Intraocular pressure measurement system including a sensor mounted in a contact lens

a technology of intraocular pressure and sensor, which is applied in the field of system for measuring intraocular pressure in the eye, can solve the problems of patient resistance to compliance, patient's actual risk of blindness may be misdiagnosed, and patient may be required to undergo therapy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

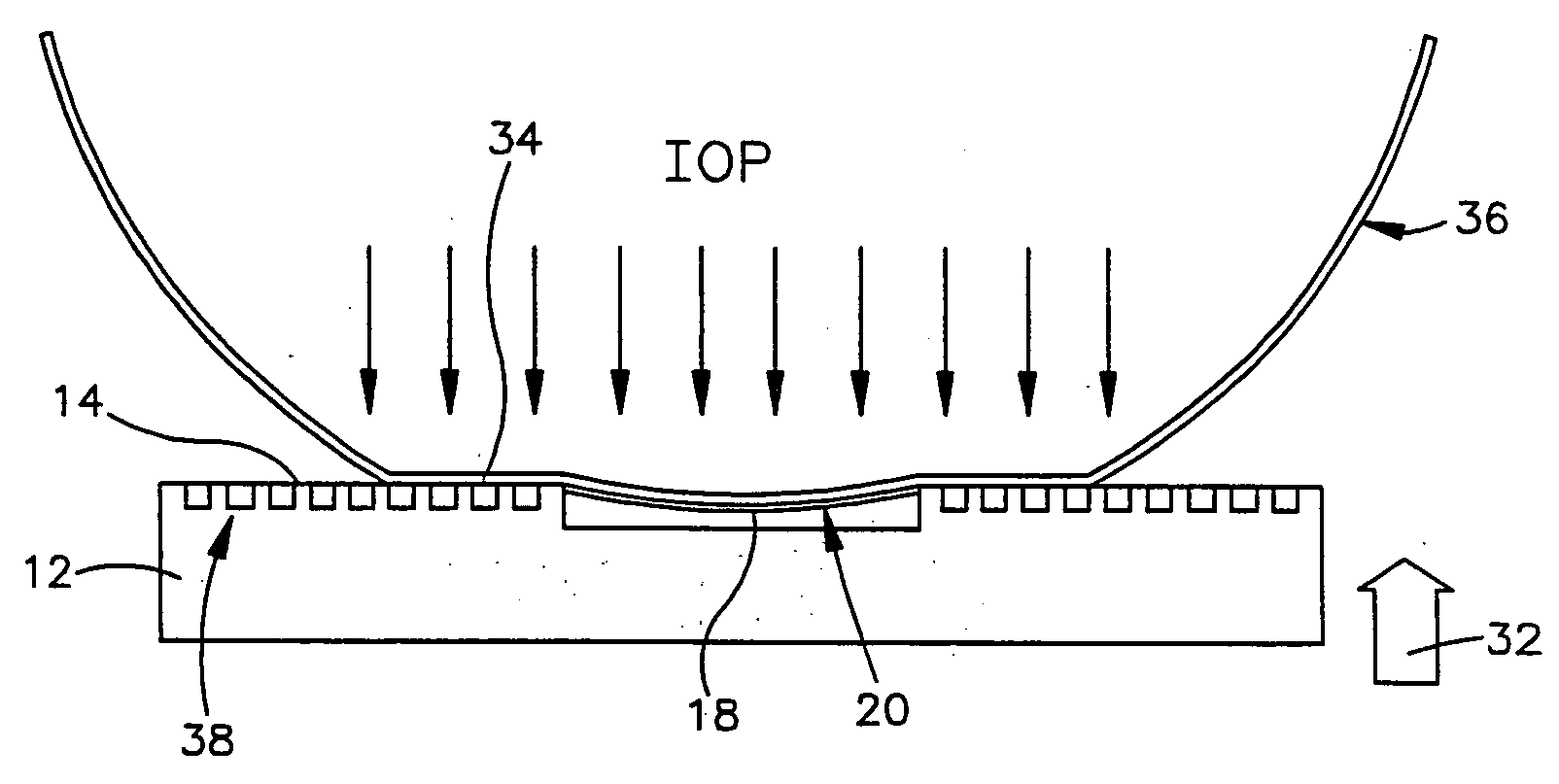

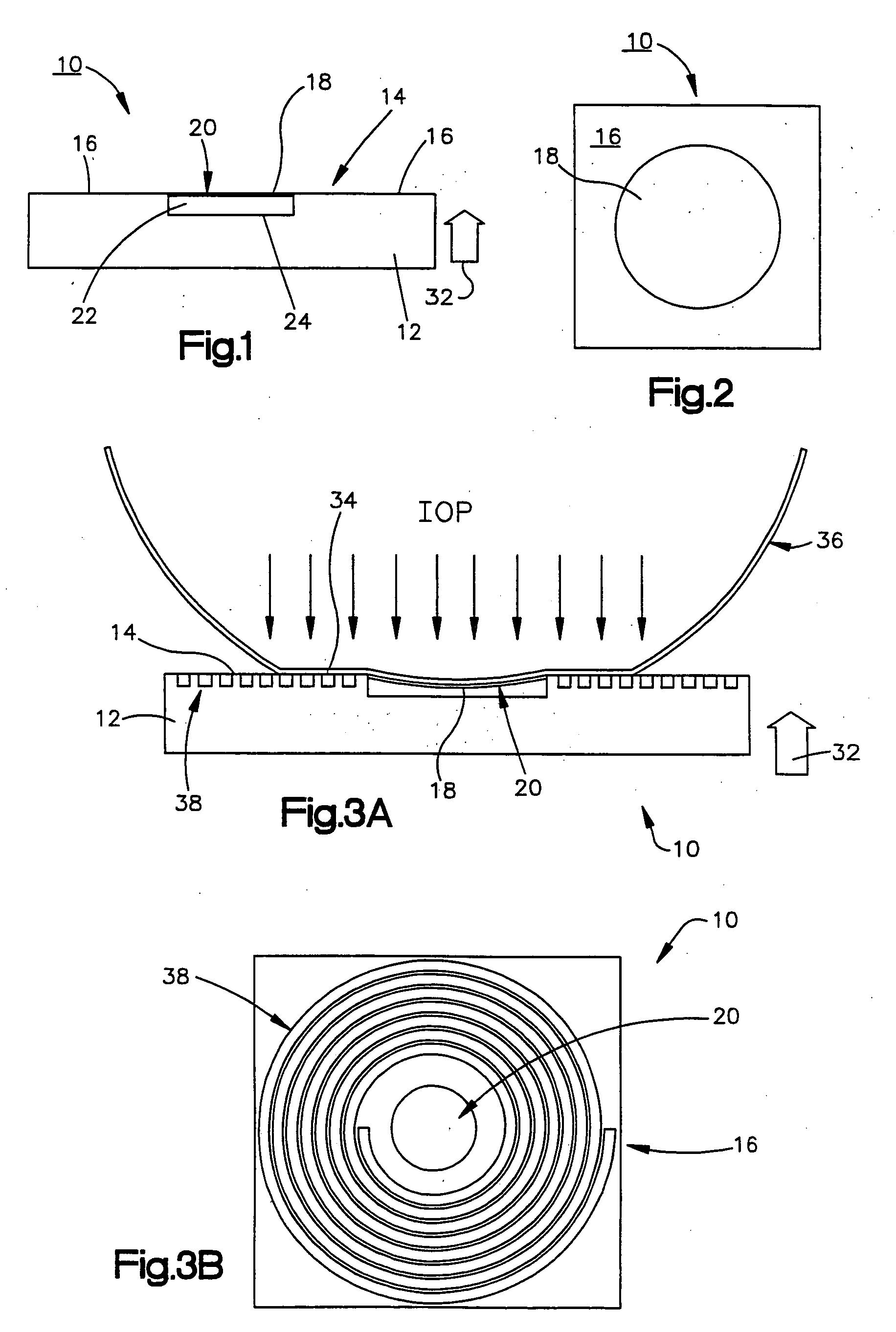

