Scissors lift utility tray assembly

a technology of utility tray and scissor lift, which is applied in the direction of scaffold accessories, transportation and packaging, building scaffolds, etc., can solve the problems of limited storage space, limited functionality of work platforms or decks, additional safety concerns, etc., and achieves the effect of convenient and quick attachment or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

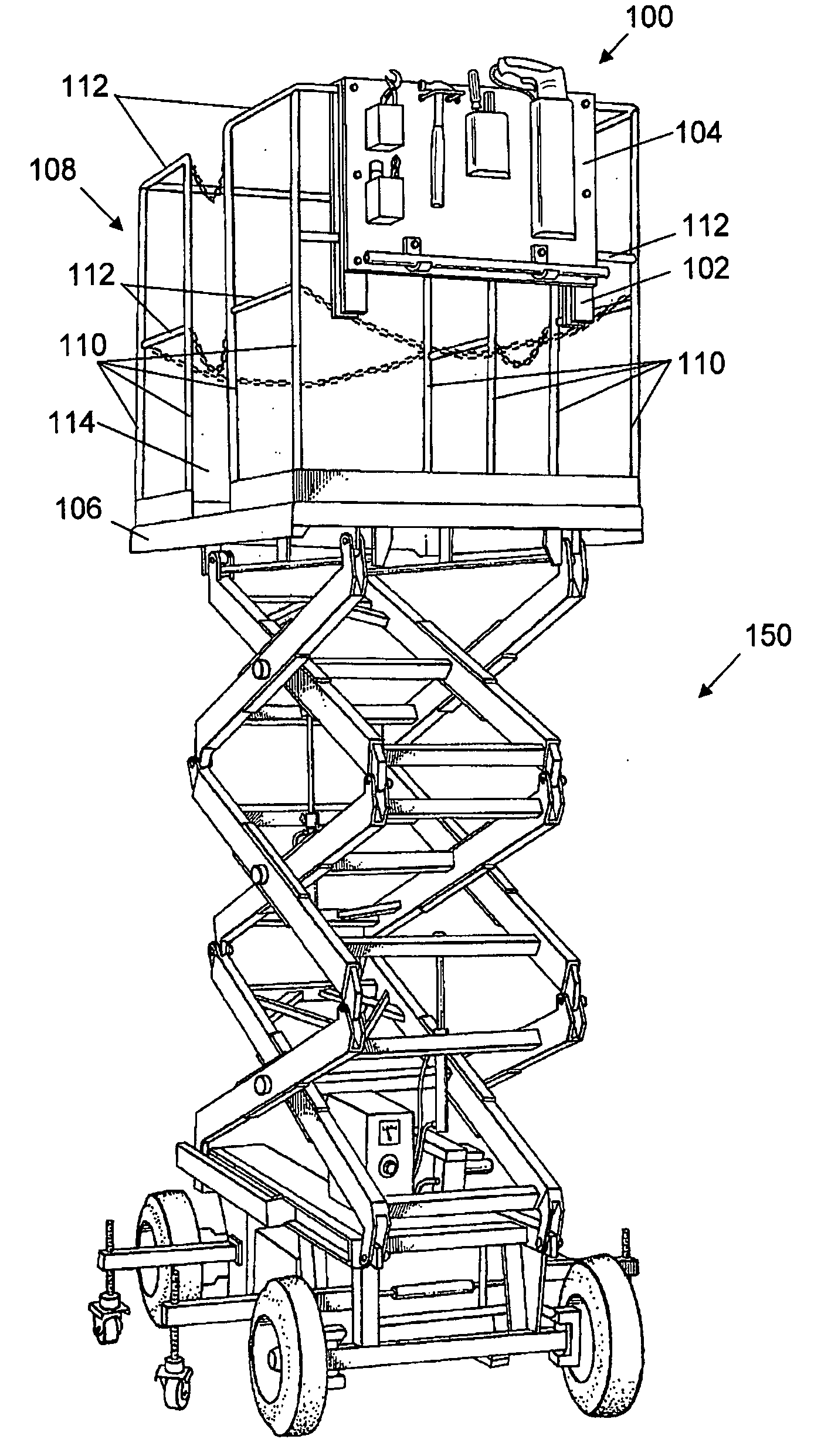

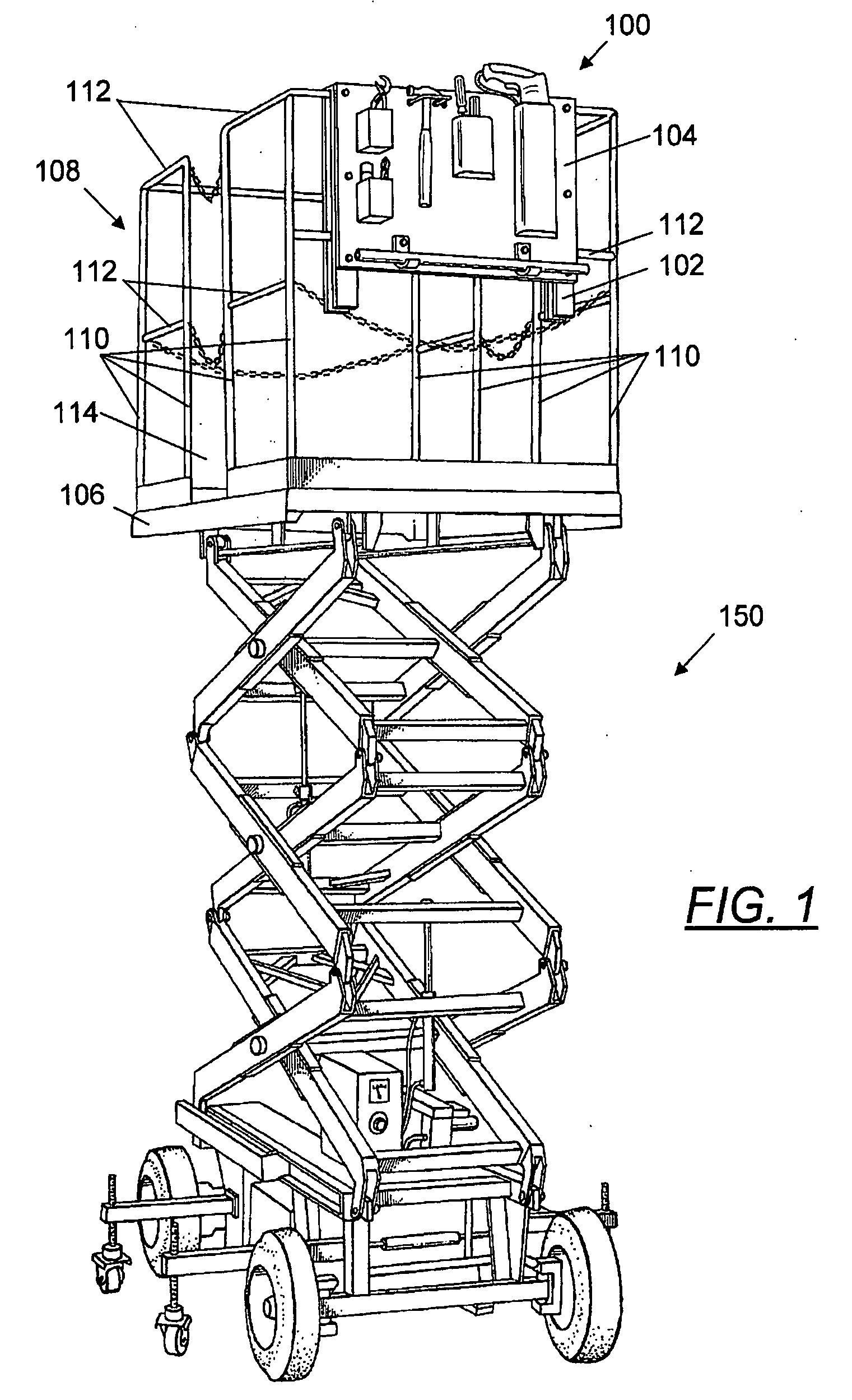

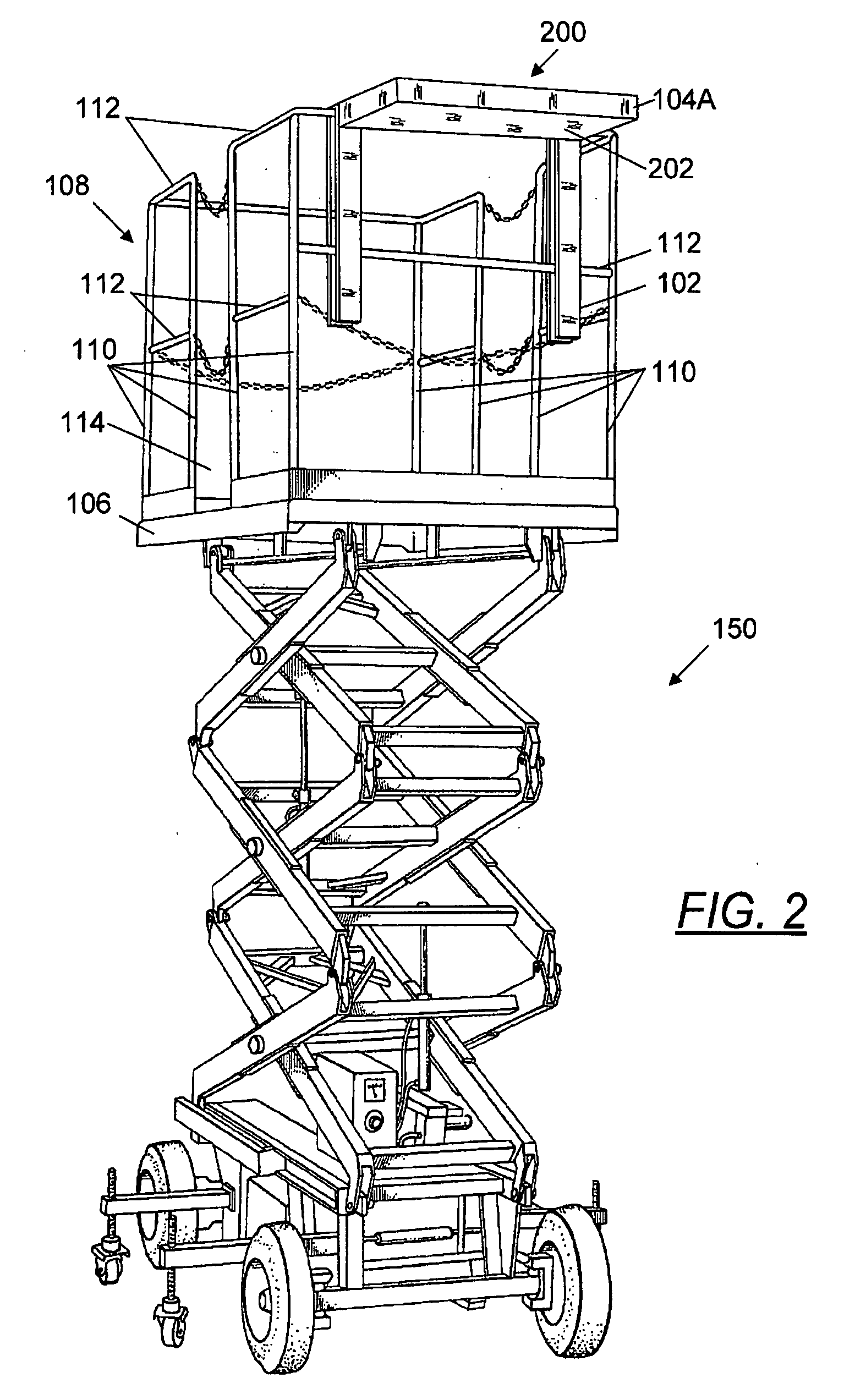

[0040]In accordance with this invention, there is provided an anti-sway stabilizer accessory support means and a utility tray assembly 100 which may be readily attached to a scissors lift 150 to provide convenient storage of frequently used items by a worker. FIG. 1 is a perspective view of the utility tray assembly 100 comprising a tray mount 102 and a utility tray 104 as it is mounted for use upon the scissors lift 150. The utility tray 104 is adjustably mounted to the tray mount 102. The tray mount 102 in turn is adjustably mounted to the scissors lift 150.

[0041]Referring to FIG. 1, the scissors lift 150 includes a horizontal deck 106 (working platform) partially enclosed by an upwardly depending safety support frame 108. Said safety support frame 108 includes a plurality of vertical members 110 and one or more horizontal members 112. The horizontal members 112 are connected between at least two of the vertical members 110. Said safety support frame 108 further includes a means o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com