Milking Parlor for the Forward Straight Line Animal Ambulation and Individual Presentation of an Animal to be Milked in a Milking Stall Located Intermediate a Holding Area and a Release Area

a technology of straight line animal ambulation and milking parlor, which is applied in the direction of milking devices, milking animals, fettering apparatus, etc., can solve the problems of pipeline system inducing significant operator fatigue, milking units being kicked off or stepped, and little to protect the operator from being kicked or stepped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present milking parlor provides for individual sequencing of animals to be milked.

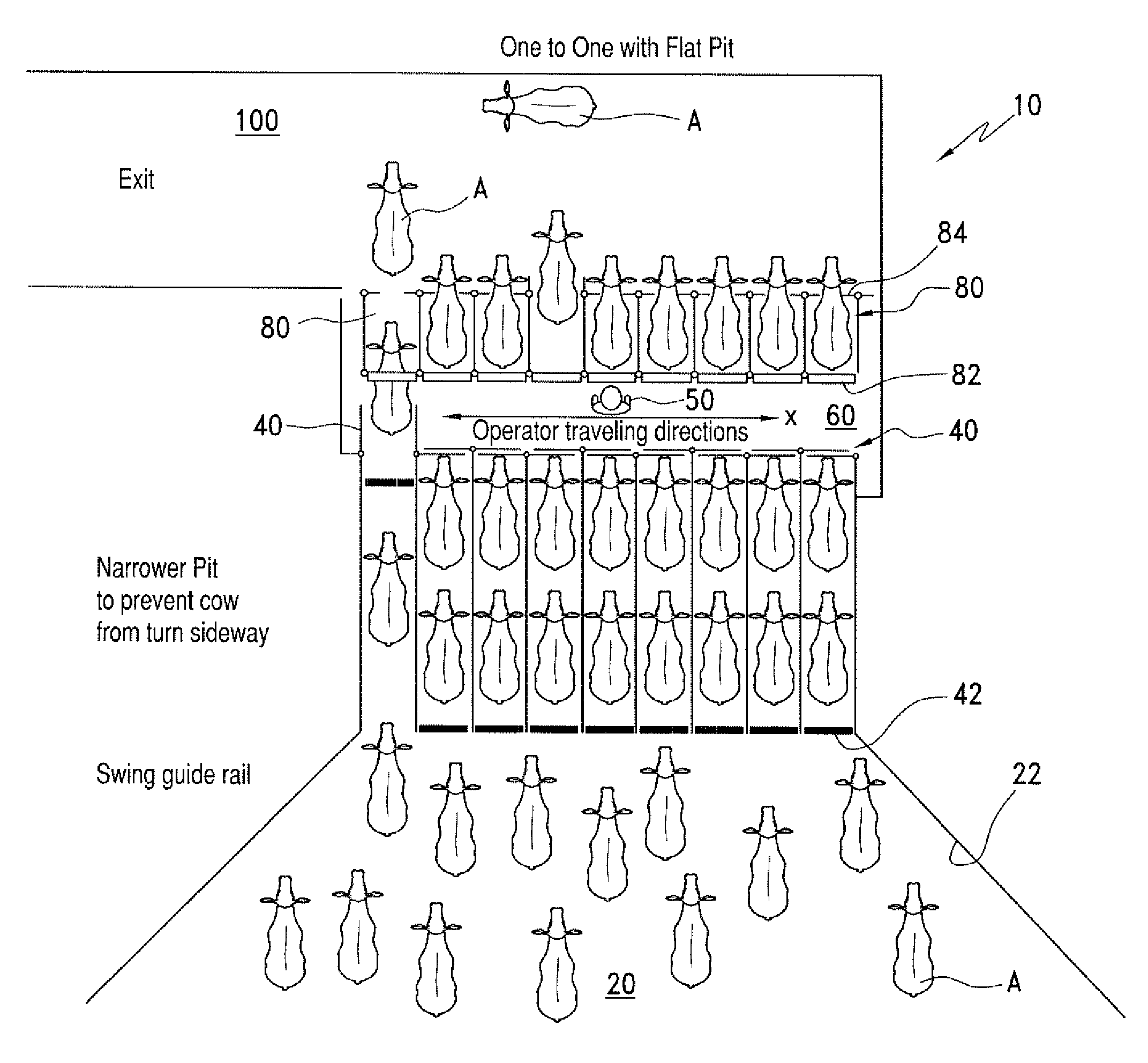

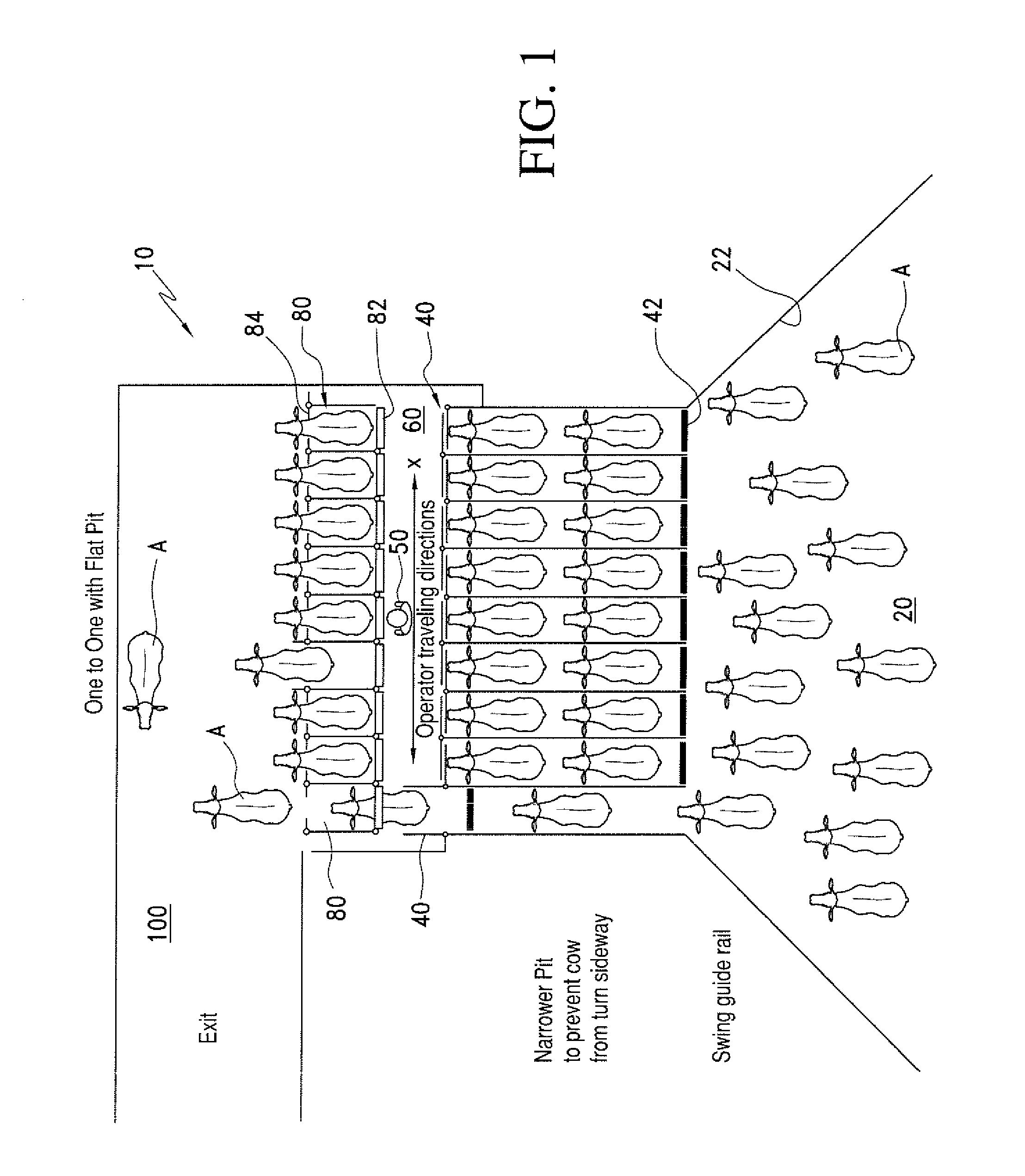

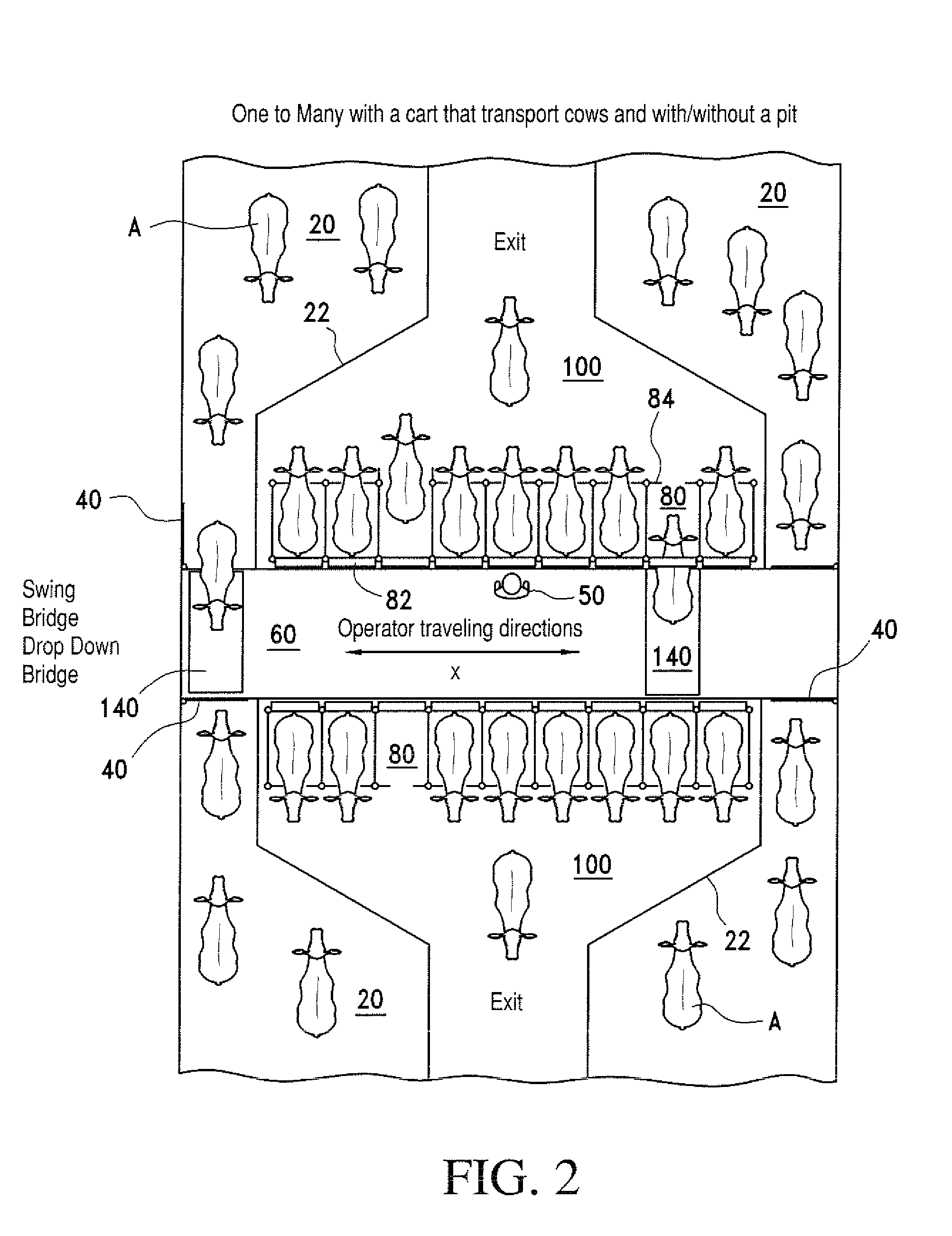

[0048] The milking parlor provides for a method of individually presenting an animal to be milked, including forwardly loading the animal into a milking stall through a rear ingress gate of the milking stall; milking the animal; and forwardly unloading the animal from the milking stall through a front egress gate. In a preferred configuration, the animal does not change a direction of travel during loading, milking and unloading. That is, the animal does not navigate any turns, and ambulates along a single forward straight path. Further, the milking stalls can be oriented to provide for rear milking (similar to a conventional parallel parlor operation), or underneath milking, or side milking (similar to a conventional herringbone parlor operation) of the animals. Prior to loading the animal into the milking stall, it is contemplated the animal can be led from a holding gate. In a further em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com