Metal wood golf club striking plate with anisotropic materials and magnetic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

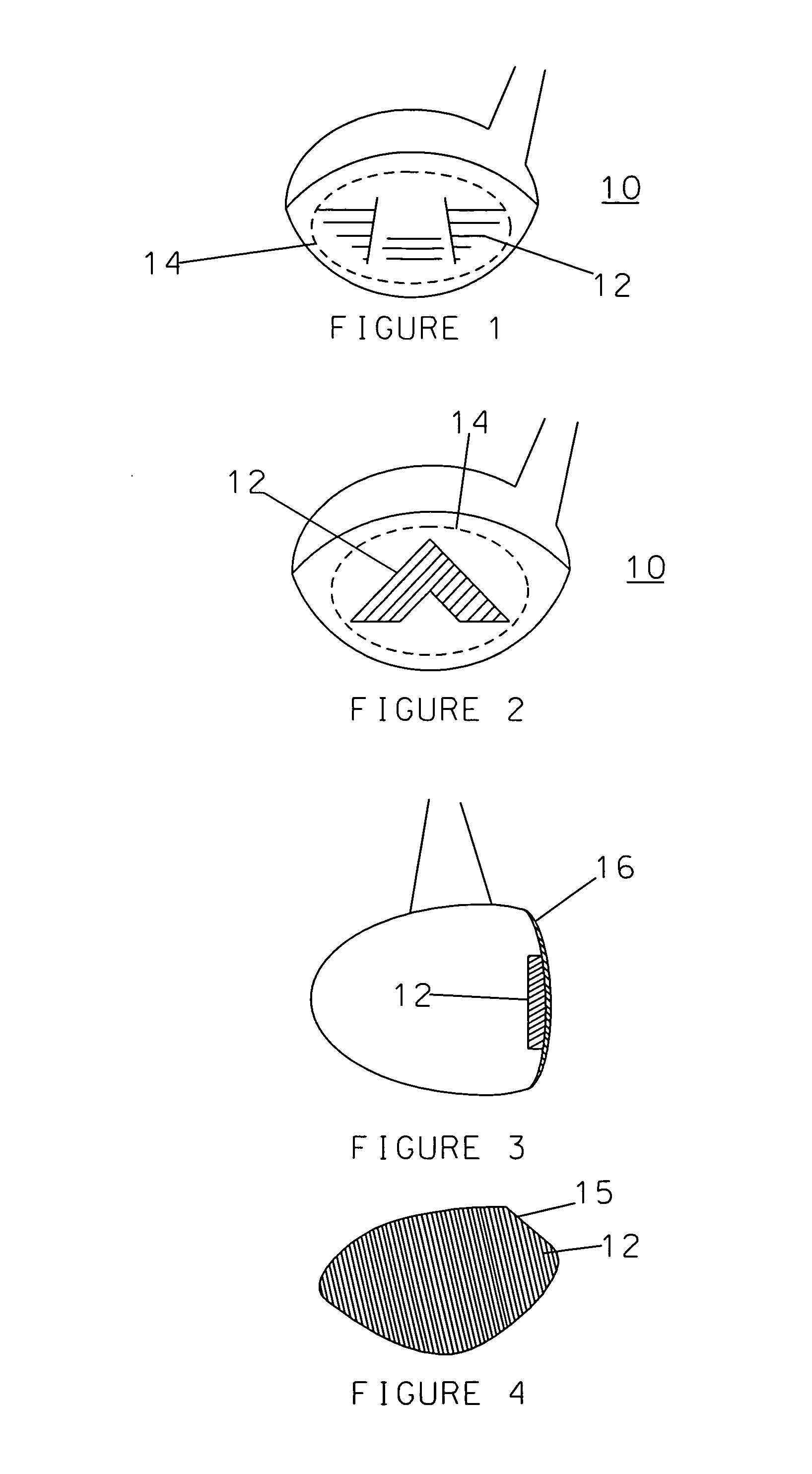

[0026] The present invention is described with reference to the enclosed detailed embodiment, wherein the same numbers are used. In particular, the present invention is directed to improved metal wood clubs which incorporate a composite, reinforced build up of an anisotropic fiber material such as graphite.

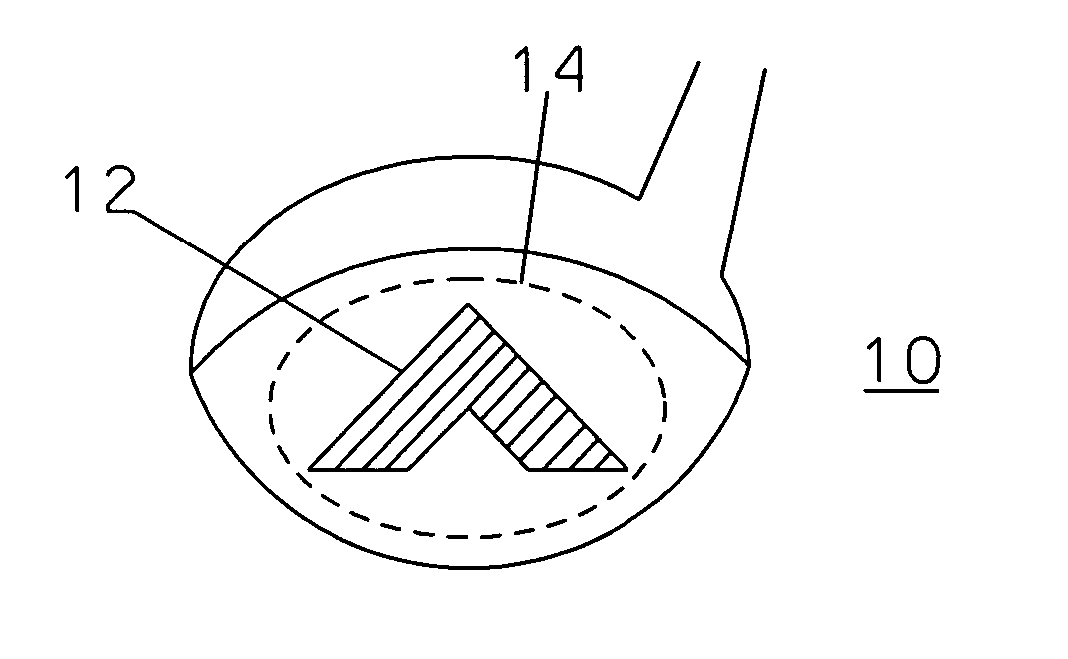

[0027] Referring to FIG. 1, the present invention comprises a hybrid golf club face 10 comprising an anisotropic material such as fiber and graphite 12 affixed as an insert in the resin. The fibers and graphite are affixed to the inside club face 16.

[0028] The graphite crystal is one of the most anisotropic (meaning exhibiting properties with different values when measured along axes in different directions) bodies known. Anisotropy is the direct result of the layered structure with extremely strong carbon-carbon bonds in the basal plane. Properties of graphite crystals illustrating this anisotropy are shown in Table 1. Of particular interest for the electronics cooling market i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com