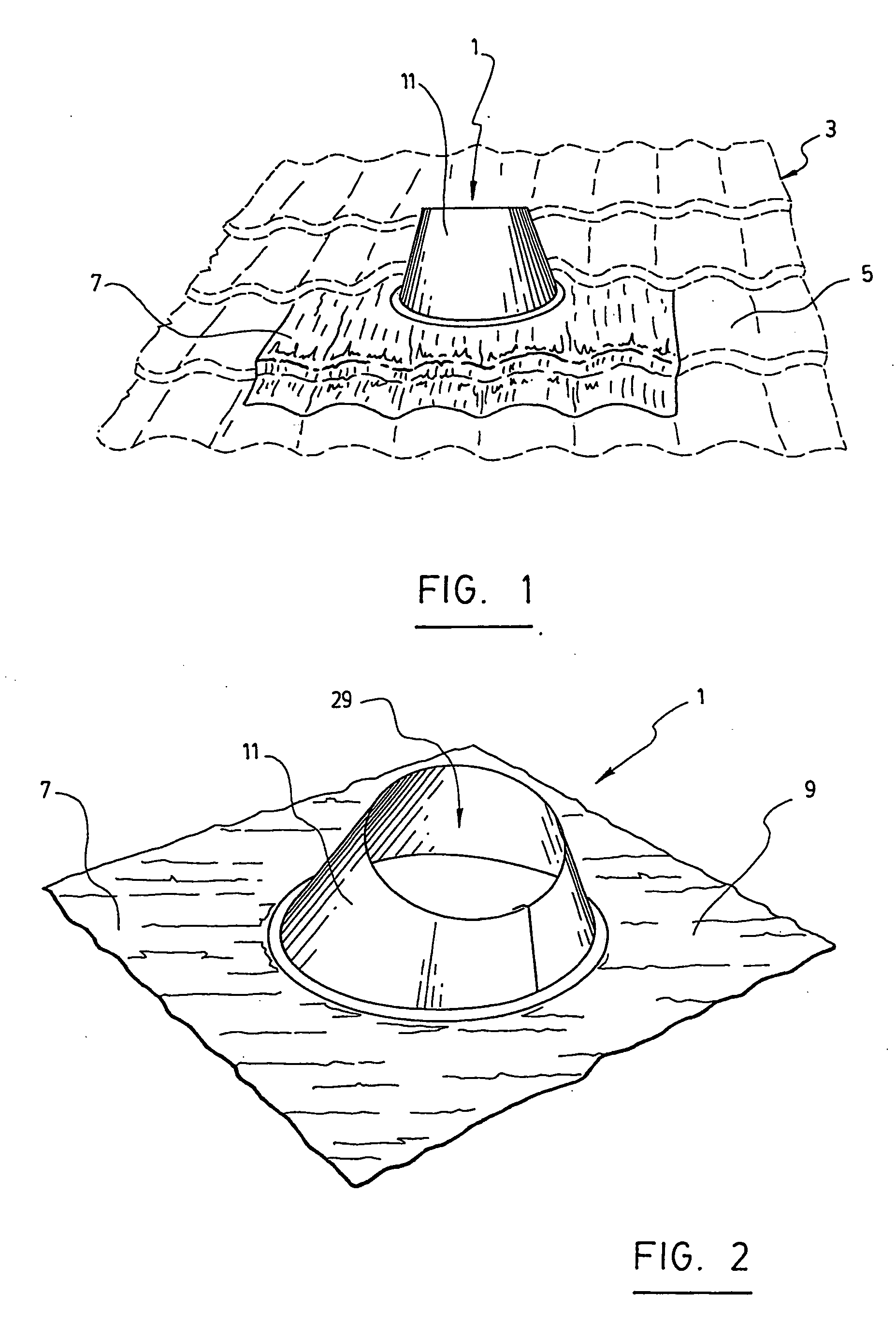

[0026] As aforesaid and shown in FIGS. 1 to 3, the flashing 1 according to the invention is intended to be used for weatherproofing the gaps that exist in-between a roof 3 and a chimney passing therethrough (or alternatively a pipe, a venting duct or any other kind of member having to pass through the roof). More particularly, the flashing 1 according to the present invention can be installed on different shapes of roof or tiles 5 thereon.

