Vacuum cleaner with cyclonic separating dirt cup and dirt cup door

a vacuum cleaner and cyclonic technology, applied in the field of vacuum cleaners, can solve the problems of clogging of debris, small filter elements, and suffering of above-mentioned hand-held vacuum cleaners, and achieve the effects of reducing the number of clogged debris, reducing the efficiency of cleaning, and improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

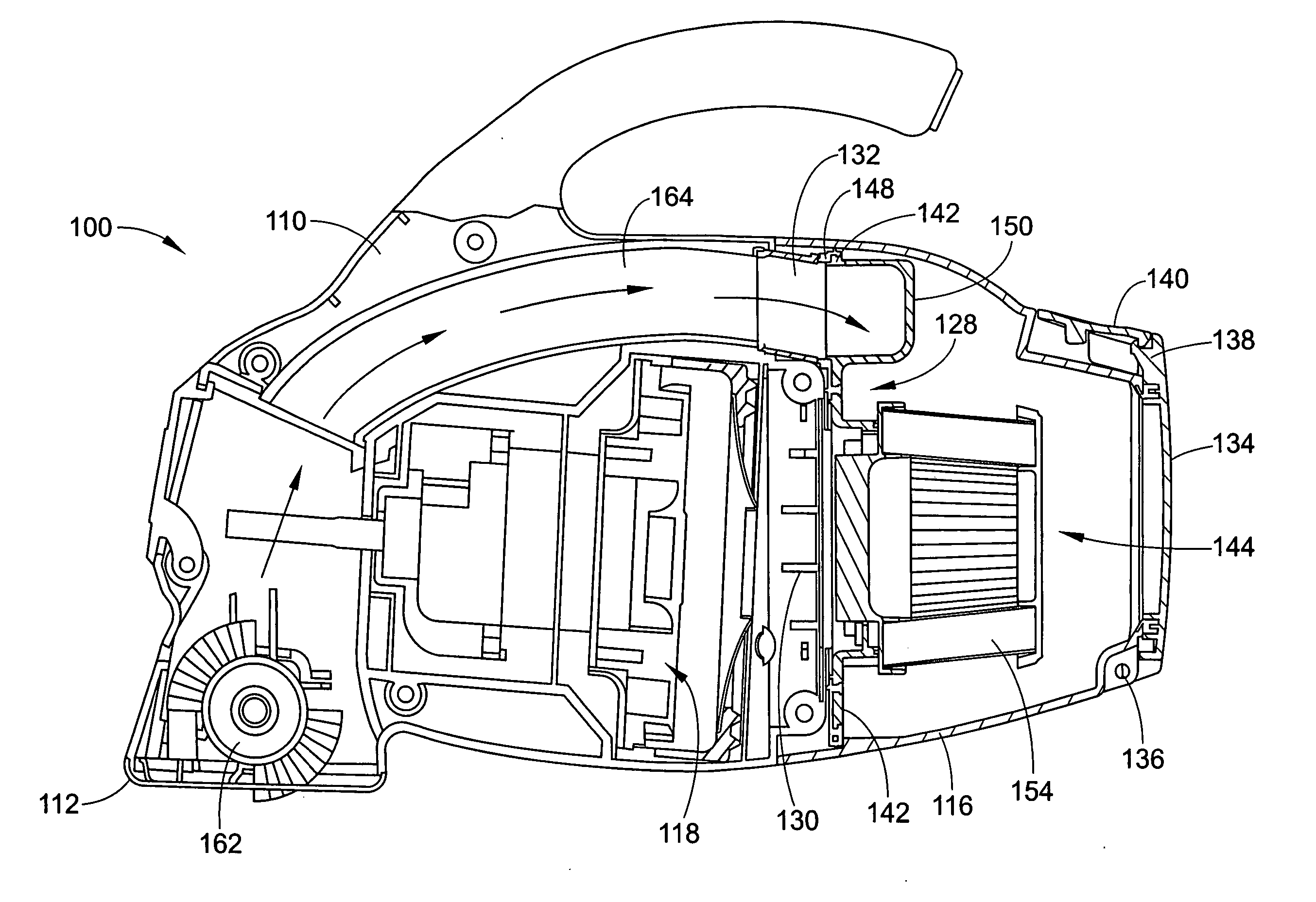

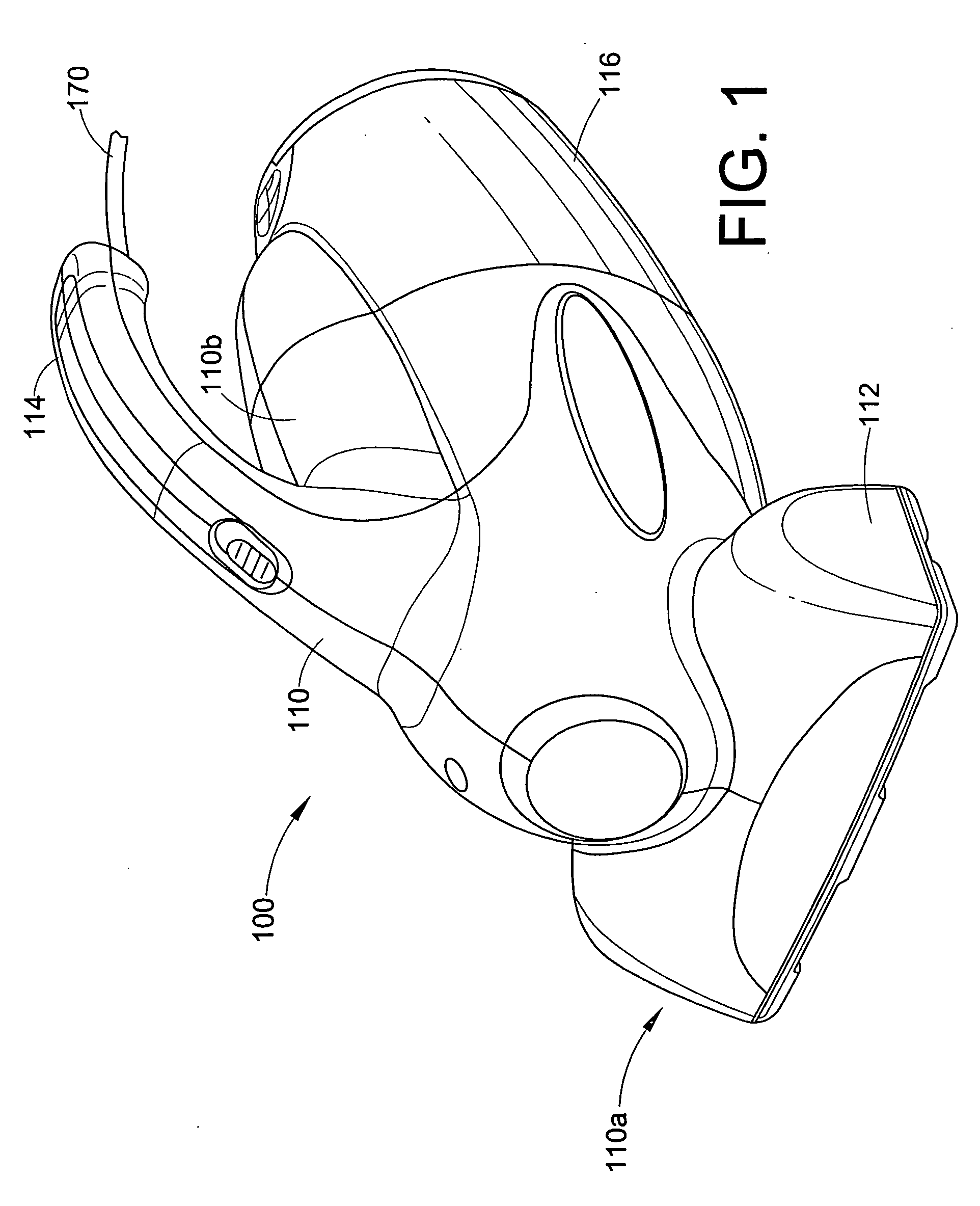

[0024] With reference to FIG. 1, a first embodiment of a hand-held vacuum cleaner 100 is shown. The hand-held vacuum cleaner 100 generally includes a housing 110, a suction nozzle 112, a handle 114, a dirt cup 116 and a suction fan and motor assembly 118 (FIG. 8). As shown in FIG. 1, the housing 110 can be formed of two bilaterally symmetrical pieces, a left half portion and a right half portion. Of course, other housing constructions are also contemplated. As can be seen in FIG. 9, the suction fan and motor assembly 118 is disposed internally to the housing 110. The suction nozzle 112 can be disposed adjacent a first end 110a of the housing 110, whereas the dirt cup 116 can be disposed adjacent a second end 110b of the housing 110.

