Apparatus and method for forging premium coupling blanks

a technology of forging apparatus and premium coupling, which is applied in forging/pressing/hammering apparatus, forging/hammering/pressing machines, manufacturing tools, etc. it can solve the problems of increasing the overall cost of production of premium coupling, further challenges in efficient manufacturing of premium coupling, and insufficient wall thickness of standard api coupling stock and blanks. achieve the effect of convenient or efficient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

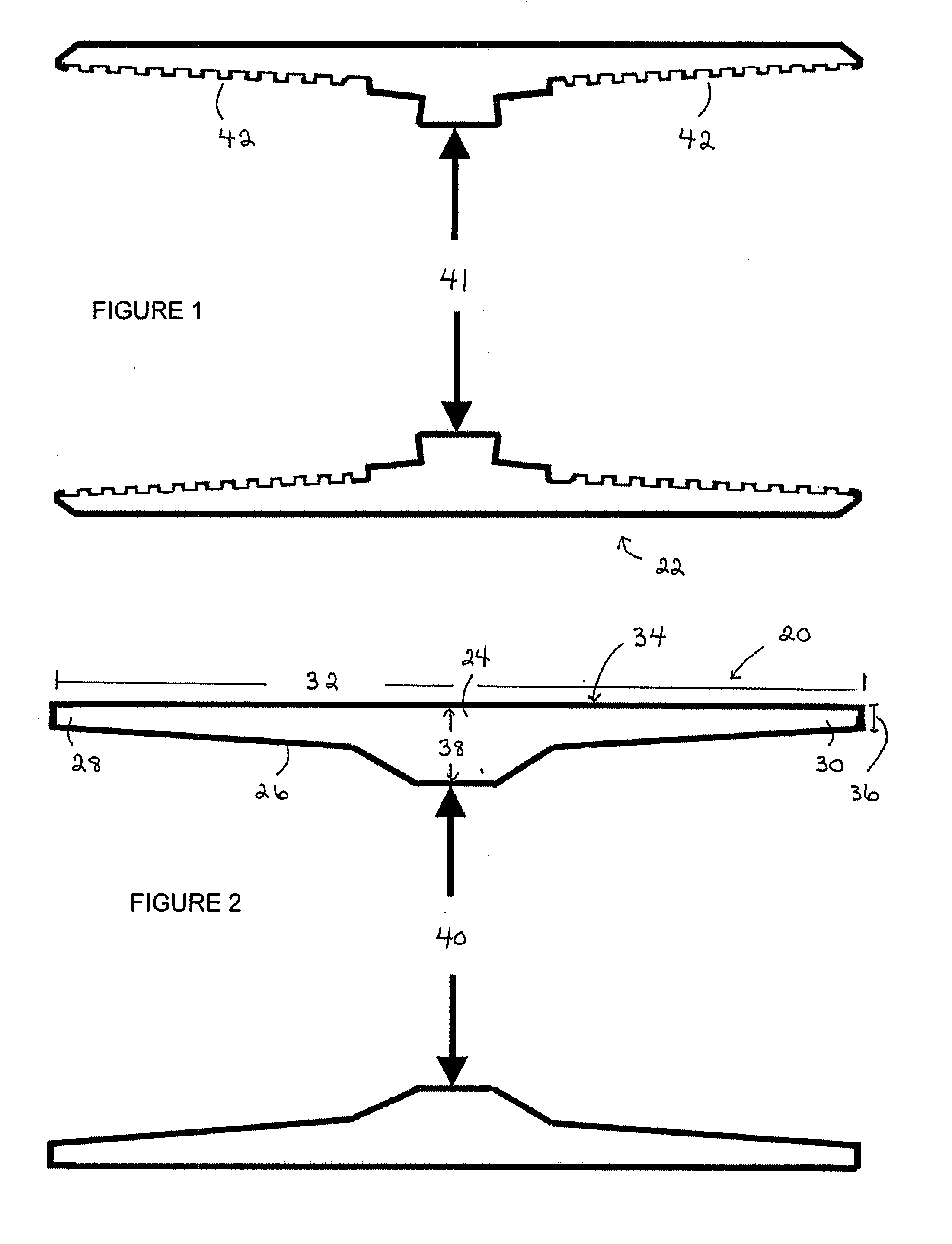

[0105]The present invention is for use in the production of a forged product (20). Preferably, the forged product (20) is a premium coupling blank as shown in FIG. 2. More preferably, the premium coupling blank (20) is an OCTG premium coupling blank suitable for the subsequent production of a premium coupling (22) therefrom, particularly an OCTG premium coupling, of the type shown in FIG. 1.

[0106]Referring to FIG. 2, the premium coupling blank (20) is comprised of a wall (24) defining a bore (26) extending therethrough between a first end (28) and a second end (30) of the premium coupling blank (20). A length (32) of the premium coupling blank (20) is defined between the first end (28) and the second end (30). As well, the premium coupling blank (20) defines a wall thickness between an outer surface (34) of the wall (24) and the bore (26). The wall thickness of the premium coupling blank (20) varies through its length (32), as shown in FIG. 2, to provide a minimum wall thickness (36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| interface | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com