Automatic rear airfoil for vehicle

a rear airfoil and automatic technology, applied in vehicle body streamlining, monocoque construction, vehicle body, etc., can solve the problems of reducing the drag of the backlight, reducing and reducing the performance of the backlight, so as to reduce the weight of the airfoil, reduce the weight of the backlight, and reduce the weight of the structural reinforcement. , the effect of reducing the weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

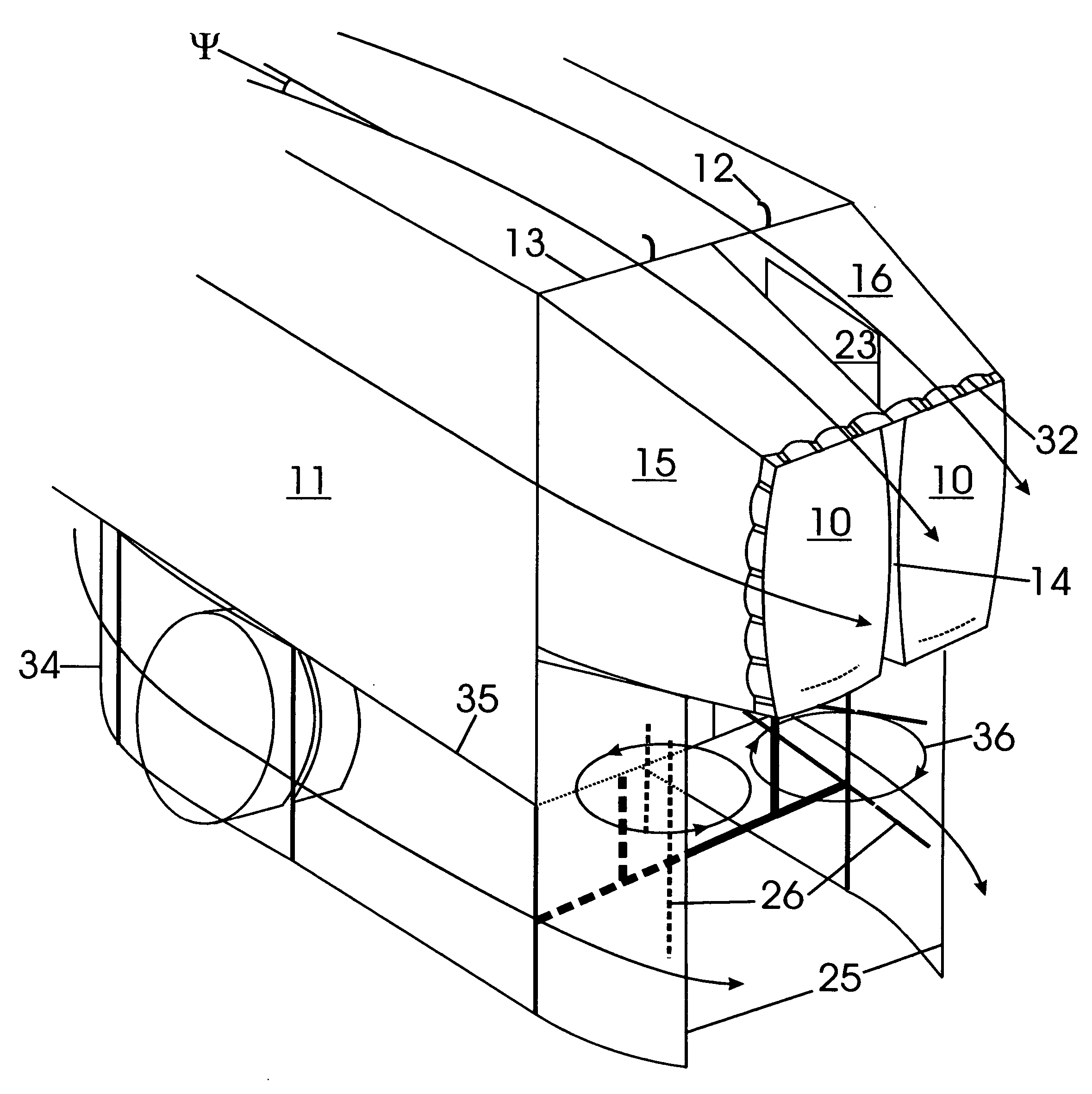