[0027] As shown in FIG. 2, the flashing 1 comprises a base member 7 adapted to be mounted over an aperture made in the roof 3 to allow passage of a chimney. The flashing 1 also comprises a surrounding member 11 extending upwardly from the base member 7 to fit around the chimney.

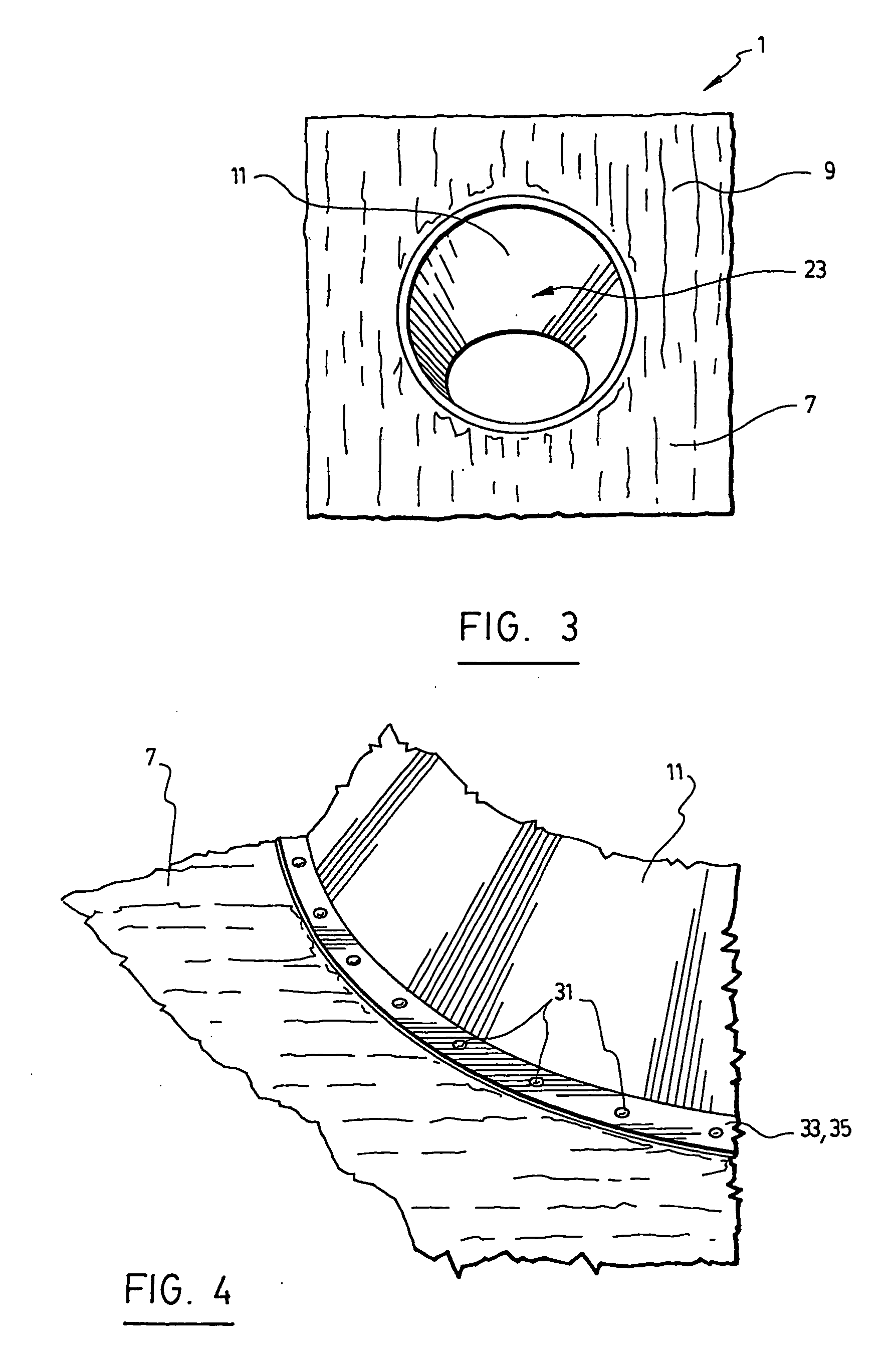

[0028] As shown in FIG. 3, the base member 7 comprises a panel 9 of generally quadrilateral shape. The panel 9 is provided with an opening 23 large enough to allow passage of the chimney therethrough.

[0029] In accordance with a further preferred aspect, the base member 7 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap