Vacuum breaker

a vacuum breaker and breaker technology, applied in water installations, thin material processing, construction, etc., can solve the problems of water pressure drop in the pipe of the plumbing fixture, pollute the clean water supply, complicated and high cost, etc., and achieve simple and inexpensive structure for assembly and manufacture, reliable back flow protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

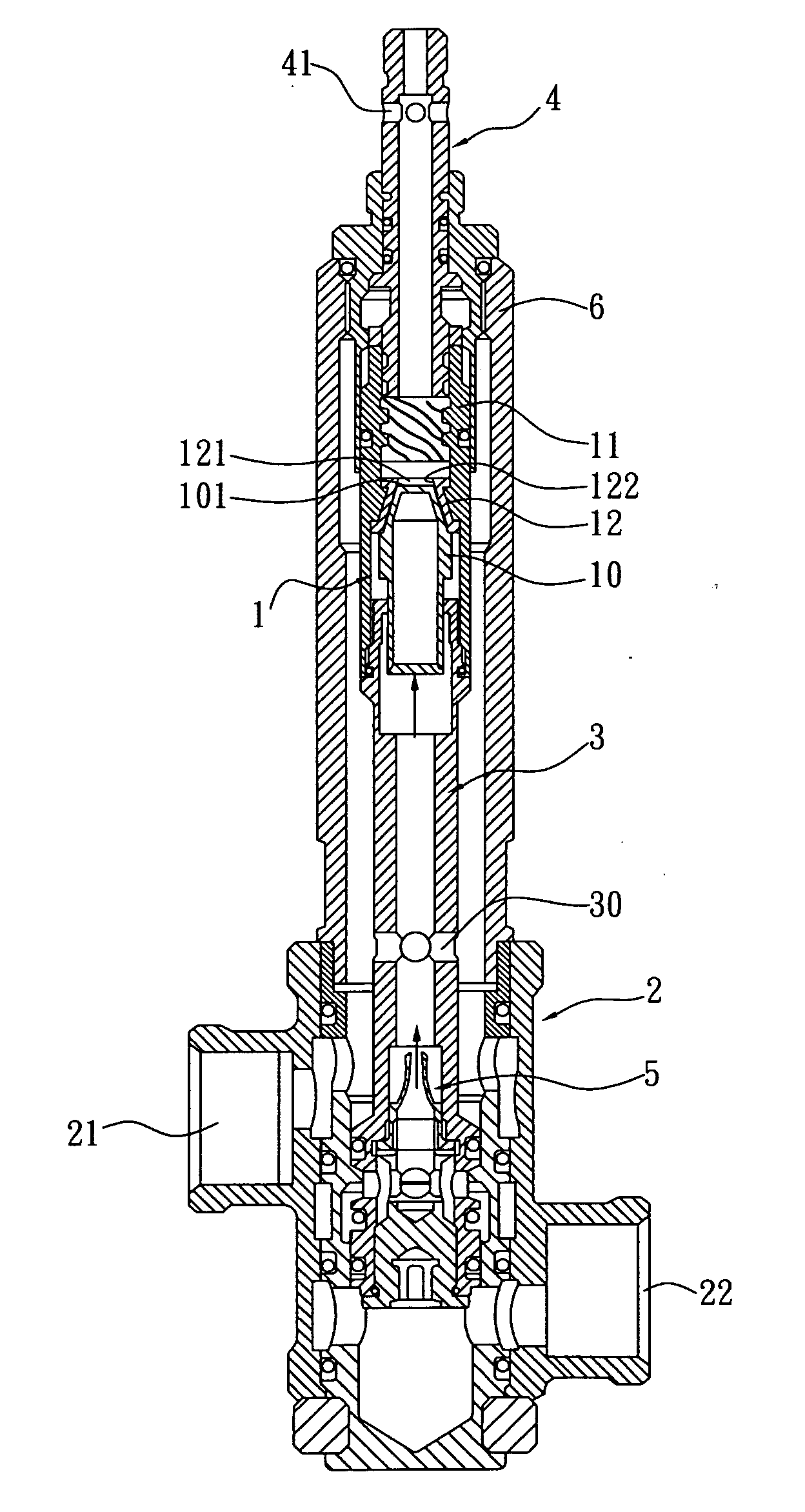

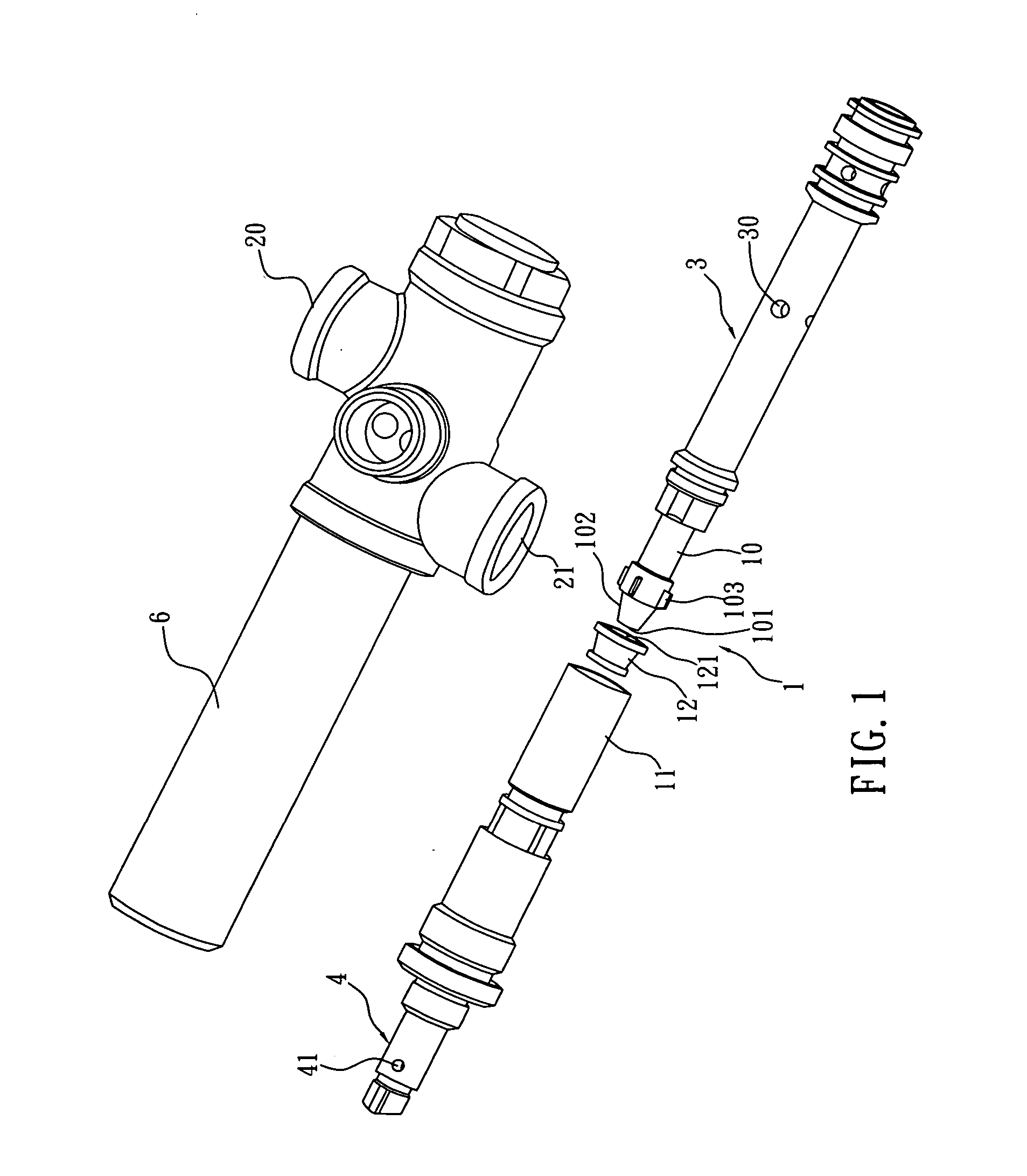

