Prefabricated universal structural steel panel and panel system

a technology of structural steel and prefabricated steel, applied in the field of prefabricated steel panels, can solve the problems of increasing cost and labor savings, and the panel is limited to a fixed range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

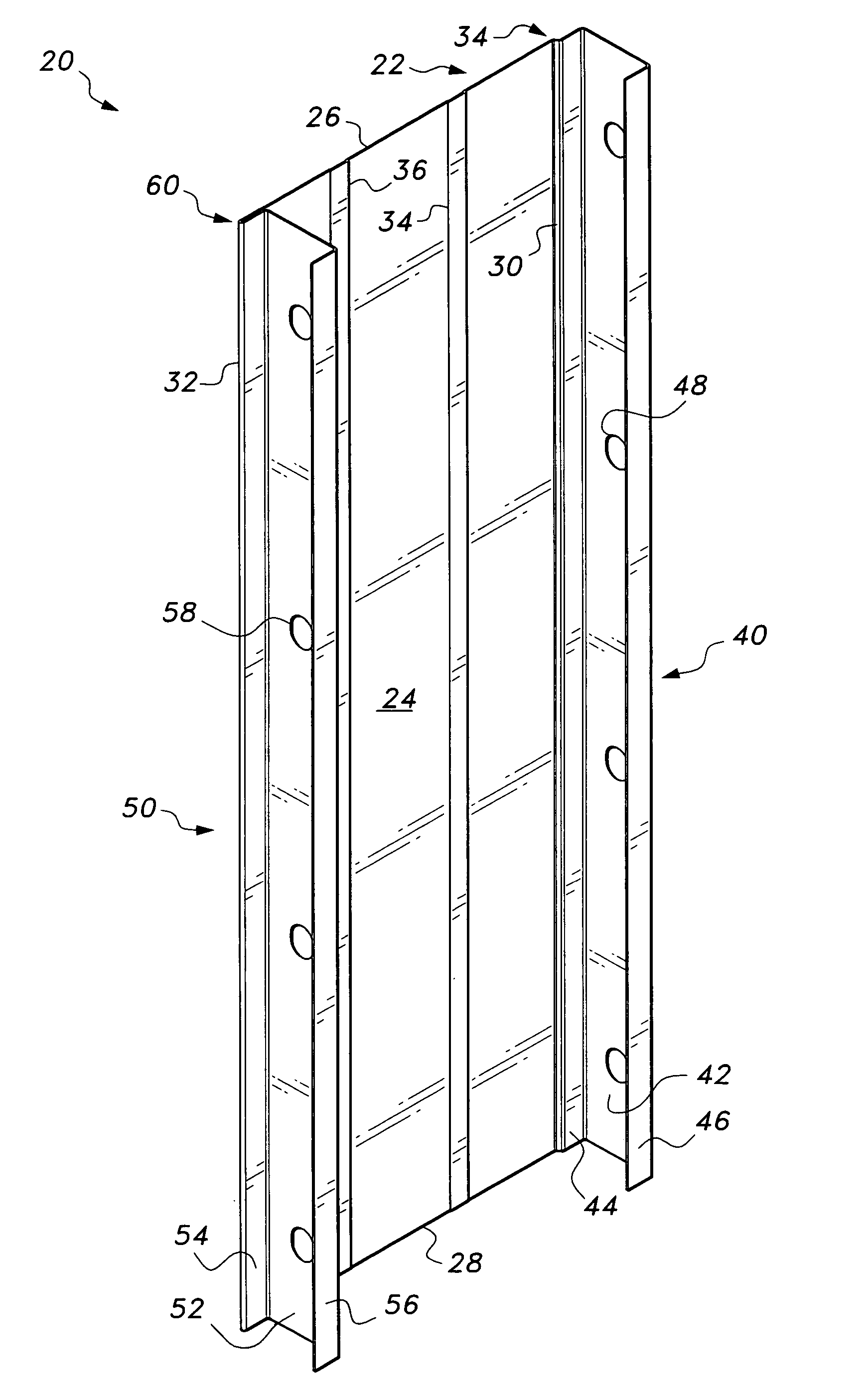

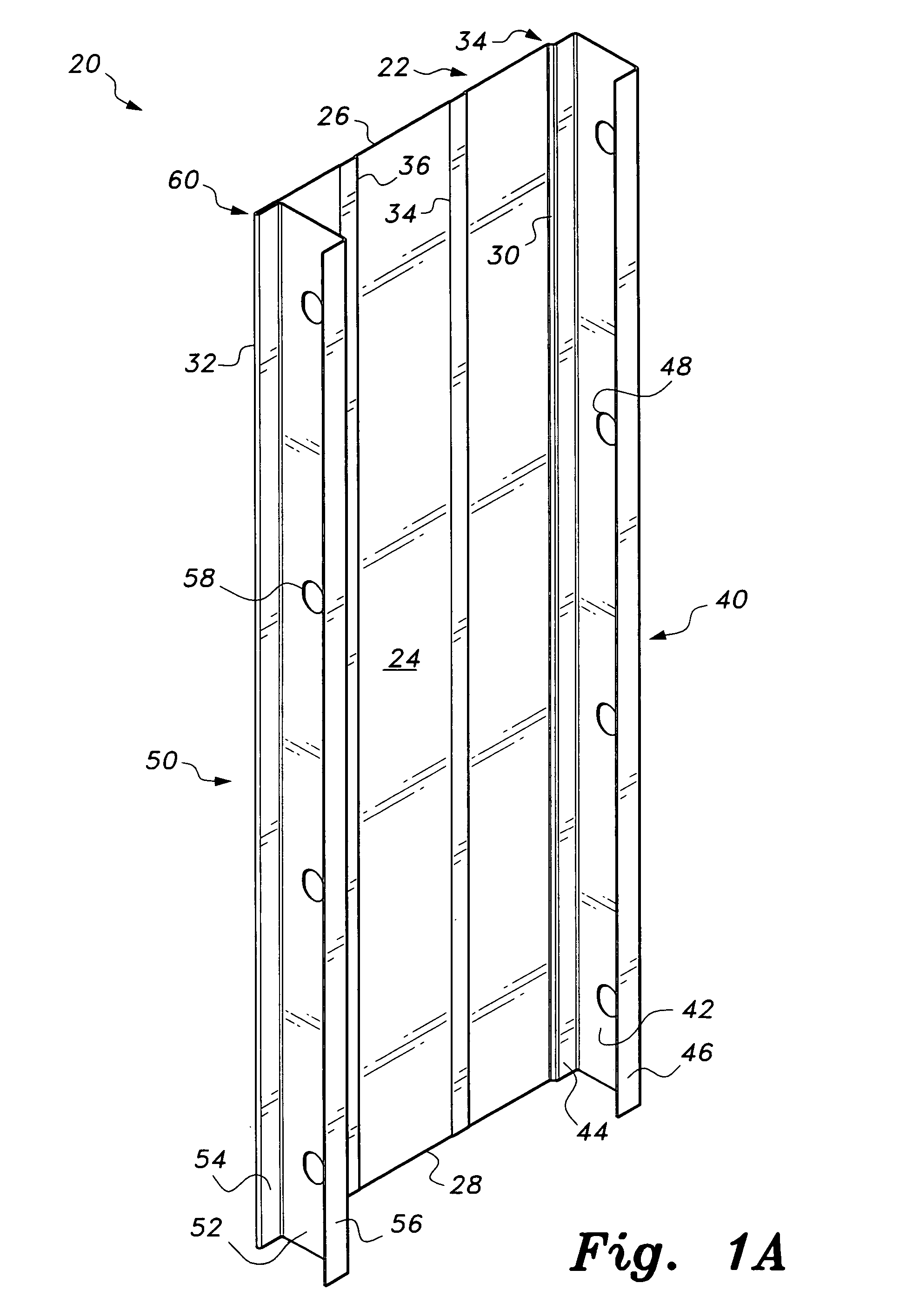

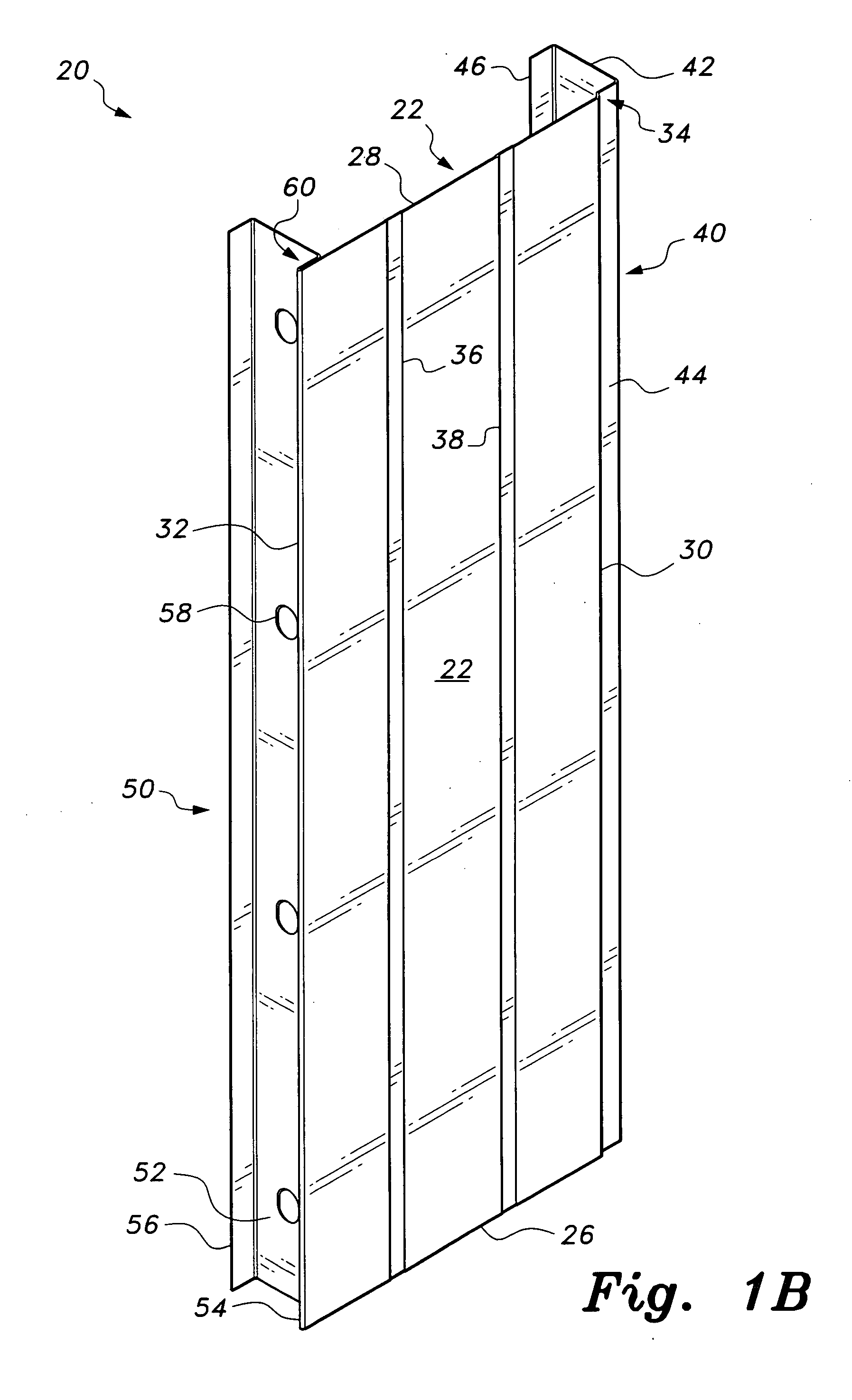

[0027] Turning to the drawings, FIGS. 1A, 1B, 1C, and 2, show a preferred embodiment of a prefabricated universal structural steel panel 20, in accordance with the present invention. Generally, the universal structural steel panel 20 includes a generally elongated rectangular panel having an opposed exterior and interior surfaces 22, 24, an opposed first and second end portions 26, 28, and an opposed first and second side edge portions 30, 32. The first side edge portion 30 is designed and configured with a beveled or tapered side edge portion 34. In addition, the panel 20 includes stiffening ribs 34 and 36, which are integrally formed and embedded to the panel 20 and extend longitudinally from first and second end portions 26, 28. Although the preferred embodiment of the panel 20 is substantially rectangular shape, the panel 20 can be fabricated in a variety of different shapes. For example, the panel 20 can be a substantially square, oblong or trapezoidal shape.

[0028] An elongate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com