Applicator system

a technology of application system and actuator, which is applied in the field of application system, can solve the problems of affecting the operation of the application device, and becoming permanently clogged with reacting substances,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

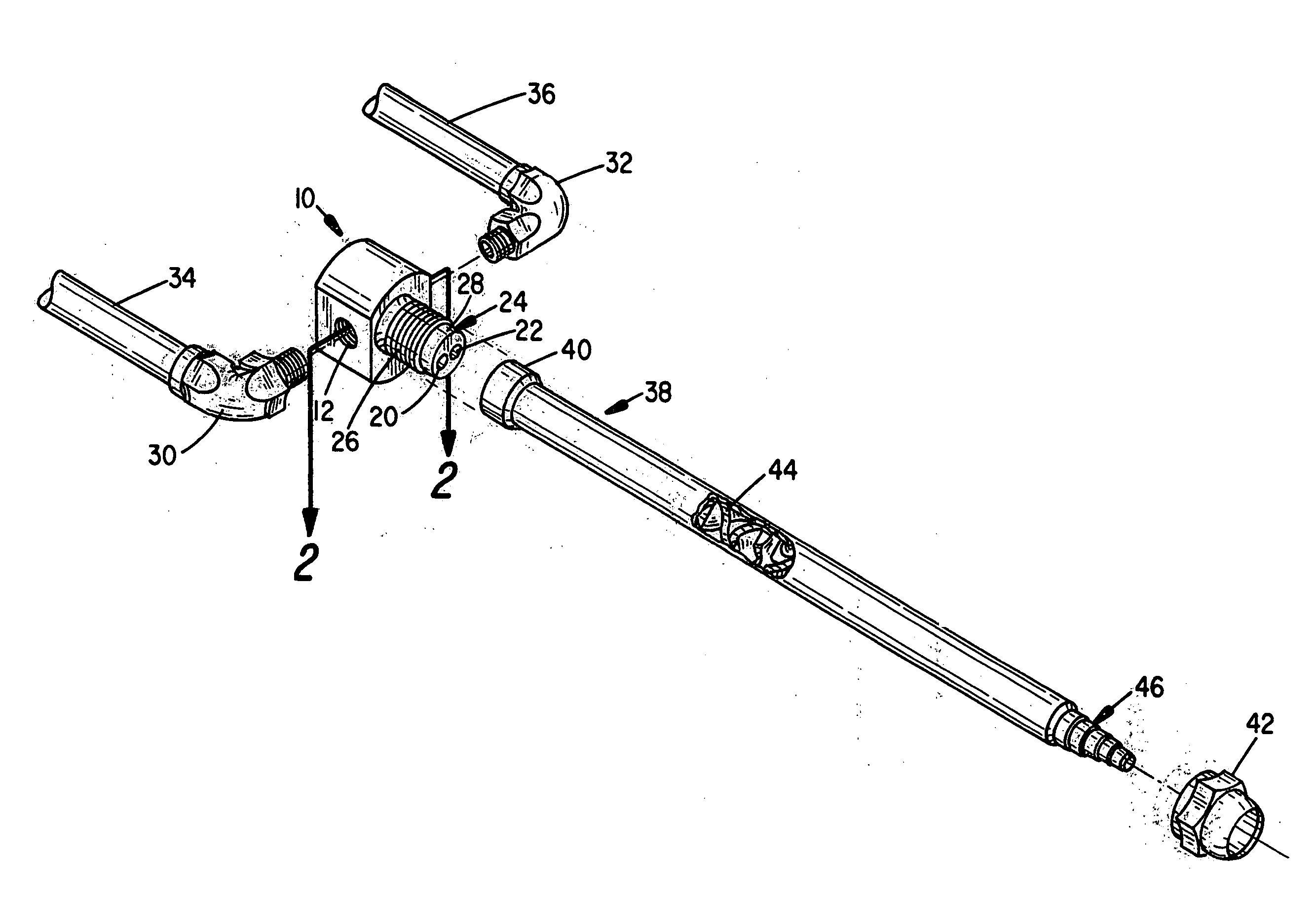

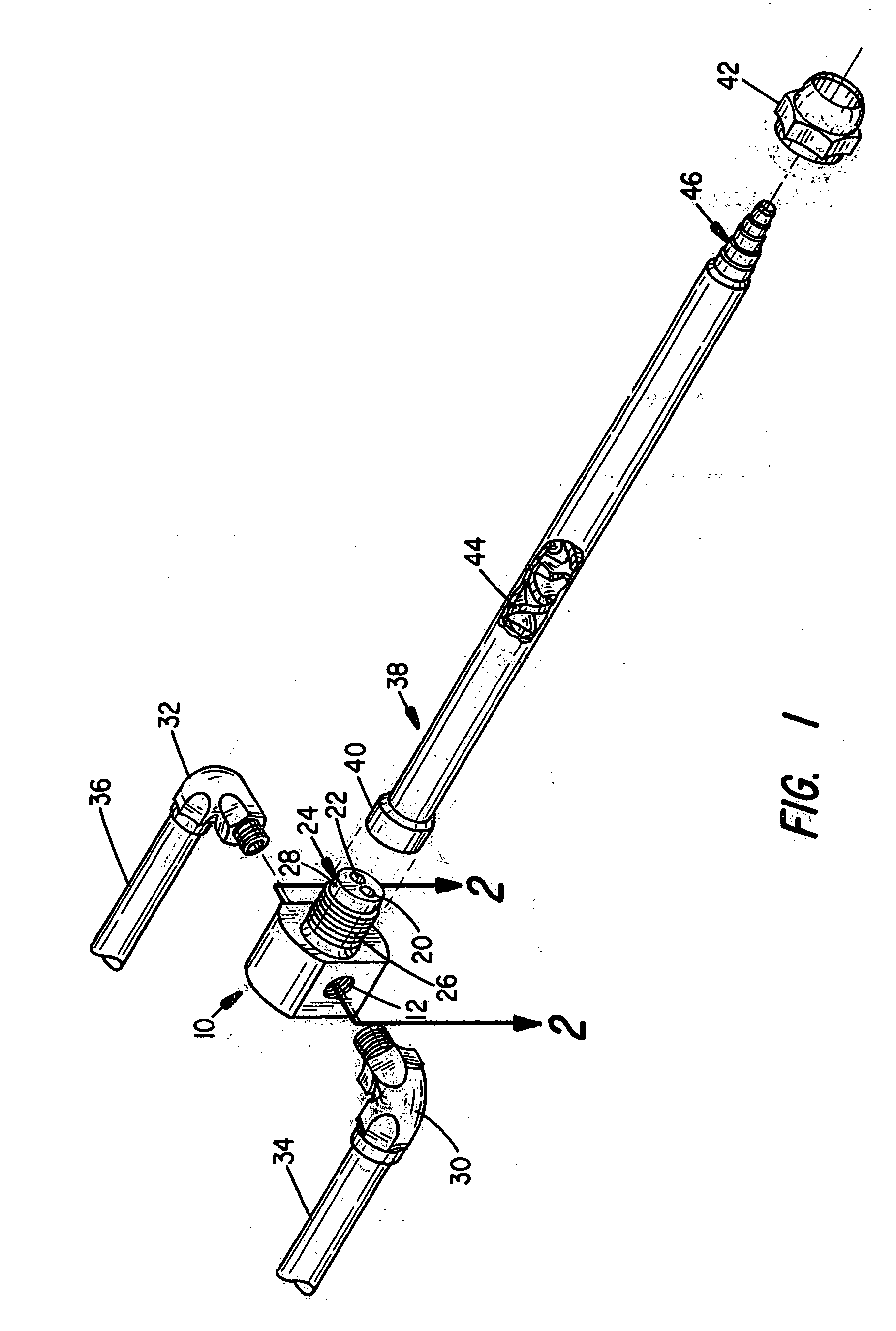

