Golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

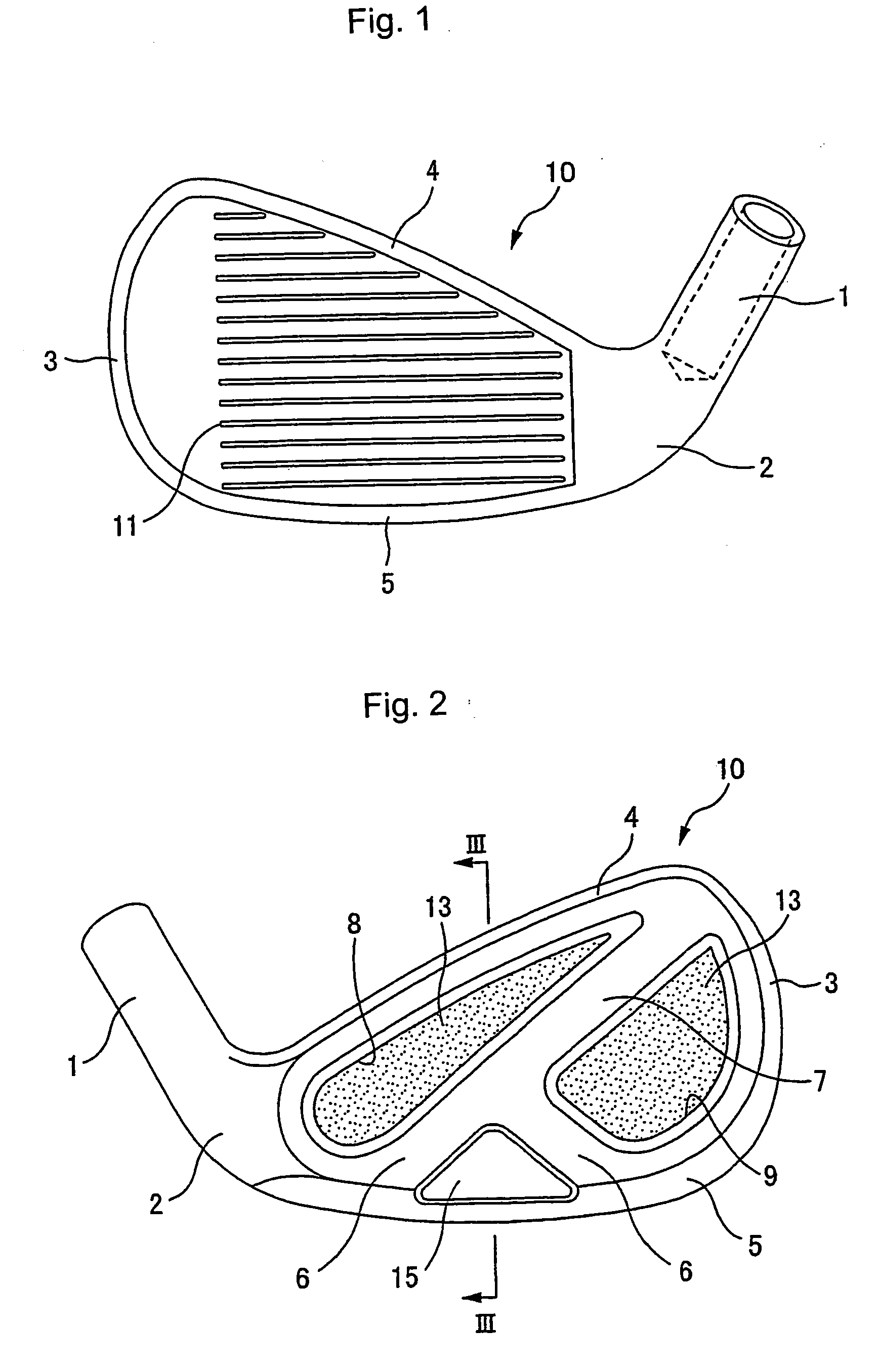

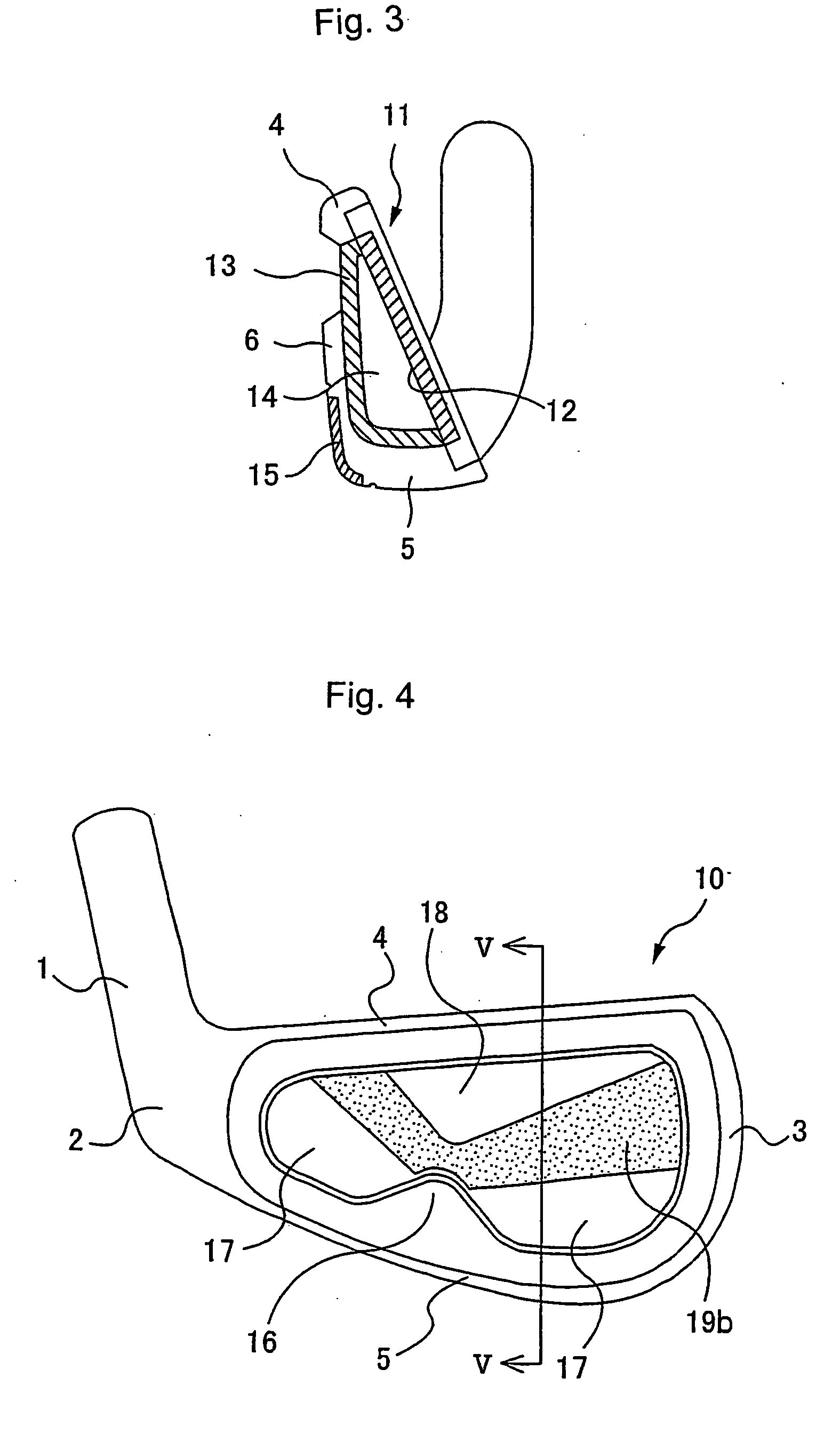

[0020] Hereinafter, a description is given of preferred embodiments of the present invention with reference to the accompanying drawings.

