Coreless winding apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

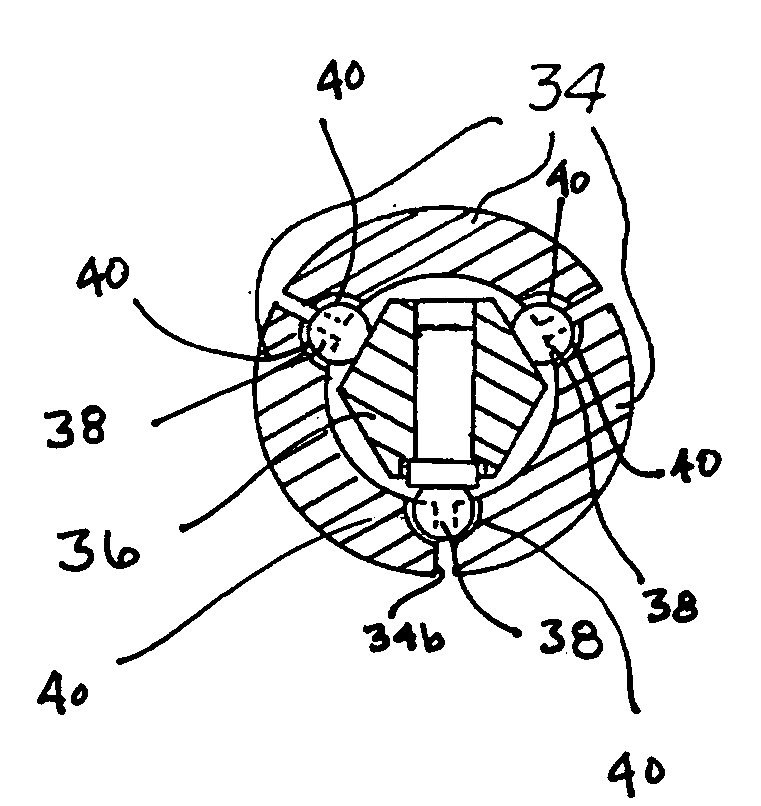

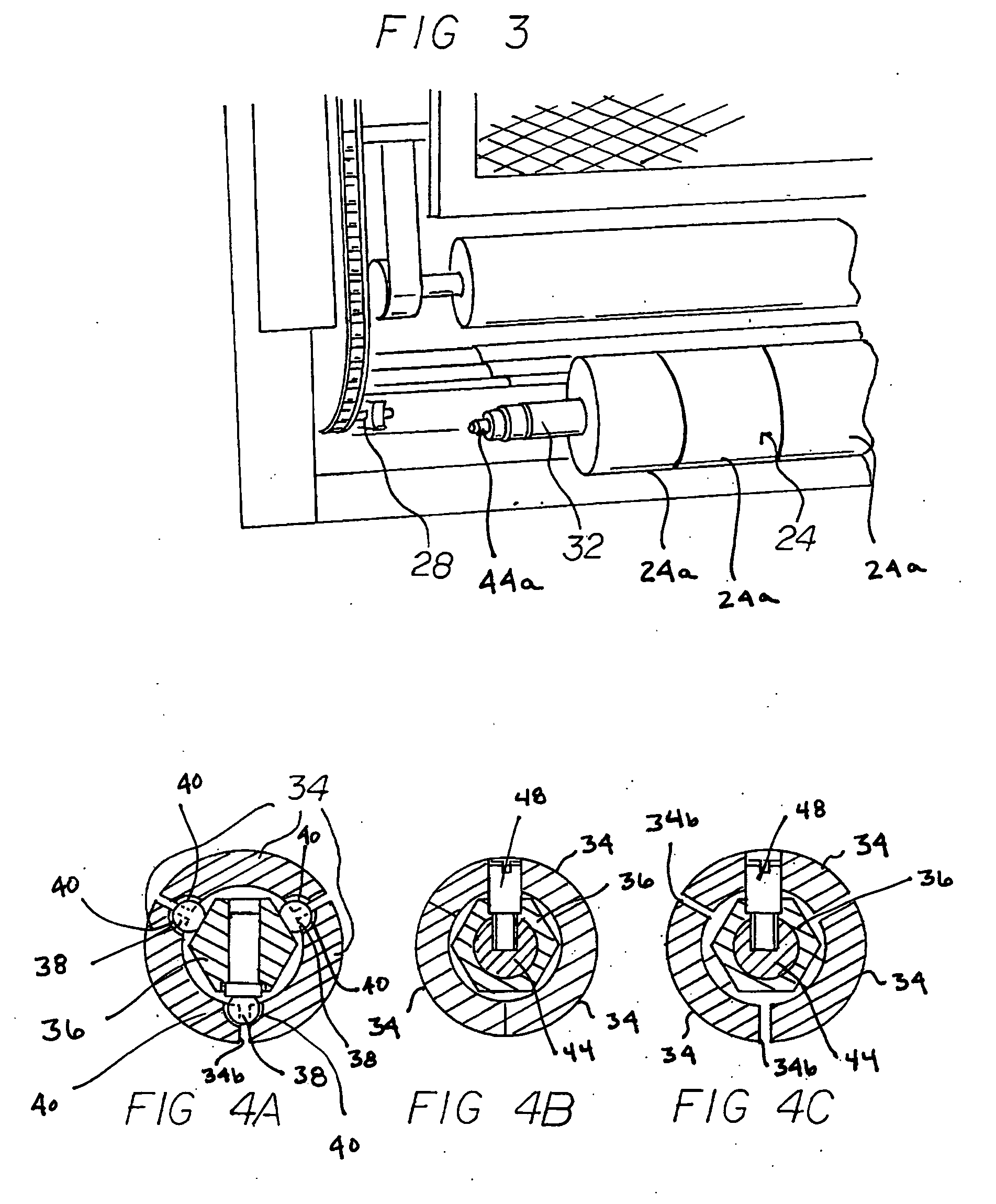

[0024] The present invention relates to an apparatus for forming coreless paper rolls. The apparatus includes an expansible mandrel that can be used in conjunction with an existing rewinder. The mandrel is segmented, with the segments expanding when the mandrel is loaded into the rewinder. While in the rewinder, a web of material, such as the type used to form register receipt rolls, is wound upon the mandrel. After a sufficient amount of material has been taken