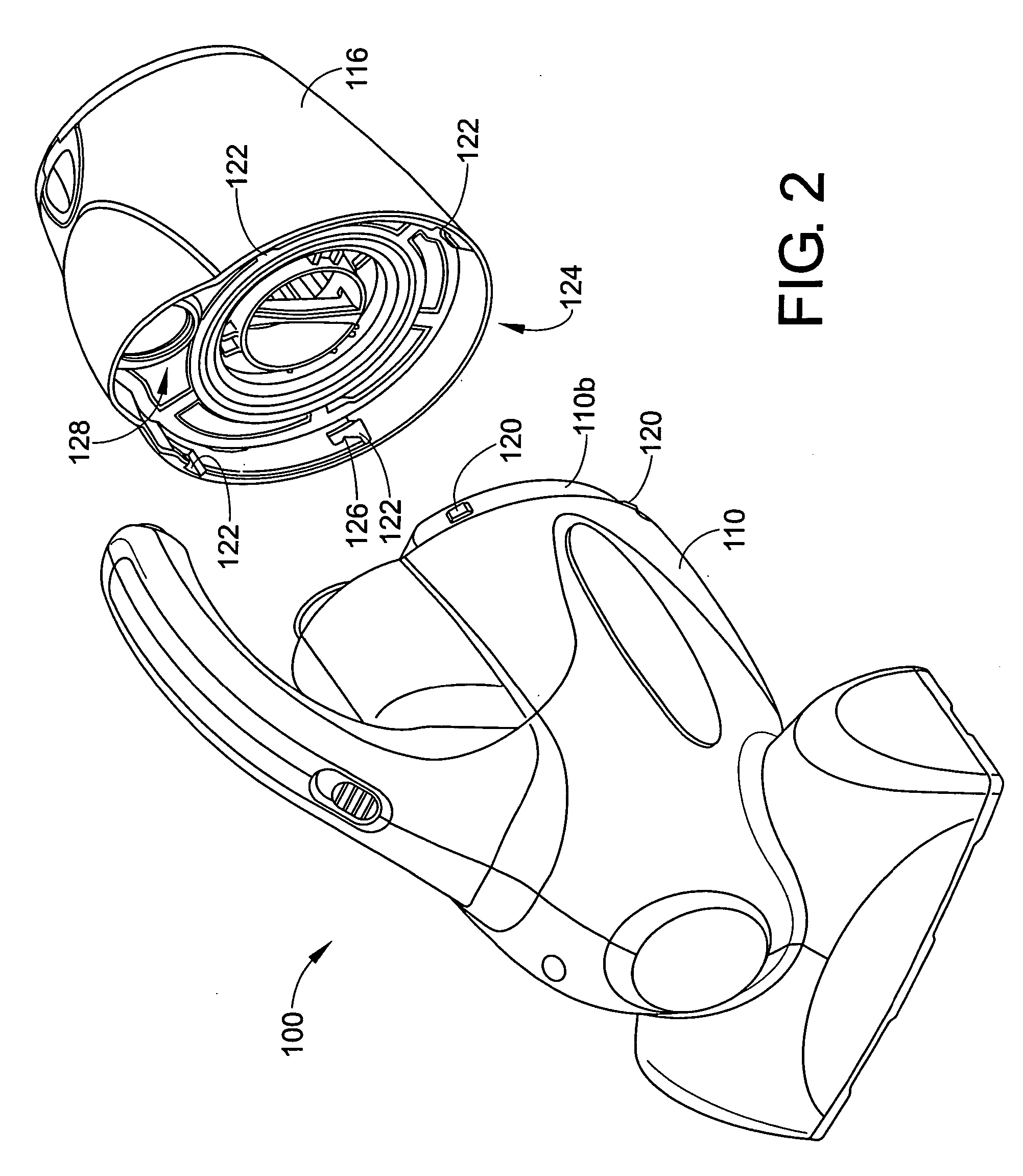

[0025] Now with reference to FIG. 2, a perspective view of the first embodiment 100 of the hand-held vacuum cleaner is shown with the dirt cup 116 removed from the housing 110. A plurality of nubs 120 are disposed along the second end 110b of the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com