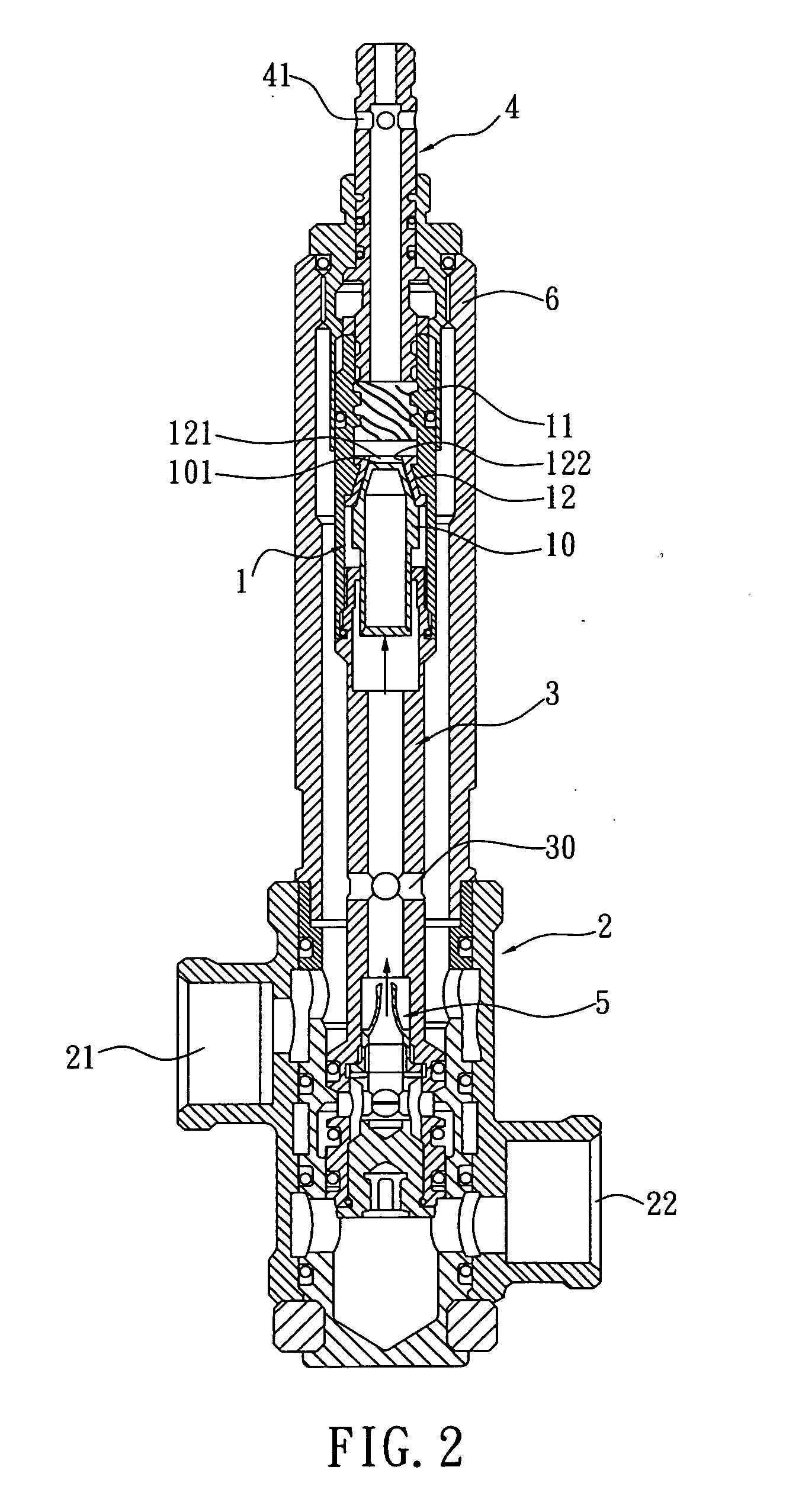

[0014] Referring to FIGS. 1 and 2, a vacuum breaker 1 in accordance with a preferred embodiment of the present invention is disposed at a water diverter connected to a water supply and a shower tap. The vacuum breaker 1 in accordance with the present invention may also be mounted in a plumbing fixture for kitchen sinks or in a shower tap. The water diverter includes a pipe connector 2. The pipe connector 2 has a first water outlet 21 and a second water outlet 22 that are respectively connected to a hand held device such as a showerhead and a spout of the shower tap.

[0015] The diverter valve further includes a housing 6 and a central shaft 3 disposed in the housing 6. The housing 6 is connected with the pipe connector 2. The central shaft 3 is partially held in and by the pipe connector 2 and is hollow with two end openings. One of the end openings of the central shaft 3 is connected with a bushing 11, and the other end opening is connected with a check valve 5. The bushing 11 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com