Spinal correction system with multi-stage locking mechanism

a locking mechanism and spine technology, applied in the field of spine correction, can solve the problems of less manageable installation steps and additional parts, and achieve the effect of sufficient “flexion” and facilitate the flexion of the head-body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Broadly, this invention resides in a rod fixation system to treat various spinal conditions, wherein the same fastener is used to lock both a polyaxial screw and a rod in position. Although the invention is described in conjunction with rod fixation, extensions to rod and plate or plate-only configurations are possible.

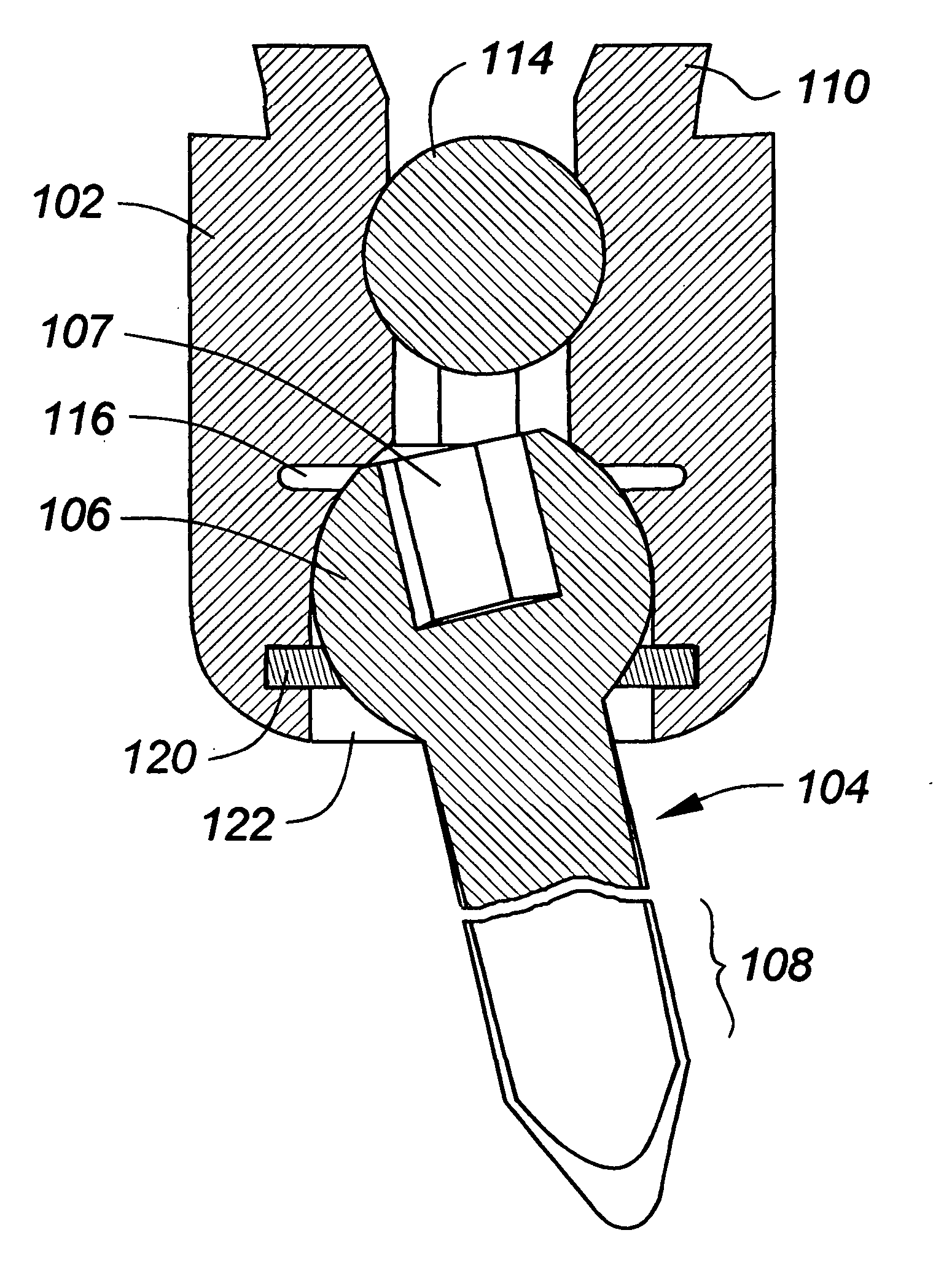

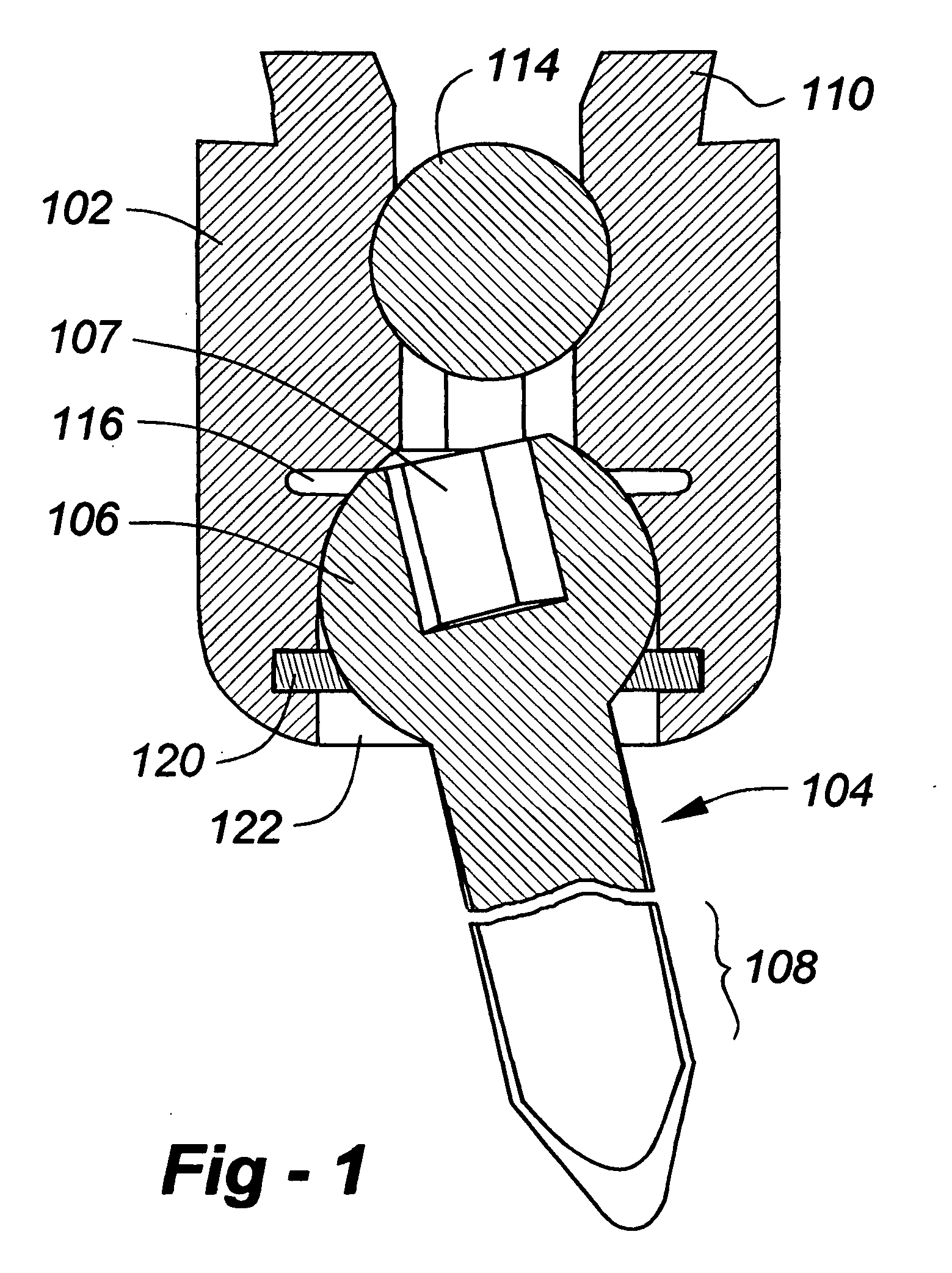

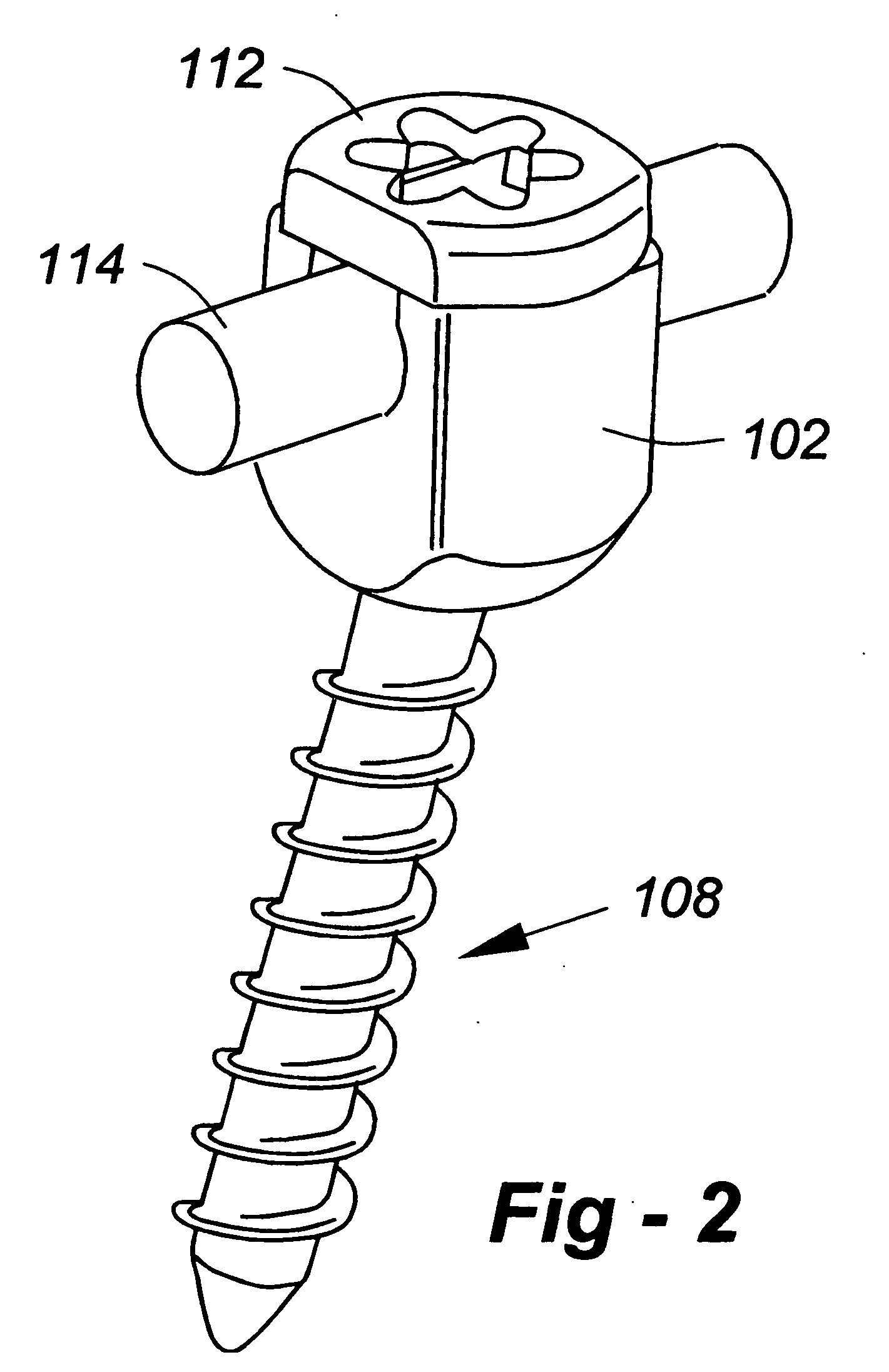

[0015] Reference is now made to FIGS. 1 and 2, which show from a cross-section and oblique view, respectively, a first preferred embodiment of the invention utilizing three primary components, namely, a head-body 102, a polyaxial screw 104, and a cap 112 (not shown in FIG. 1). The polyaxial screw 104 includes a proximal hemispherical head 106 and a distal threaded portion 108. The ball portion of the screw includes some type of turning aperture, such as hex depression 107. The screw 104 is held in position within the head-body 102 through bushing 120 and fastener 122, facilitating assembly from the bottom. The fastener 122 may be threaded, press fit or otherwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com