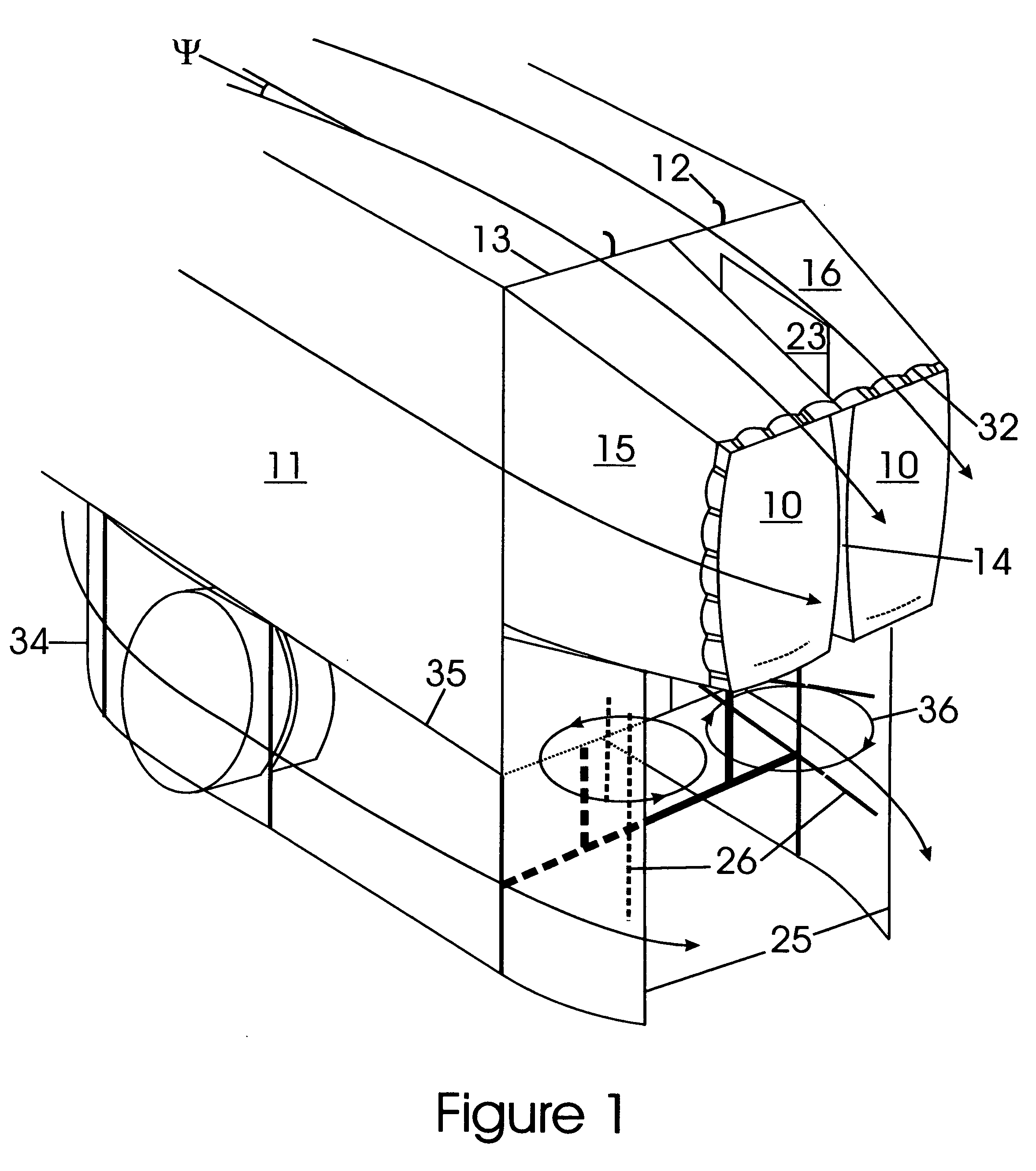

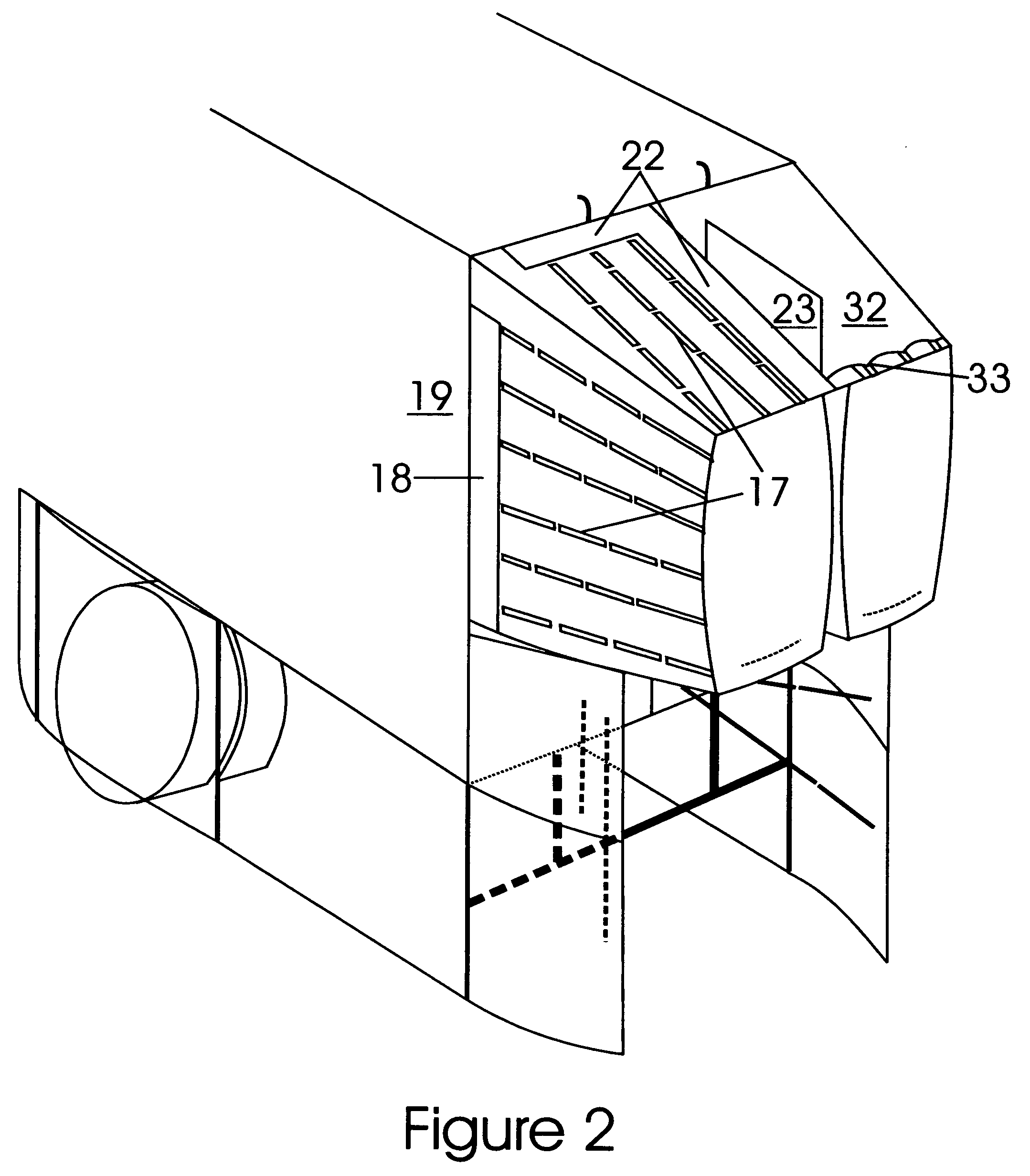

[0009] The device is comprised of a pair of inflatable bags 10 that are inflated upon forward motion of the trailer 11 by ram air intake scoops 12 that extend above the trailer roof line 13 from each bag 10. The bags 10 are pressed together along a central cleft 14 when inflated, and this union has a stabilising effect on the apparatus. The boattail 15 and backlight 16 surfaces are reinforced by a series of staggered interrupted ribs 17 to create rigidity during inflation, while enabling complex folding during deflation. A boattail shelf 18 is fixed to the boattail surface 15 and extends forwardly to meet the trailer side 19. The boattail surface 15 is anchored to the medial edge 20 of the base of each bag via a series of cords 21 that extend radially from the medial edge 20 to the boattail surface 15. A backlight shelf 22 is fixed to the backlight surface 16 and extends forwardly to meet the trailer roof line 13, and medially to meet the opposite shelf. A yaw control fin 23 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com