up, the mandrel can be removed. Upon removal, the segments of the mandrel contract, whereby the cross section of the mandrel is reduced and the roll can be removed. The result is a coreless roll of material.

Rewinder Apparatus

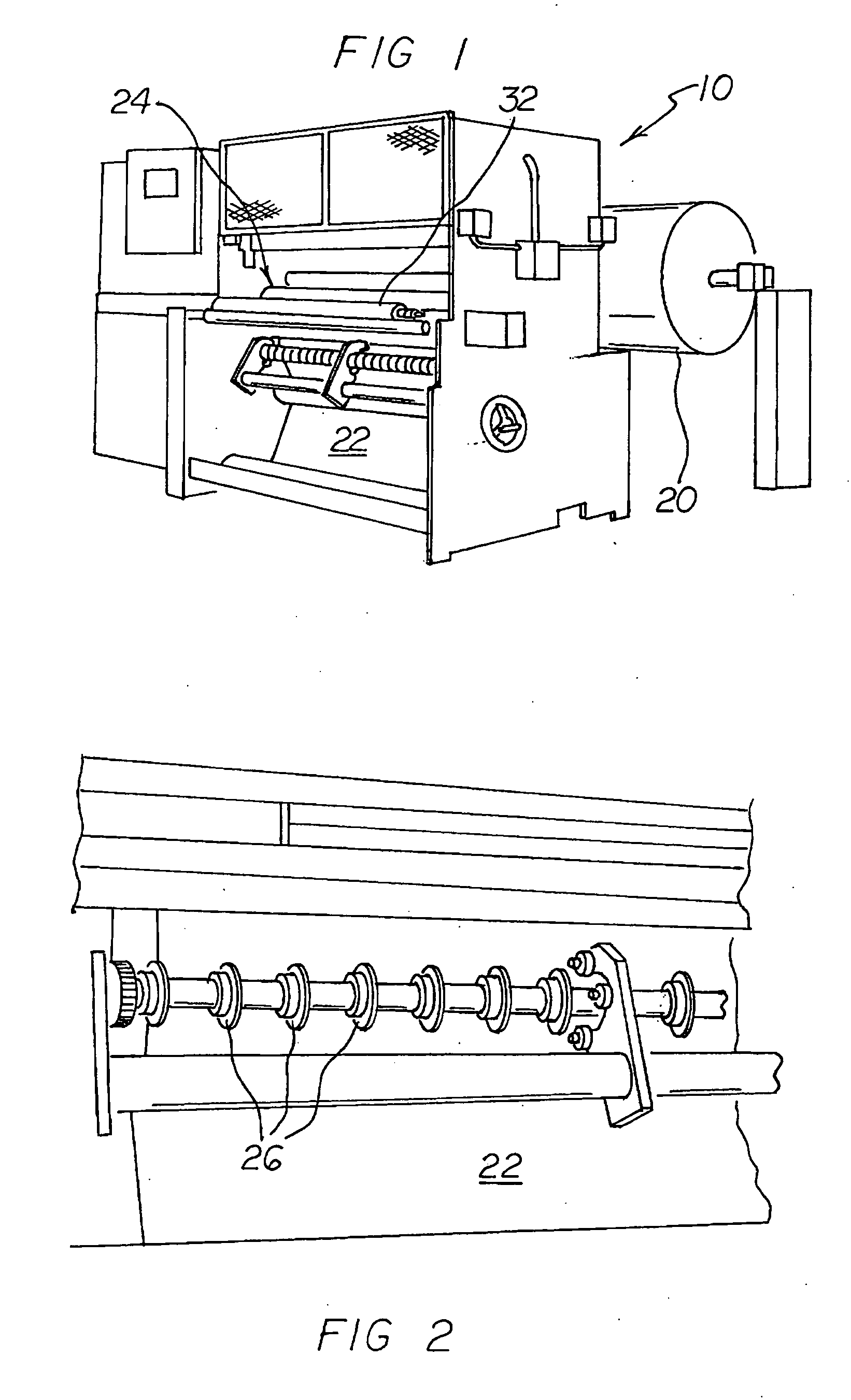

[0025]FIG. 1 illustrates a rewinder 10 that can be used in conjunction with the mandrel of the present invention. More specifically, the depicted rewinder is a surface winder sold by Dusenbery Worldwide. As is known in the art, such rewinders include a supply roll 20 from which a web of material 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com