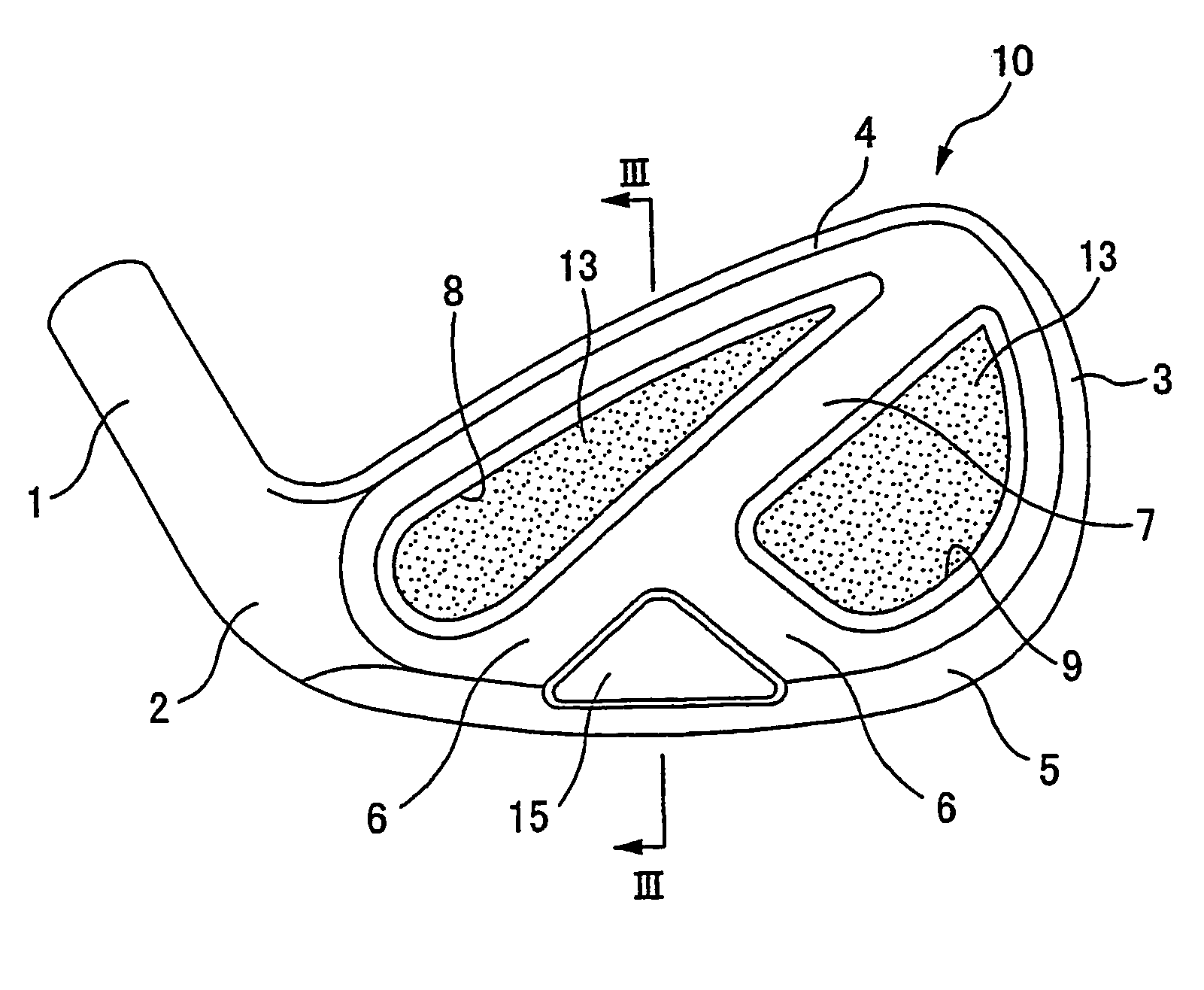

[0021] FIGS. 1 to 3 show an iron golf club head according to a preferred embodiment of the present invention. In the front view of FIG. 1, a head body 10 of the club head is formed in a frame-shape composed of a hosel section 1, into which a shaft (not shown) is inserted, a heel section 2 under the hosel section 1, a circular arc-shaped toe section 3, a belt-shaped upper edge section 4 connecting the upper ends of the heel section 2 and of the toe section 3, and a sole 5 connecting the lower ends of the heel section 2 and of the toe section 3.

[0022] As shown in FIGS. 2 and 3, on the back side of the head body 10, a chevron-shaped extension section 6 and a belt-shaped section 7 are provided. The chevron-shaped extension section 6 protrudes upward from the rear edge of the sole section 5 substantially at a right angle thereto. The belt-shaped exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com