Collapsible container for air shipment cargo and method of use

a container and air shipment technology, applied in the field of collapsible containers for air shipment cargo and the method of use, can solve the problems of container heavyness and container heavyness, and achieve the effect of quick and inexpensive assembly or erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

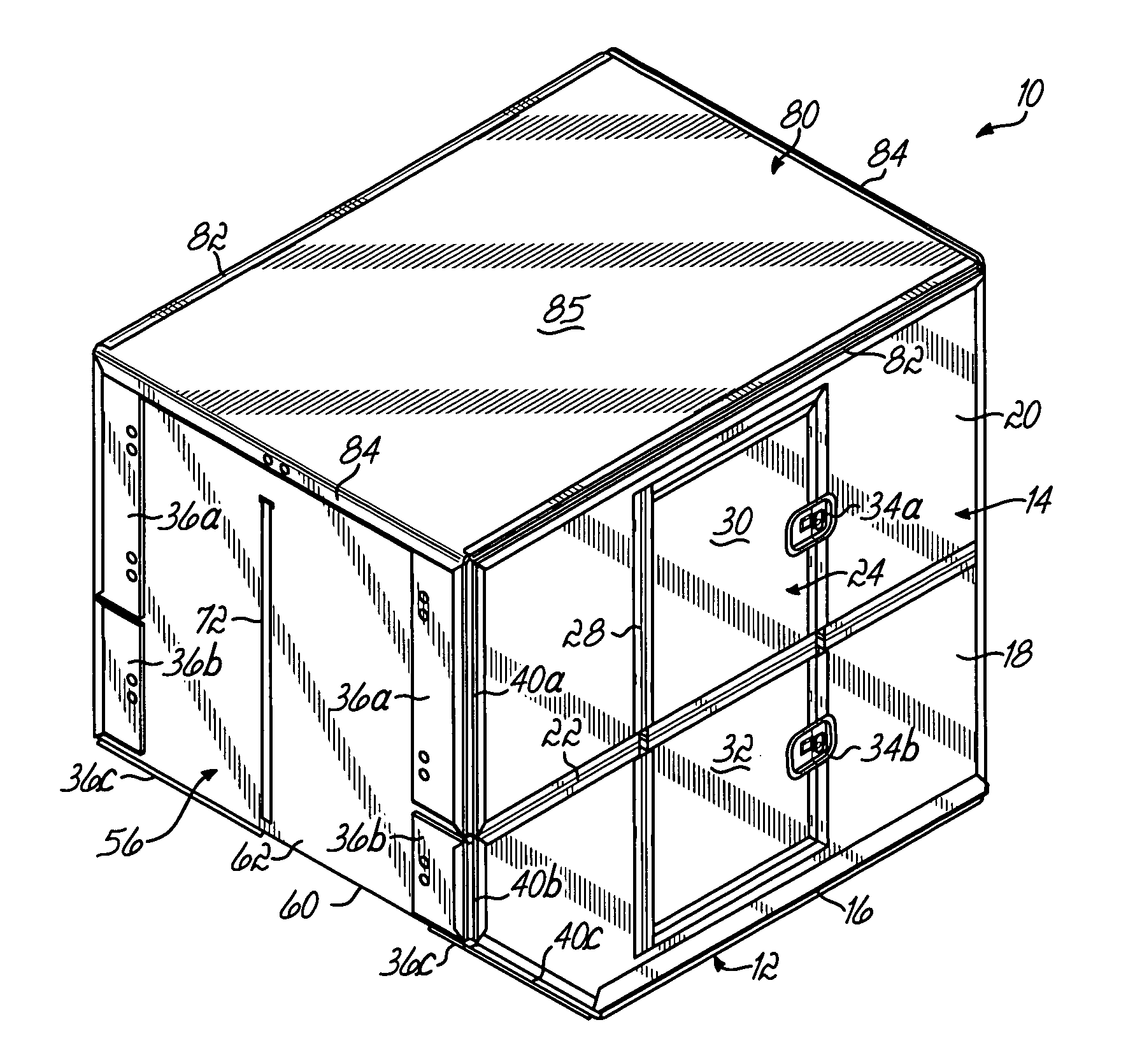

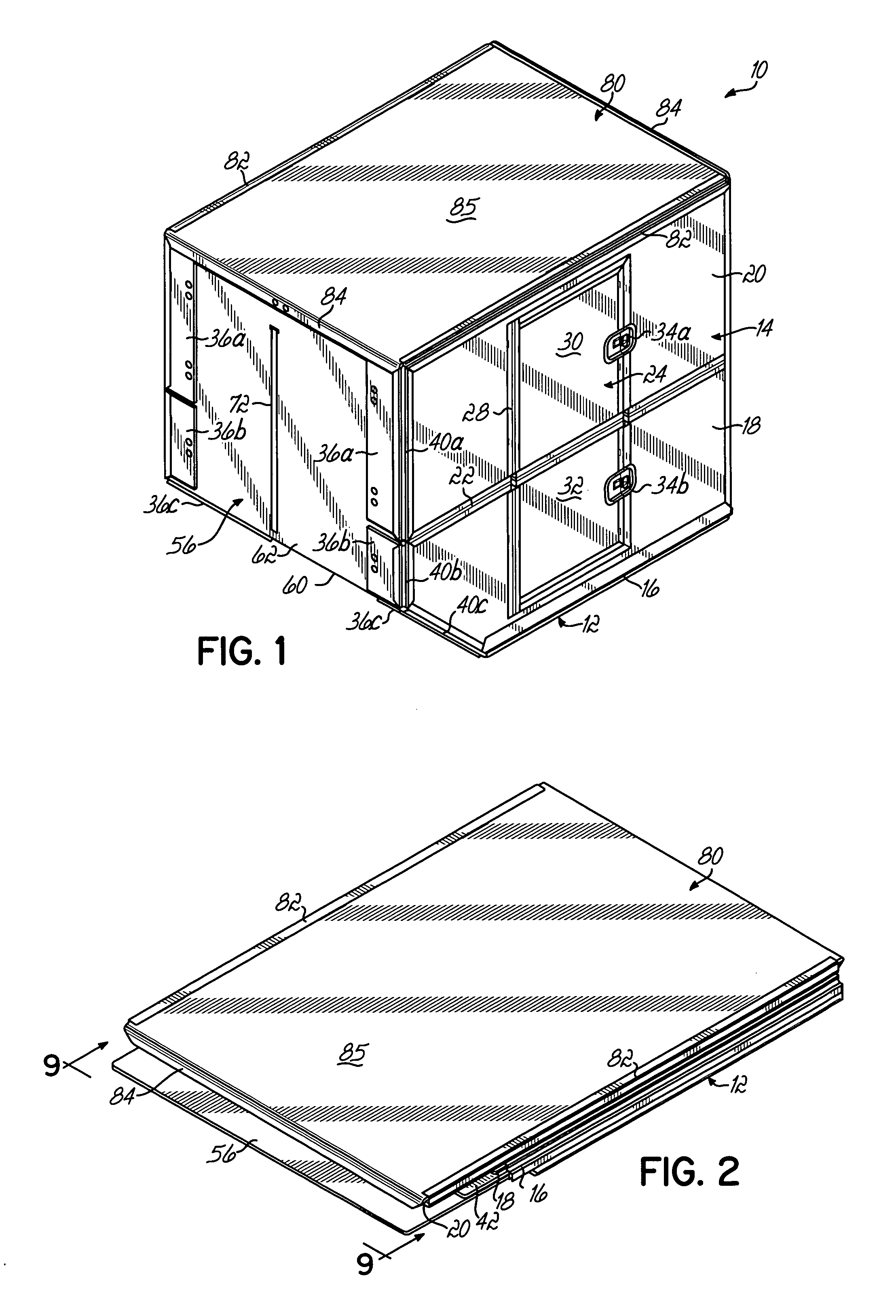

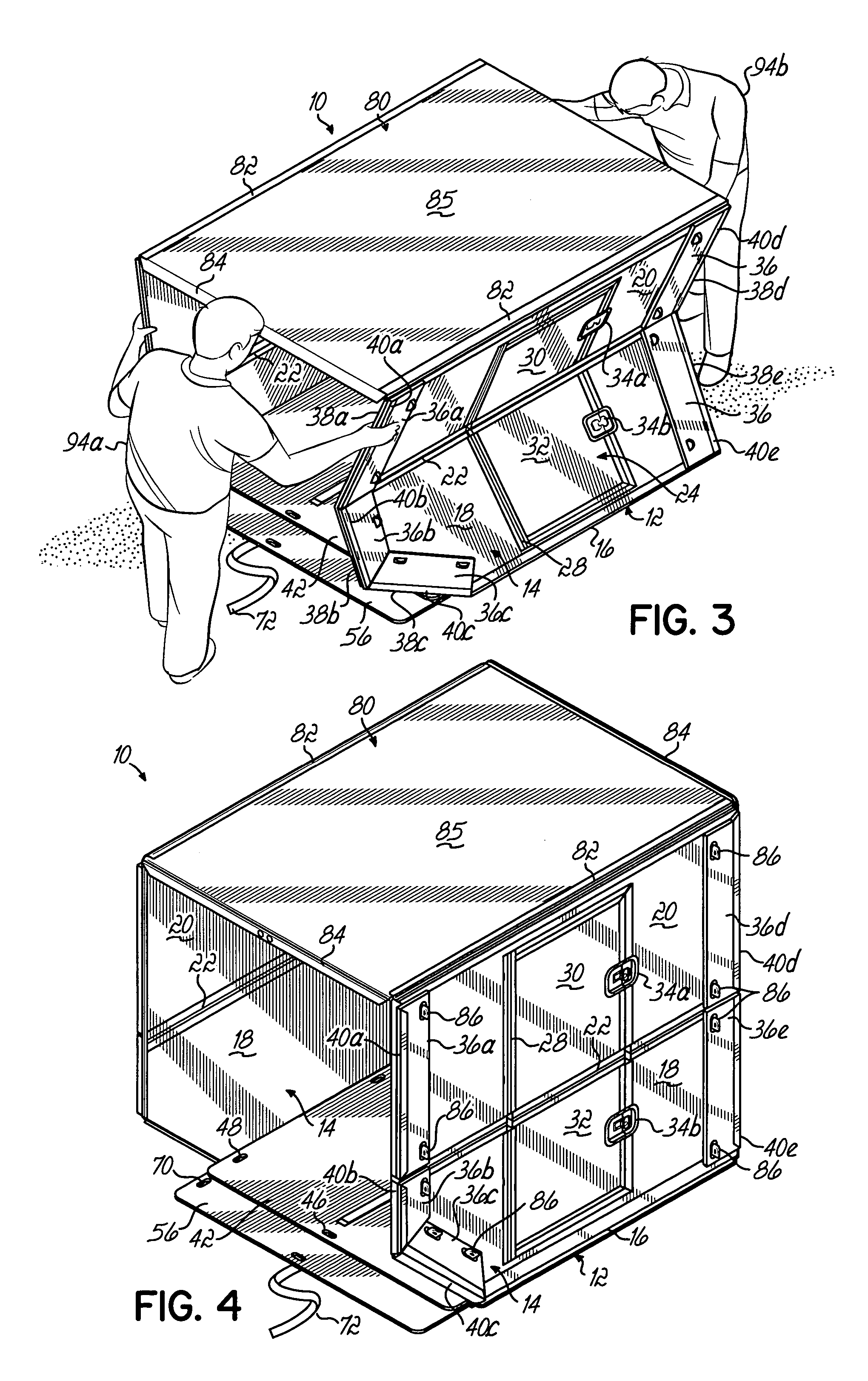

[0032] Referring to the drawings and particularly to FIG. 1, there is illustrated a collapsible container 10 movable between an erected condition or position illustrated in FIGS. 1 and 8 and a collapsed condition or position illustrated in FIGS. 2 and 9. The collapsible container 10 is designed for use inside an aircraft luggage hold but may be used in other environment or for any other purpose.

[0033] As best illustrated in FIG. 8, the collapsible container 10 comprises a generally rectangular and generally planar base 12 having an upwardly directed flange 13 around the periphery thereof. The base 12 is preferably made of one piece of plastic material. However, other materials or other configurations may be used without departing from the present invention.

[0034] Although reference is made to made in this document to a front wall panel, a rear wall panel and side walls, it will be appreciated that the collapsible container 10 may be oriented in any direction so that, for example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com