Rotatable control lever mount

a technology of lever mount and lever, which is applied in the direction of mechanical control devices, instruments, cycle equipment, etc., can solve the problems of reducing the service life of the myers patent. , to achieve the effect of increasing the diameter of the knurled portion of the handlebar, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

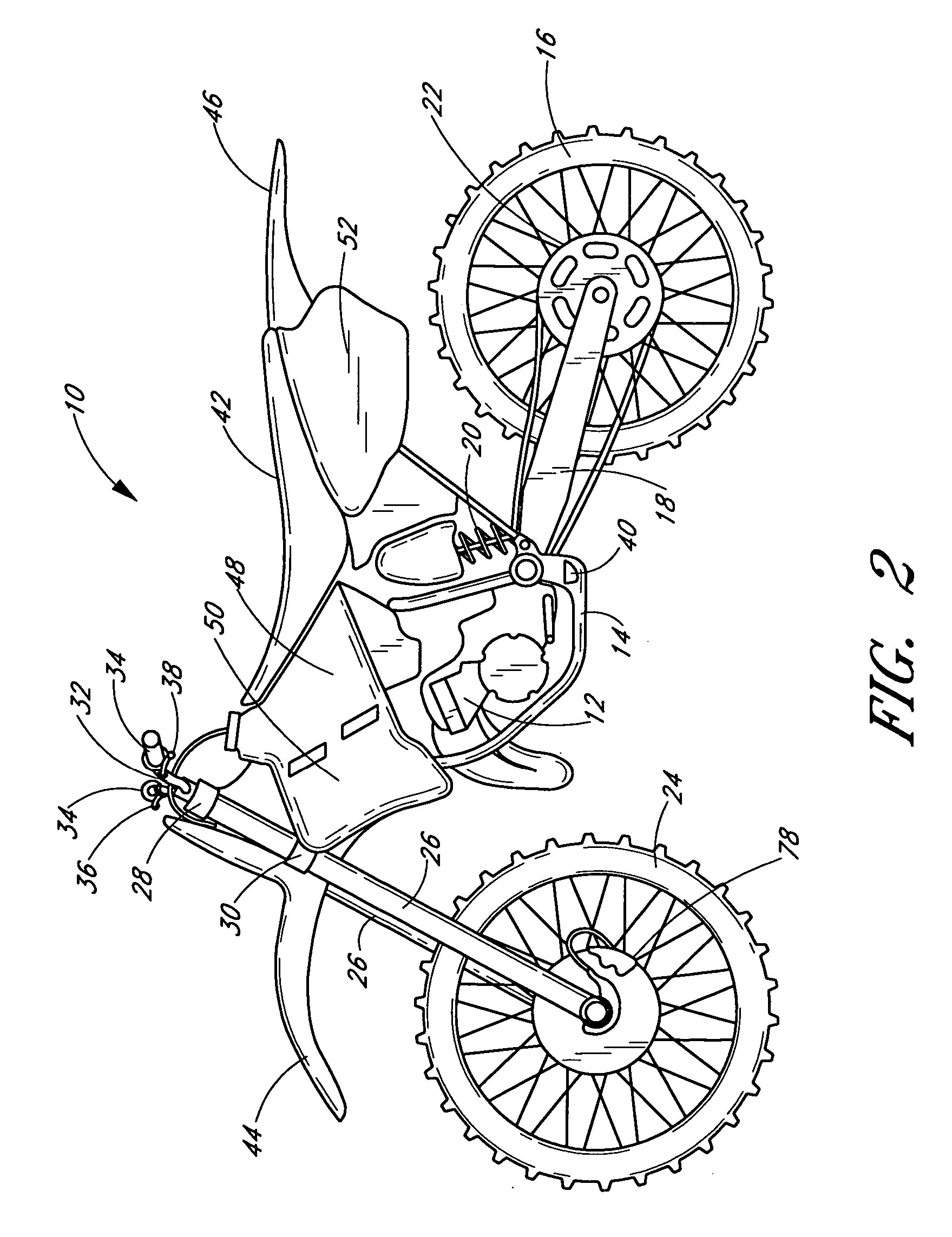

[0025] The present invention finds utility with a number of vehicles, including, without limitation, motorcycles, bicycles, all terrain vehicles (ATVs) and other types of vehicles where control levers may be employed. In addition, advantages present in preferred embodiments may be realized with a number of different control lever functions, such as for use with a manual clutch or braking system, for example. Illustrated embodiments of the control lever mounts, however, are particularly suited for use with a cable-actuated manual clutch lever of an off-road motorcycle.

[0026] With reference to FIG. 2, an off-road motorcycle, generally referred to by the reference numeral 10, is shown. Preferably, an internal combustion engine 12 and associated transmission is mounted within a frame 14 of the motorcycle 10. A rear wheel 16 is connected to the frame through a rear suspension system comprised of a swing arm 18 and a rear shock absorber 20. Preferably, the rear wheel is driven by the eng...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap