Tool box

a tool box and tool technology, applied in the field of tool boxes, can solve the problems of difficult uniform spacing and alignment of individual pegs during welding process, affecting and affecting the use of the tool box user. to achieve the effect of maximizing the storage capacity of the tool box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

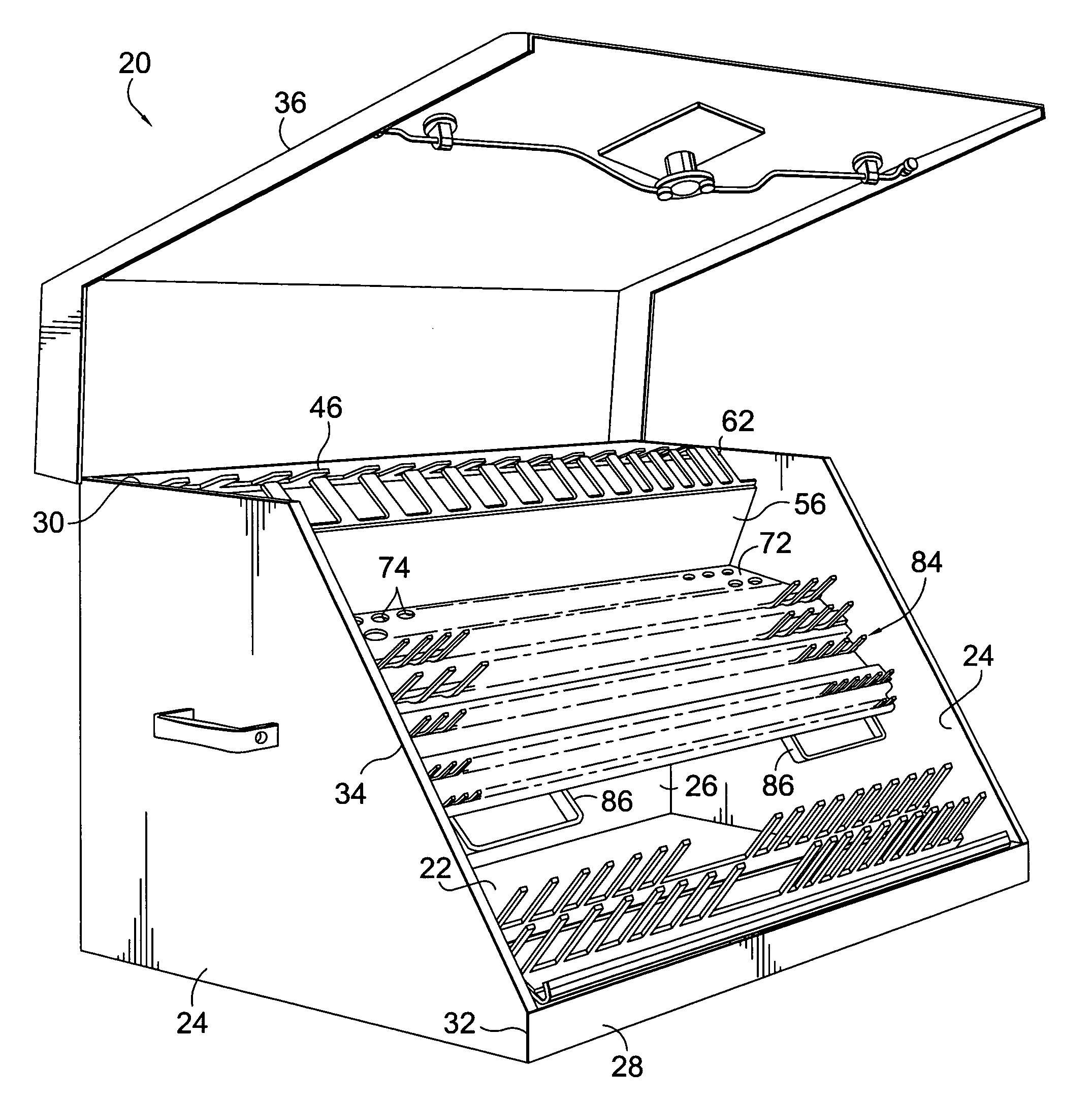

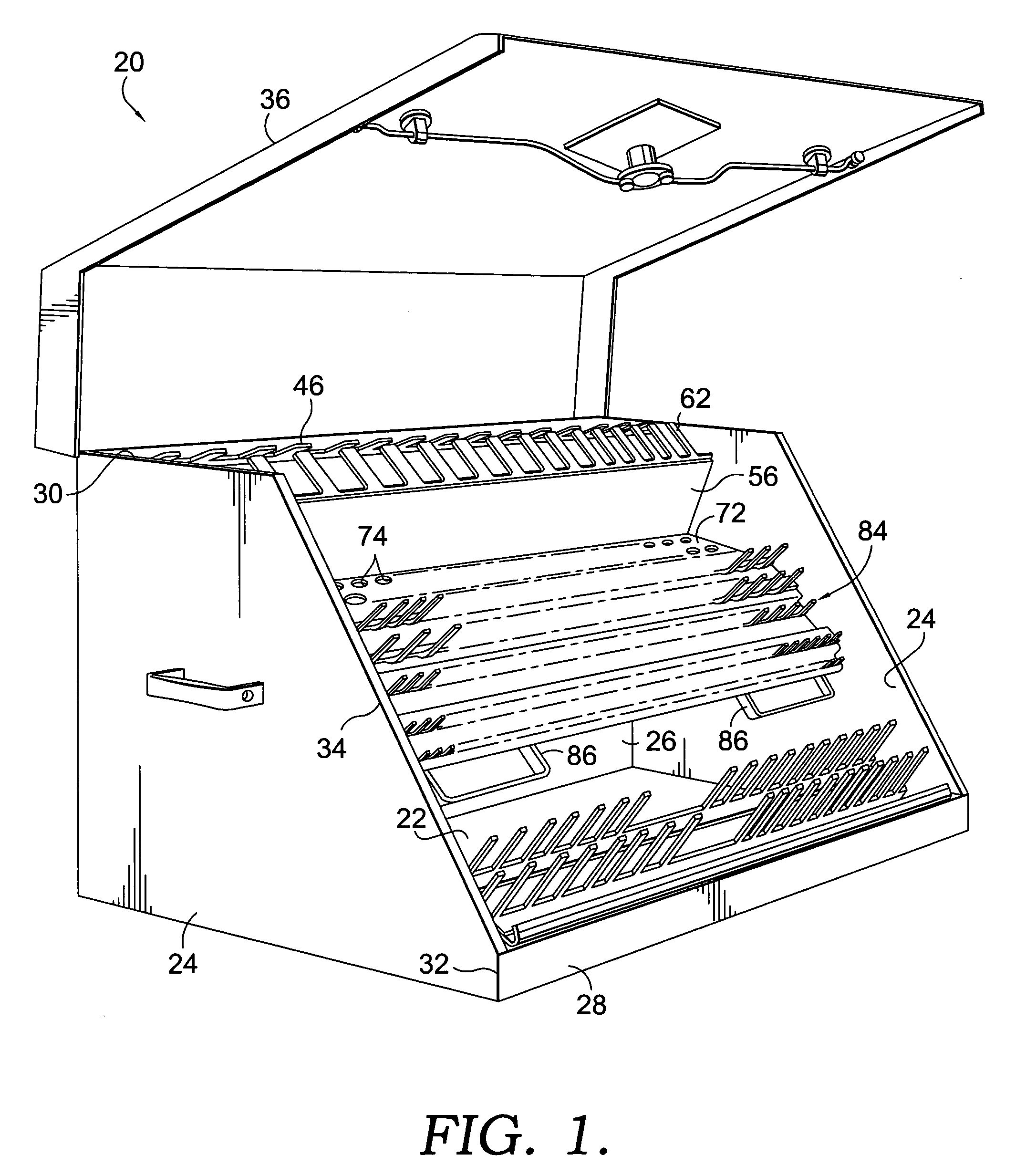

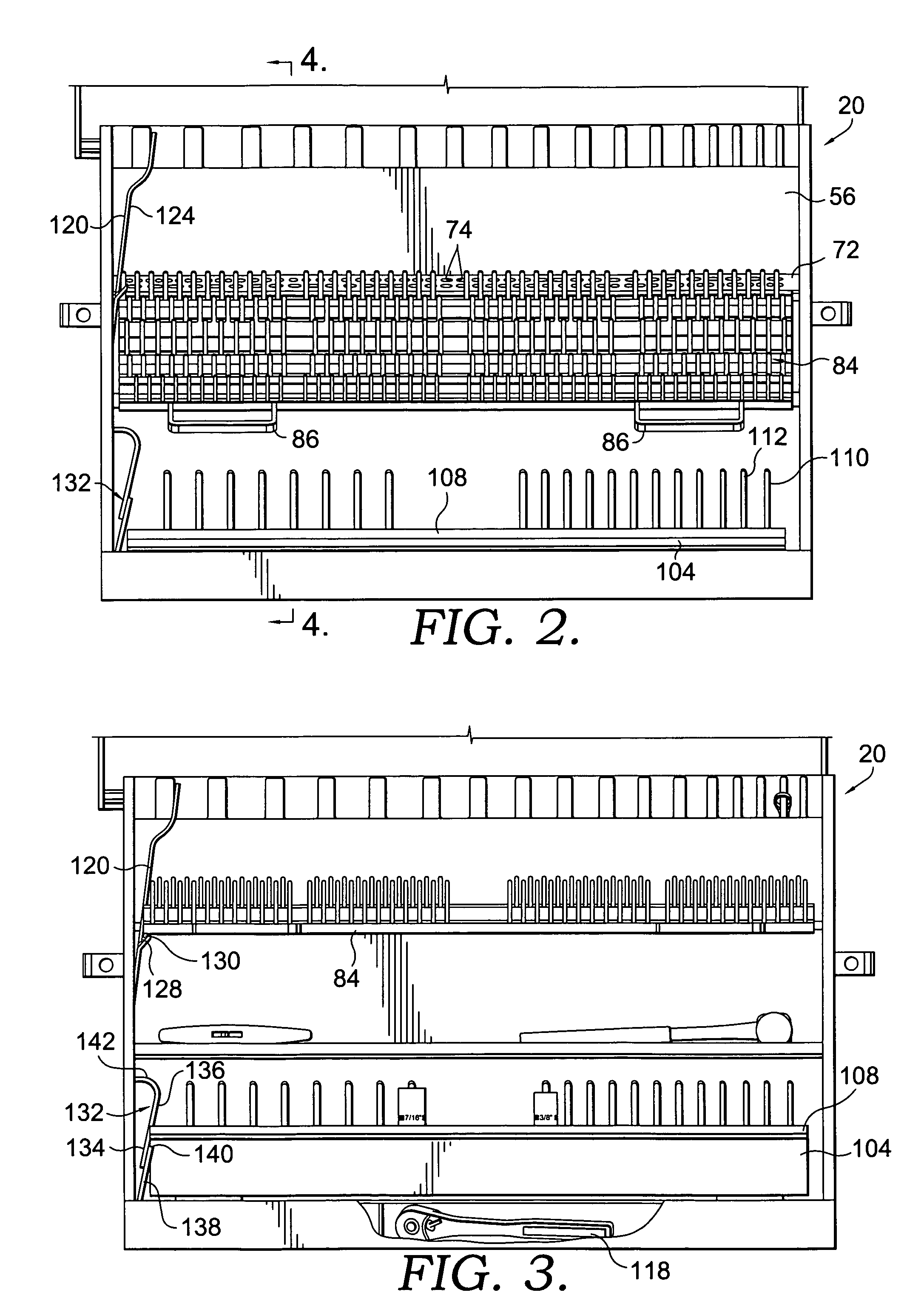

[0030] With reference to FIGS. 1 and 4, tool box 20 constructed in accordance with the present invention is shown. Tool box 20 has a bottom portion 22, a pair of side portions 24 extending upwardly from bottom portion 22, a back portion 26 extending upwardly from bottom portion 22, and a front portion 28 extending upwardly from bottom portion 22. Side portions 24 each have an upper horizontal edge 30 and a front vertical edge 32. Upper edge 30 and front edge 32 are connected by a downwardly sloping slanted edge 34. Thus, bottom portion 22, side portions 24, back portion 26, and front portion 28 define an expanse in which tools or other items can be stored.

[0031] With additional reference to FIG. 7, a cover 36 is attached to back portion 26 at a location near upper edge 38 of back portion 26. Cover 36 is attached to back portion 26 by a hinge structure 40 such that cover 36 is rotatable between an open position, illustrated in FIG. 1, and a closed position, illustrated in FIG. 7. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com