Heat exchanger with increased heat transfer efficiency and a low-cost method of forming the heat exchanger

a heat exchanger and heat transfer efficiency technology, applied in the field of heat exchangers, can solve the problems of reducing the useful life of the equipment inside the cabinet, generating more heat than basic pots cards, and damage to equipment, and achieve the effect of less manufacturing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

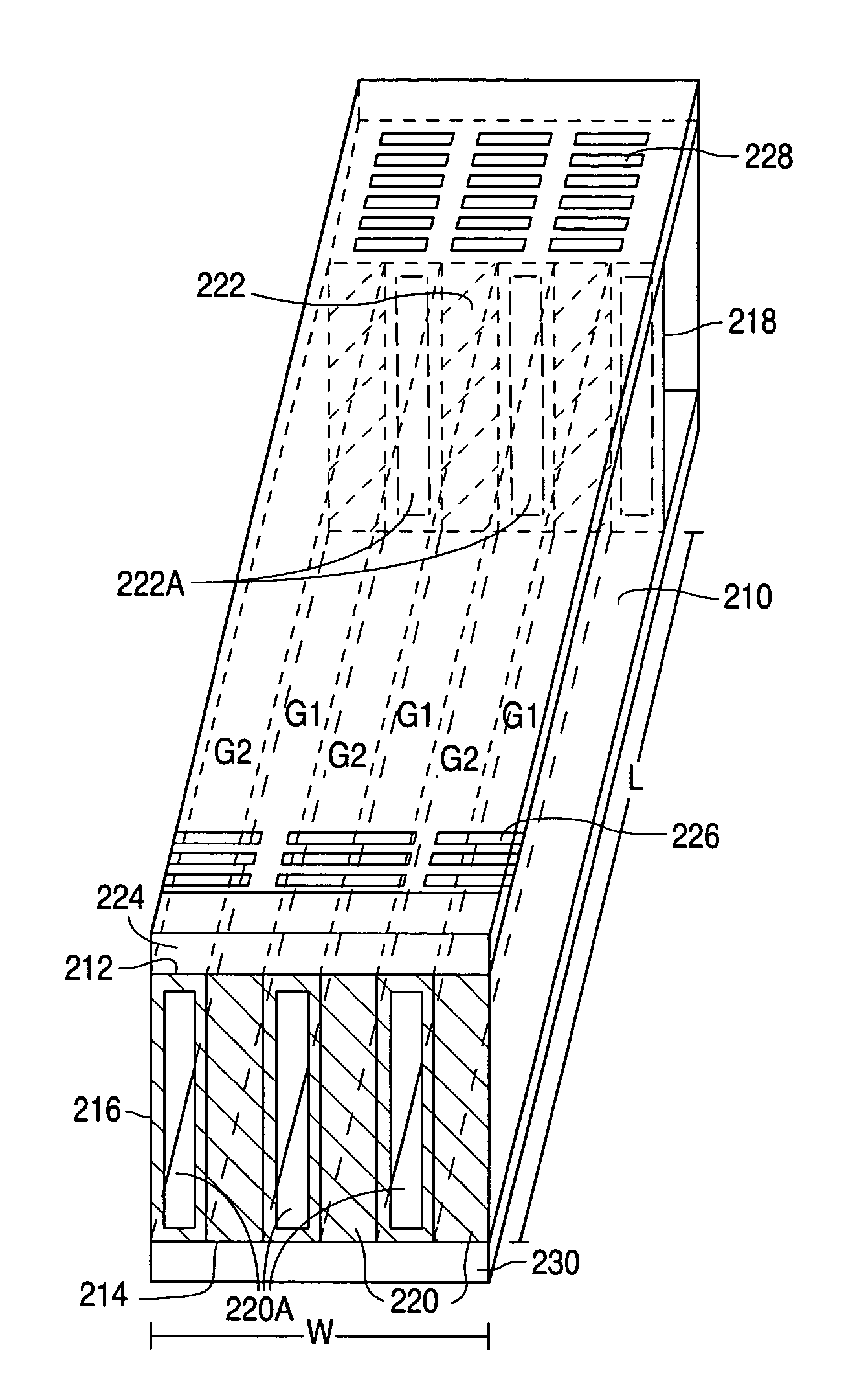

[0031]FIGS. 2A-2F show a series of views that illustrate an example of a heat exchanger 200 in accordance with the present invention. FIG. 2A shows a front side perspective view, while FIG. 2B shows a back side perspective view. FIG. 2C shows a top plan view taken between lines 2C1-2C1 and 2C2-2C2 of FIG. 2A, FIG. 2D shows a right side view taken along lines 2D-2D of FIG. 2C, and FIG. 2E shows a bottom plan view taken between lines 2E1-2E1 and 2E2-2E2 of FIG. 2B. FIG. 2F shows a perspective view of FIG. 2C taken along lines 2F-2F of FIG. 2C.

[0032] As shown in FIGS. 2A-2F, heat exchanger 200 includes an air flow structure 210 that directs the flow of external and internal air through heat exchanger 200. Air flow structure 210, in turn, has a top surface 212 and a bottom surface 214. In addition, structure 200 has a width W, a length L, a first edge 216 that runs along the width W, and a second edge 218 that runs along the width W.

[0033] Further, air flow structure 210 includes a nu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com