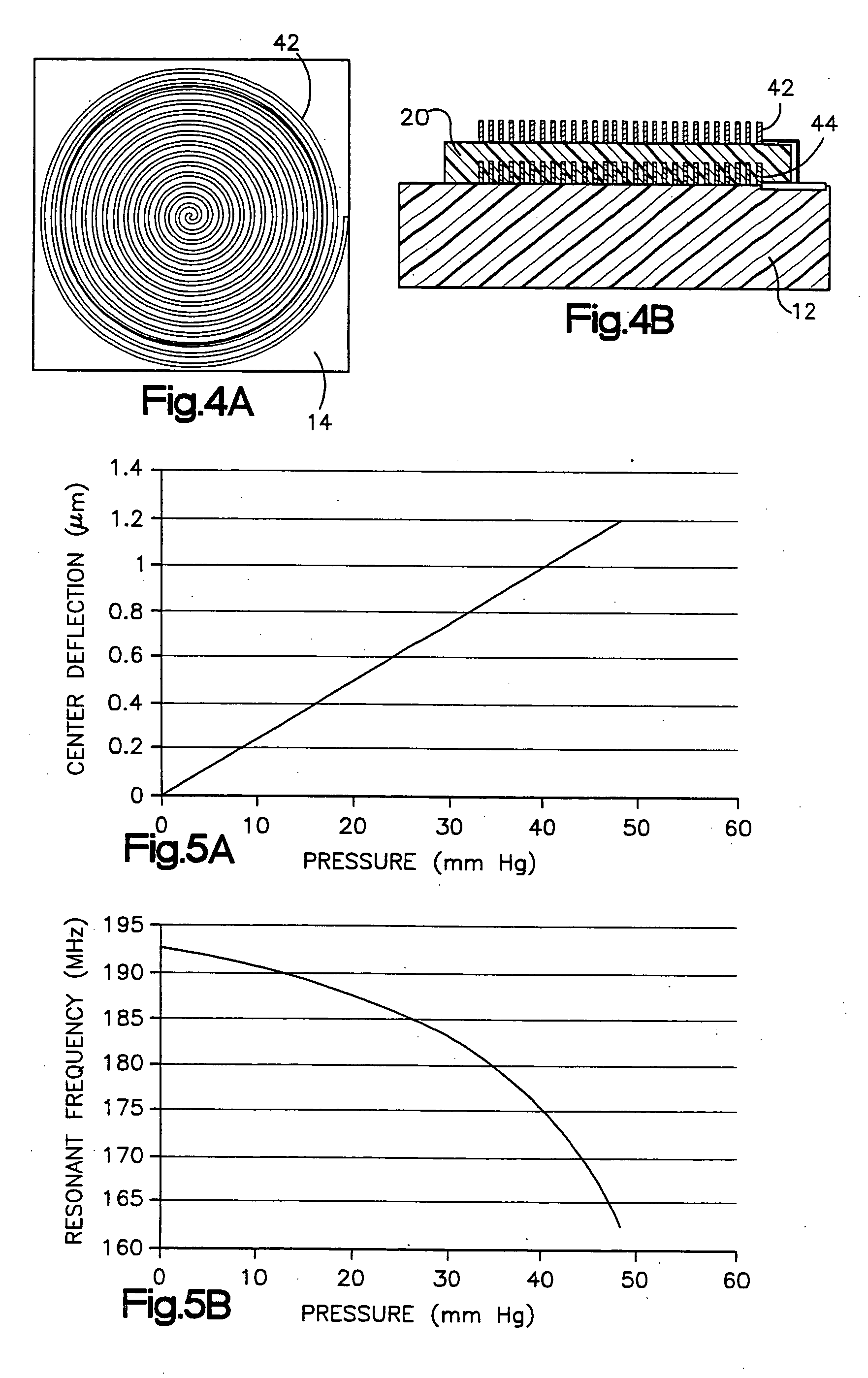

[0029] A tonometer sensor 10 produced using microelectromechanical system (MEMS) techniques is shown in FIGS. 1 and 2. The tonometer sensor 10 includes a substrate 12 that is comprised of a silicon material, but it should be understood that other materials may be used. The substrate 12 includes a contact surface 14 for making contact with a surface portion 34 (FIG. 3A) of an eye 36. The contact surface 14 includes an outer non-compliant region 16 (FIG. 1) and an inner compliant region 18 that is fabricated using MEMS techniques (which will be described in greater detail herein below) as an impedance element, the impedance of which varies as the inner compliant region 18 changes shape. The compliant region 18 comprises a diaphragm 20 as one plate of a capacitive element that is separated by a dielectric 22 from another plate 24 of the capacitive element which is part of the non-compliant region 16. As will become more-evident from the description below, as the contact surface 14 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com