Contact image sensor and image reader

a contact image sensor and image reader technology, applied in the field of image readers, can solve the problems of general difficulty in realizing an accurate orthogonal relationship between the axial direction of the guide shaft and the longitudinal direction of the contact image sensor, and achieve the effect of low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

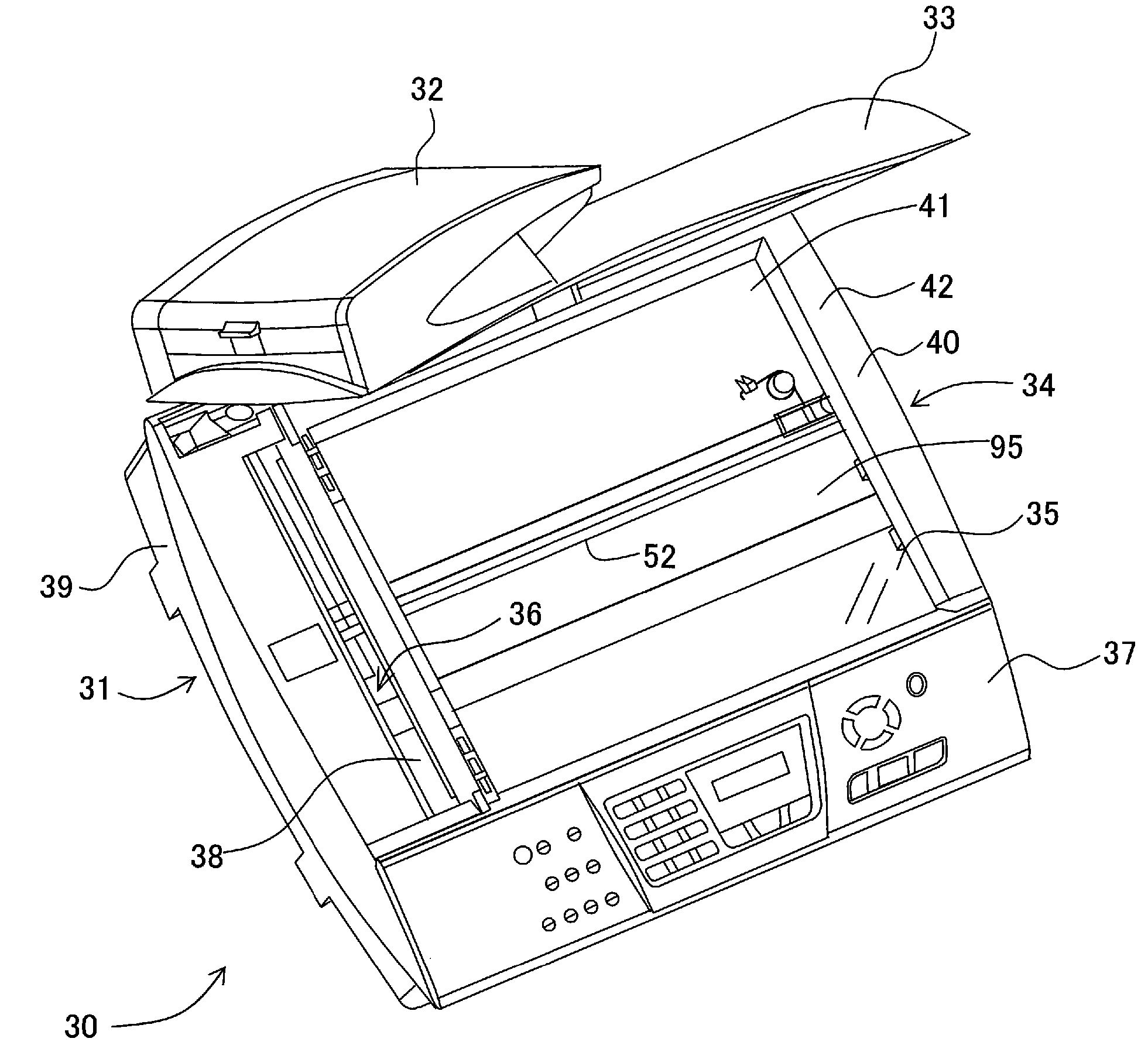

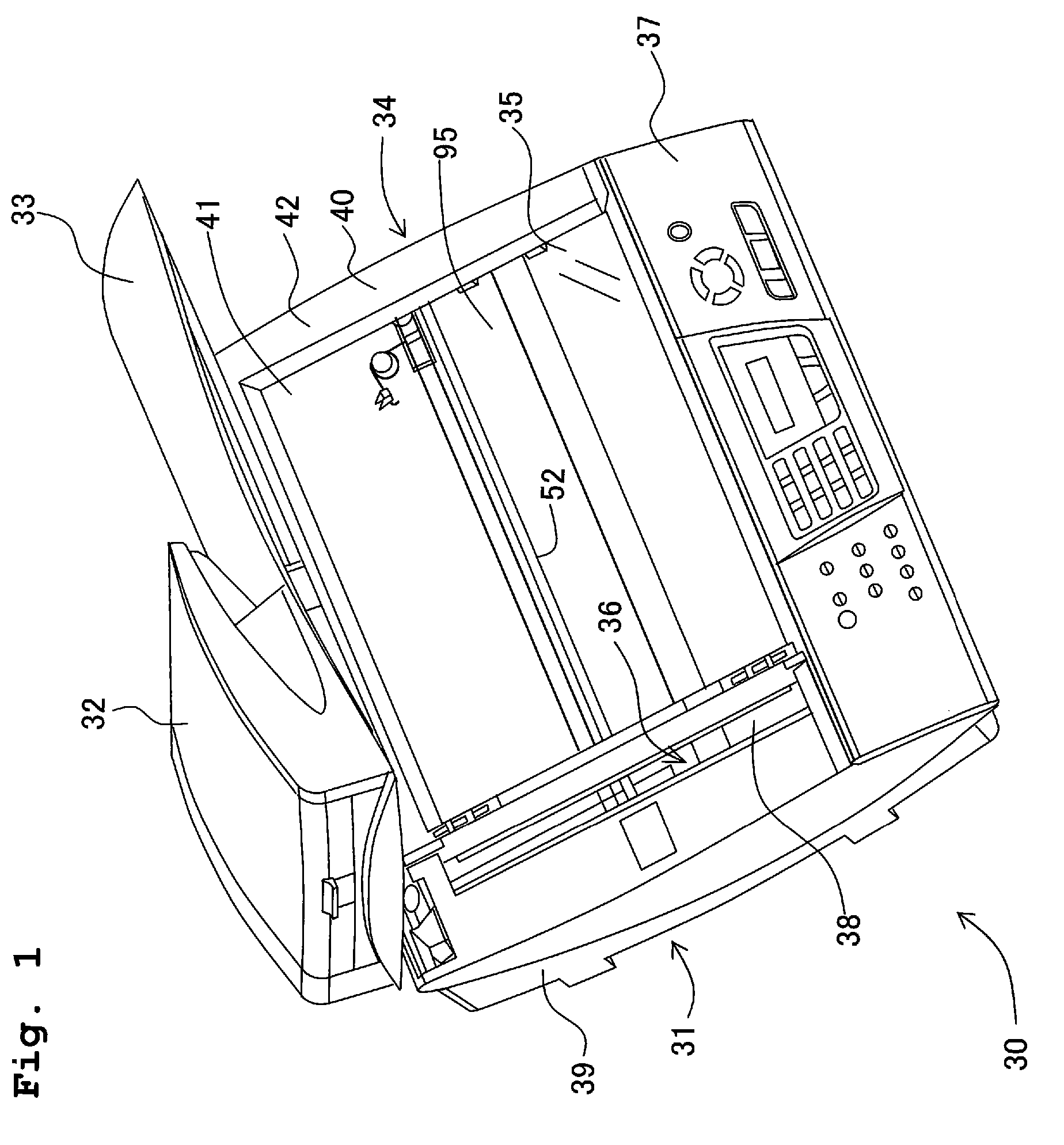

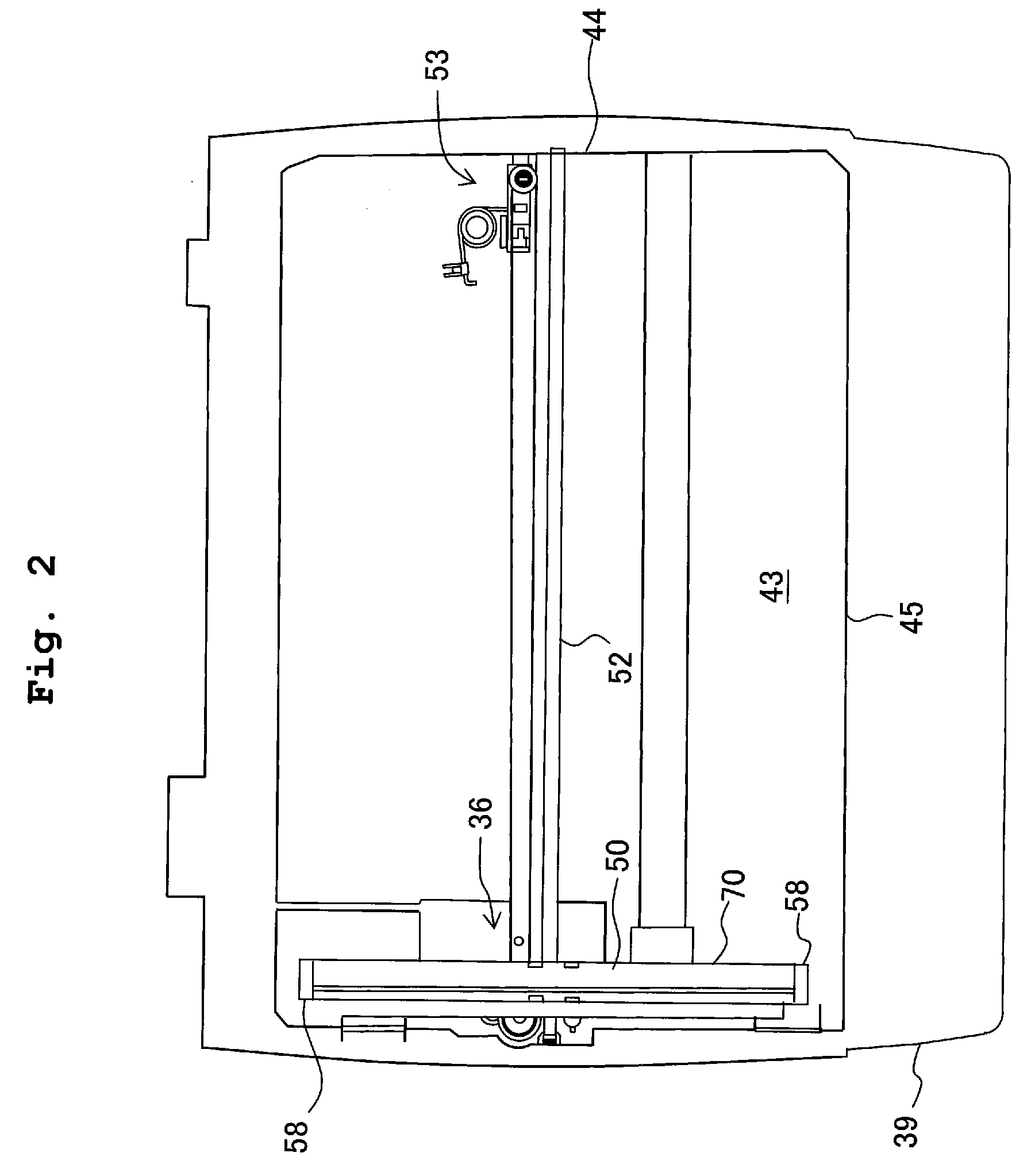

[0080]FIG. 1 is an external perspective view of an the image reader 30 according to a first embodiment of the present invention.

[0081] This image reader 30 may be used, for example, as a scanner unit of a multi function device (MFD) which is integrally equipped with a printer function and a scanner function, or as an image reading unit of a copier. In the present invention, the printer function is an arbitrary mechanism, and the image reader 30 may be constructed as a flatbed scanner (FBS) having the scanner function only.

[0082] As shown in FIG. 1, this image reader 30 has a reading platform 31 (document placing / reading platform) which functions as an FBS, and a document pressing cover 33 is mounted onto the reading platform 31 in an openable / closable manner. This document pressing cover 33 has an auto document feeder (ADF) 32. The reading platform 31 has a body frame 34 (casing) of substantially rectangular parallelepiped shape, a contact glass plate (light transmitting plate) 35...

second embodiment

[0120] A second embodiment of the present invention will now be explained.

[0121]FIG. 9 is an enlarged perspective view of principal portions of an image reading unit of an image reader according to a second embodiment of the present invention.

[0122] The image reading unit according to this embodiment differs from the image reading unit according to the above-described first embodiment in that, although in the first embodiment, the guide shaft 52 supports the CIS unit 50 in a slidable manner in the short direction and the guide shaft 52 is elastically urged upward by the coil springs 63, whereas in the second embodiment, the guide shaft 52 passes through a CIS unit 140 in a state in which the CIS unit 140 is movable in the vertical direction (the direction orthogonal to both the longitudinal direction and the short direction); and slide rollers 141 and 142 as sliding member provided on the CIS unit 140 elastically urge the CIS unit 140 upward and aid smooth sliding of CIS unit 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com