Variable roller blind structure

a roller blind and variable technology, applied in the direction of curtain suspension devices, sliding/moving grilles, door/window protection devices, etc., can solve the problems of inability to variably operate the blind body, limited practical use, and monotonous conventional roller blinds, etc., to achieve efficient boosting the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

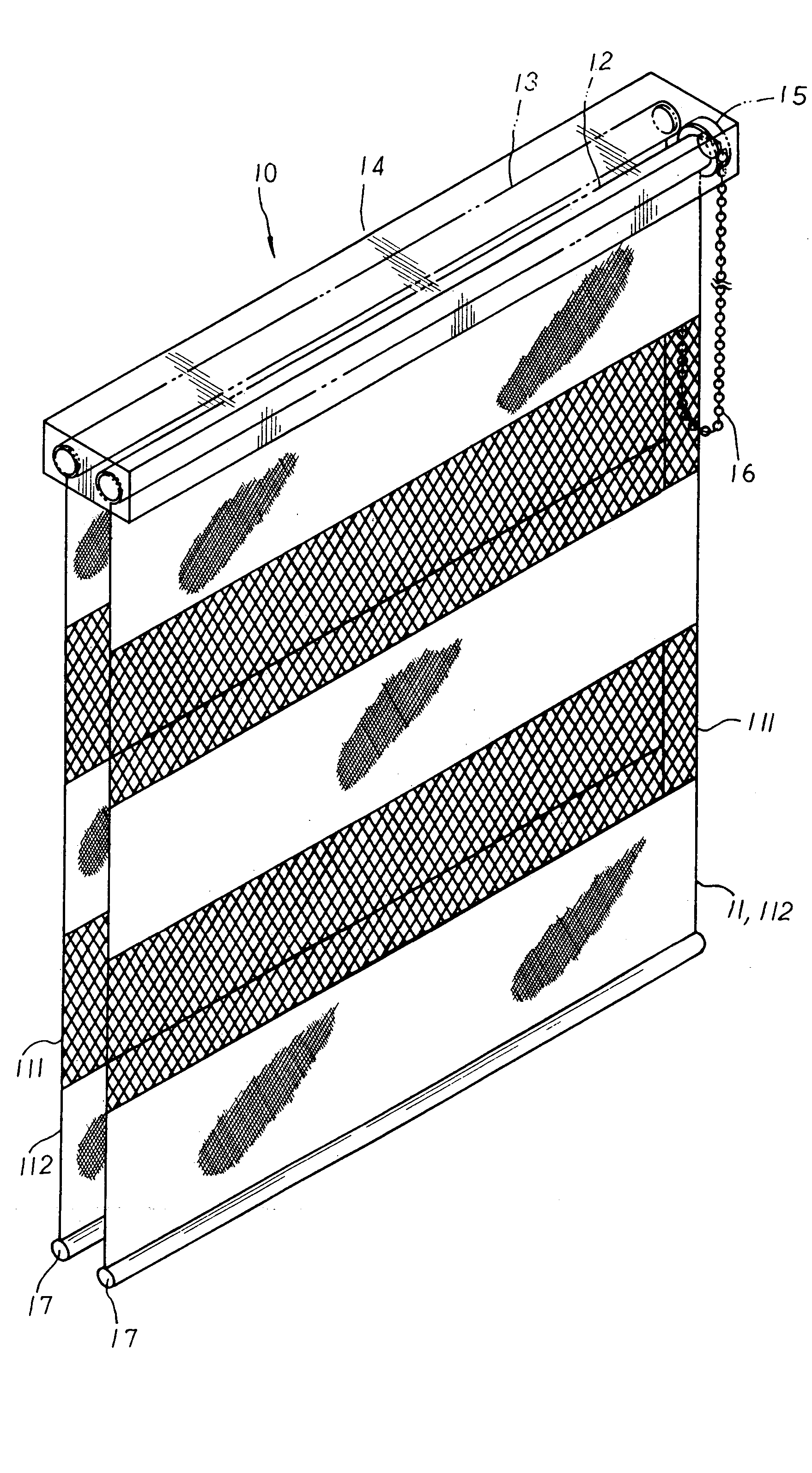

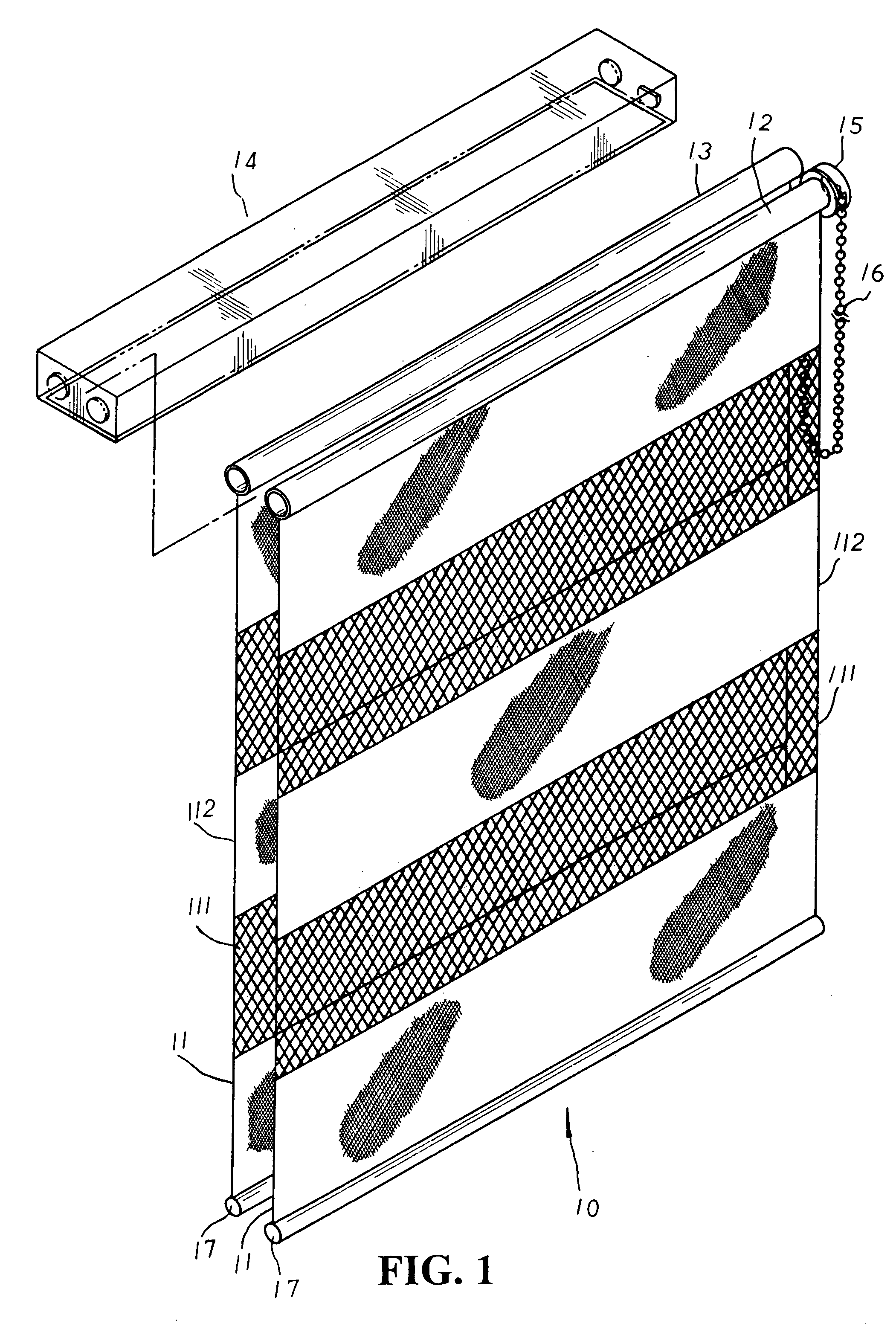

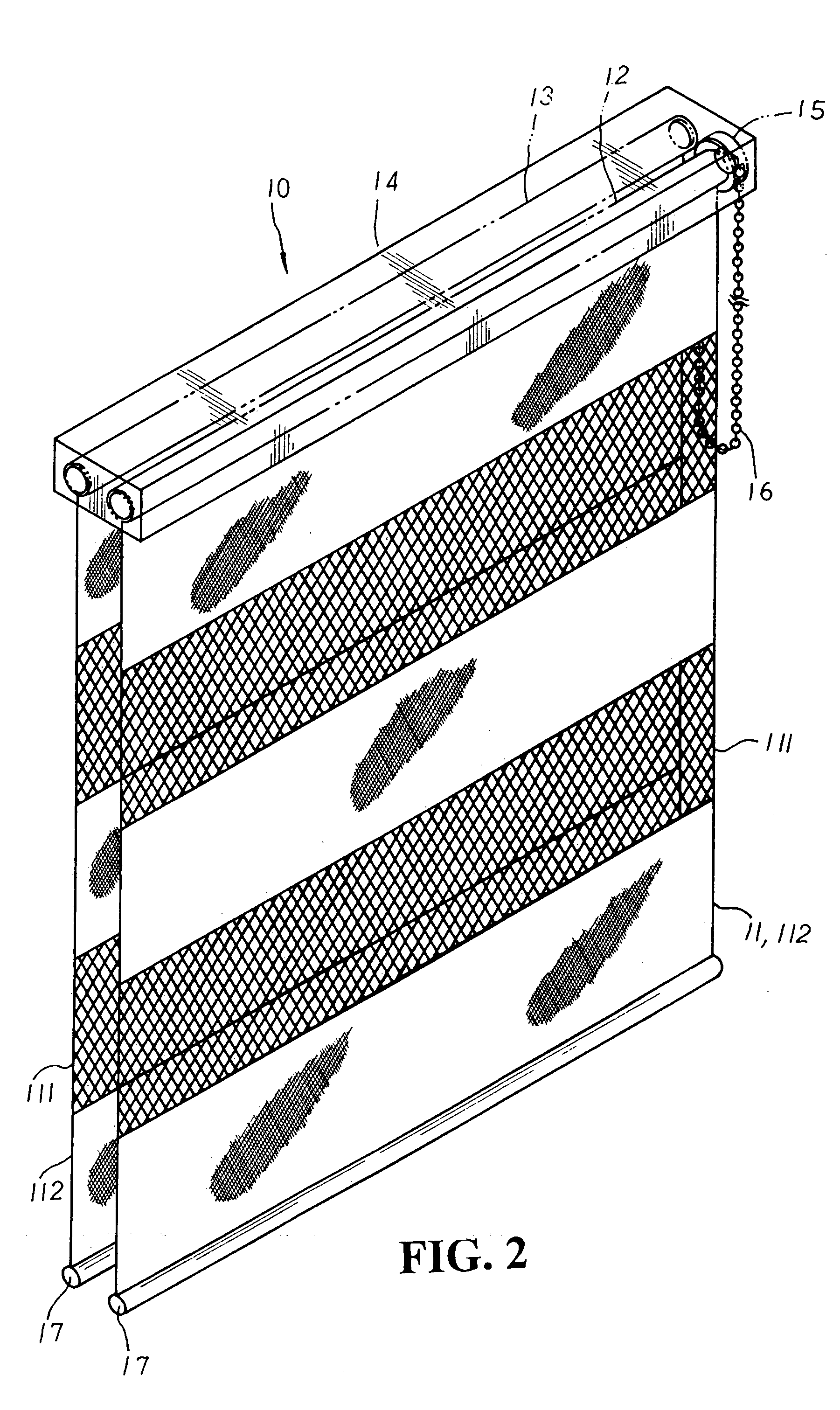

[0015] Please refer to FIGS. 1 to 3 inclusive. The present invention is related to a variable roller blind structure, including a roller blind 10 made up of more than one blind bodies 11 each equipped with a plurality of light-passable areas 111 alternatively arranged with a plurality of black-out areas 112 disposed at the surface thereon. The light-passable areas 111 of the blind body 11 can be made in net-like or porous shape, and the height of each black-out area 11.2 is slightly higher than that of the light-passable areas 111 thereof. At the top edge of the blind bodies 11 are respectively attached a rotatable roller shaft 12 and a stable roller shaft 13 that are juxtaposed at an interval and mounted at the inner side of an upper beam 14 therein. A manual-operated winding unit 15 or an automatic winding unit 15′ with a spring element 151′ attached thereto as shown in FIG. 3 is mutually engaged with the rotatable roller shaft 12 thereof to be actuated by an operating member 16 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com