Customized footwear and process for manufacturing such footwear

a technology of custom footwear and manufacturing process, applied in the field of footwear, can solve the problems of affecting the performance of climbers, the pressure exerted by the footwear on the toes and heel, and the ball of the foot, and can be quite uncomfortable and sometimes painful, so as to improve the comfort of the wearer's feet and relieve the various pressure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

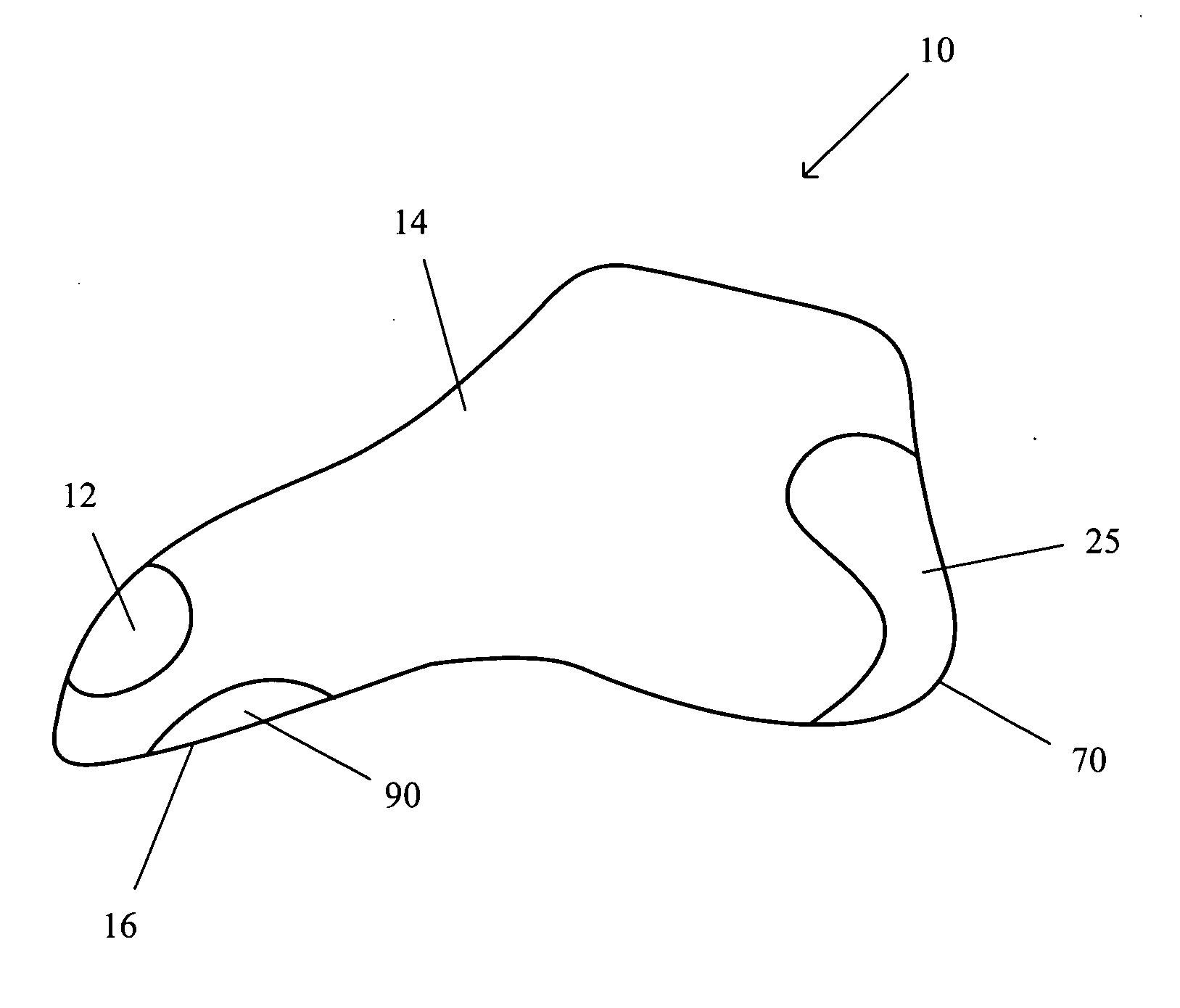

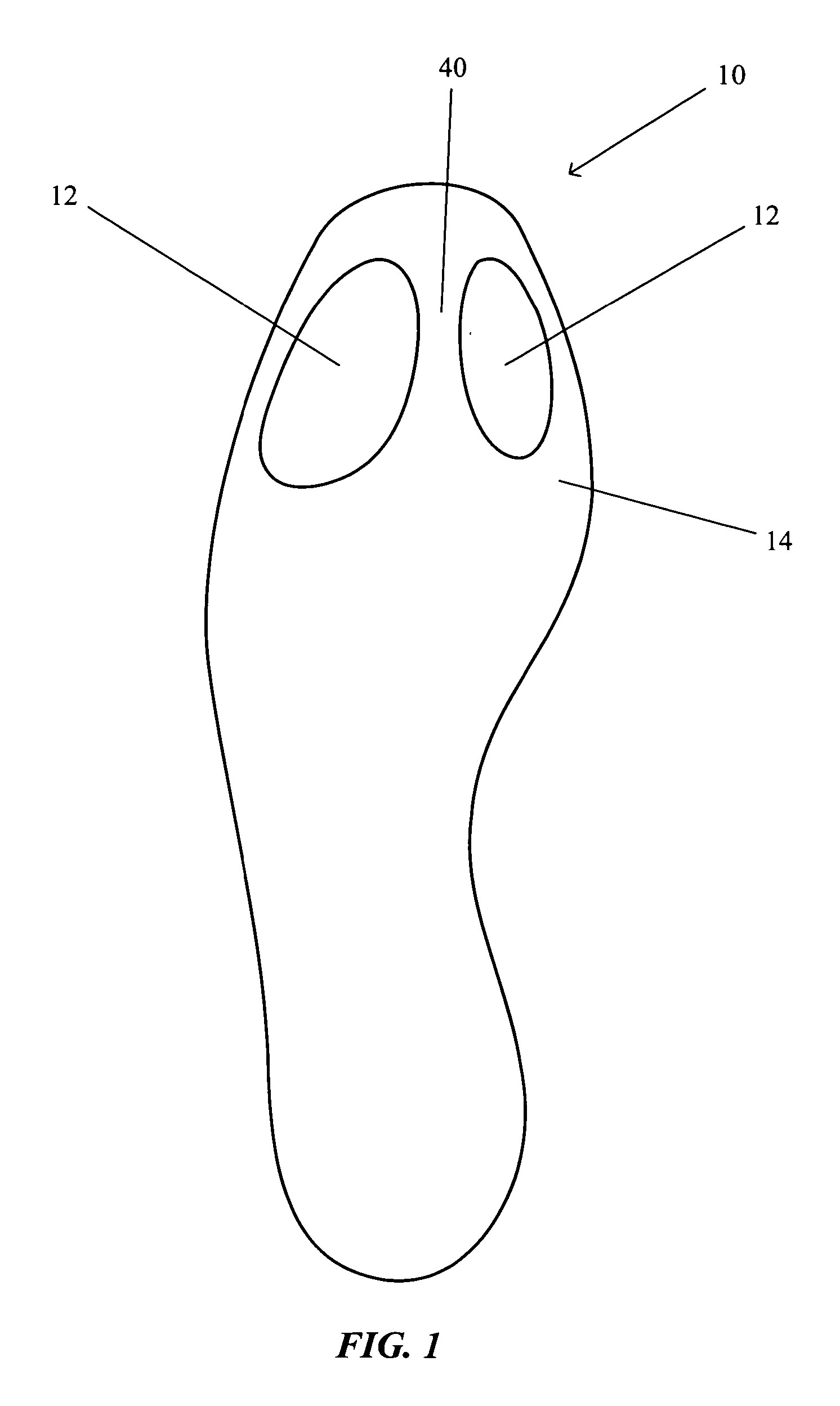

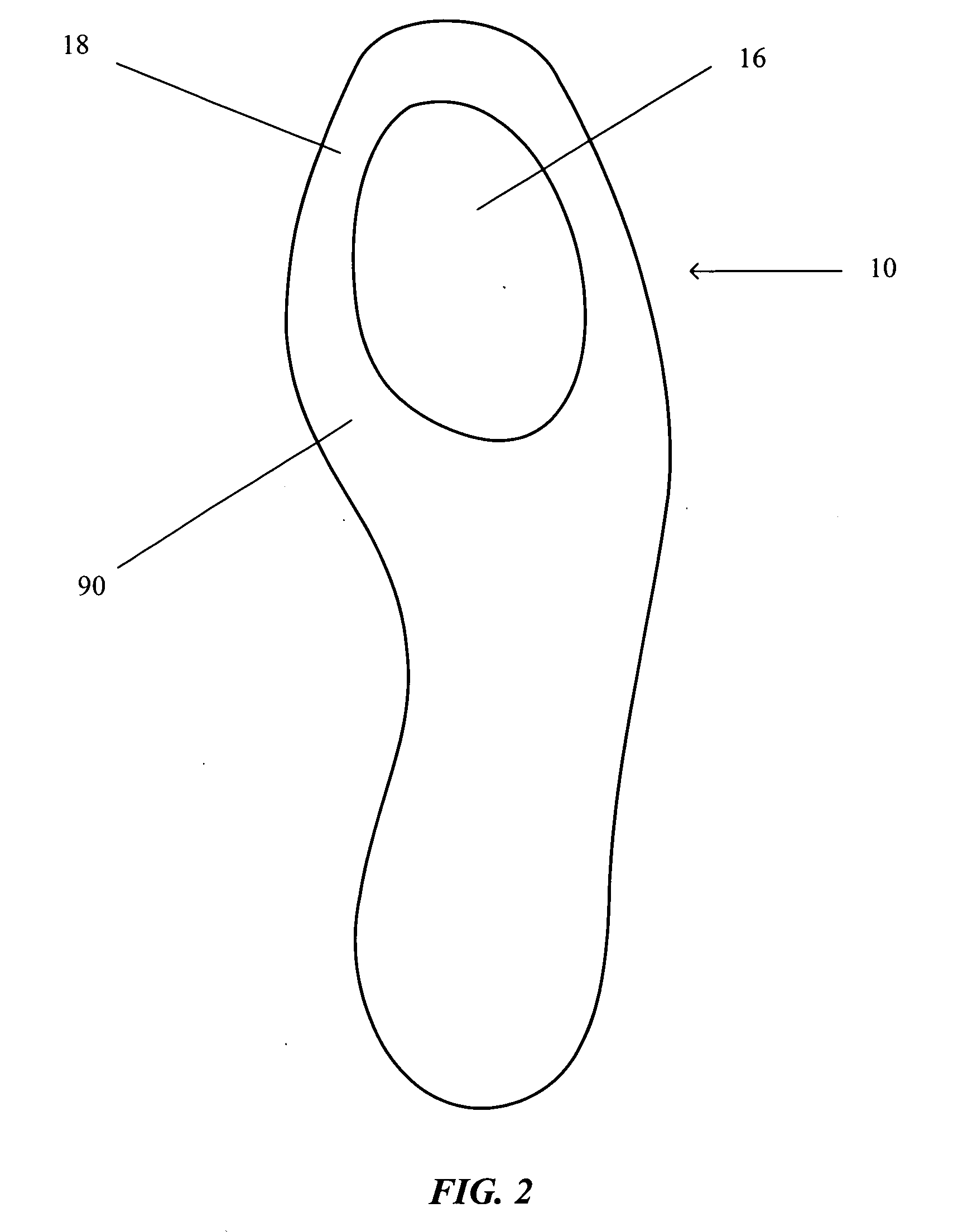

[0030] An article of footwear is provided having improved distribution of pressure on the top region of the toes, over the instep of the foot, on the upper region of the ankle, the back and lower region of the heel, and / or the region under the ball of the foot by custom molding the interior surface of the inventive footwear to the foot. This is accomplished by providing curved projecting volumes, or protrusions, on interior surfaces of the footwear in regions where the foot exerts high pressure against the interior surfaces of the footwear and / or in regions that match natural depressions or cavities in the foot, thereby producing footwear that provides better fit and more even distribution of pressure. More specifically, the protrusions, which are preferably formed of moldable foam pieces, are provided in at least one of the following regions: the upper toe region, the instep region, the upper ankle region, the back and lower region of the heel, and the region around the ball of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com