Flame simulating assembly including an air filter

a technology of simulating assembly and air filter, which is applied in the direction of combustion process, combustion ignition, heating fuel, etc., can solve the problem of least partial obstruction of air filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

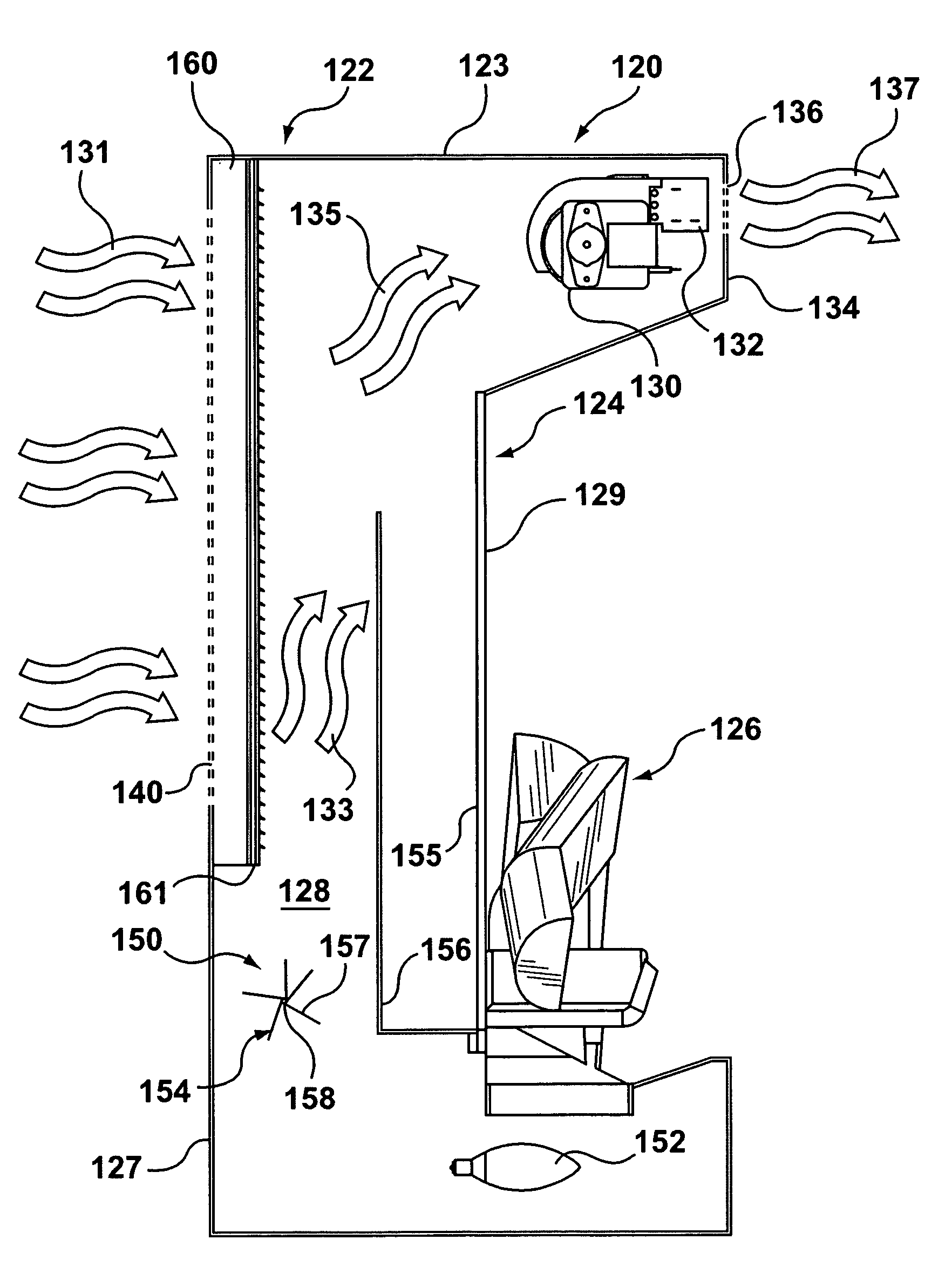

[0039] Reference is first made to FIGS. 3-5 to describe a preferred embodiment of a flame simulating assembly in accordance with the invention indicated generally by the numeral 120. The flame simulating assembly 120 preferably includes a housing 122 with a top panel 123, two or more side panels 125 supporting the top panel 123, a back panel 127 connecting the side panels 125, and one or more front panels 134 positioned substantially opposite to the back panel 127. As can be seen in FIGS. 3 and 4, the flame simulating assembly also includes a simulated fuel bed 126 disposed in the housing 122 and a screen 124 positioned behind the simulated fuel bed 126, and the screen 124 has a front surface 129 disposed adjacent to the simulated fuel bed. The flame simulating assembly 120 additionally includes a flame image subassembly 150 for providing images of flames on the front surface 129 of the screen 124, as will be described. As can be seen in FIG. 3, the screen 124, the housing 122 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com