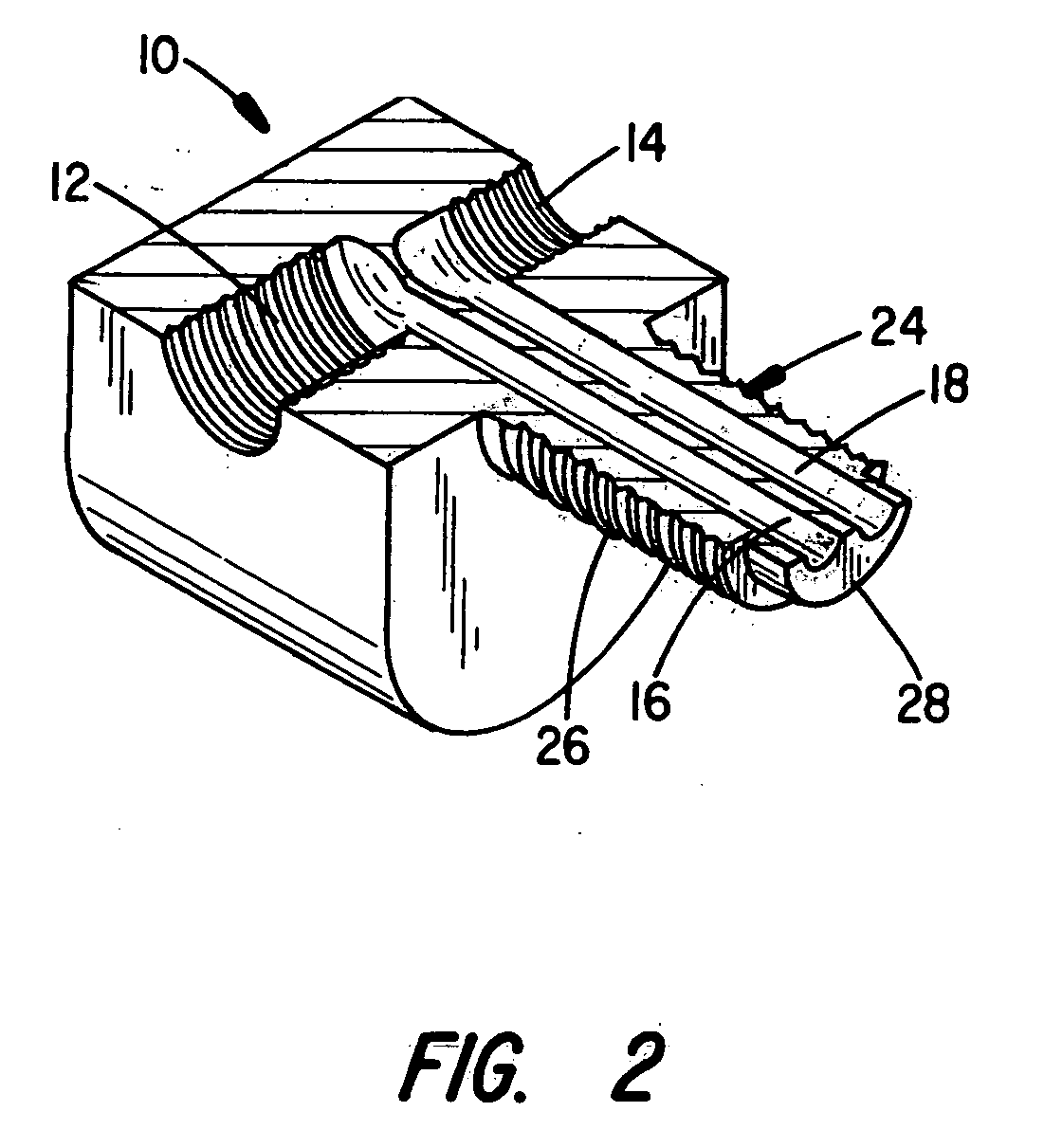

[0014] The detailed description found herein is directed to an example embodiment which discloses the principles of the present invention but is not intended to limit the scope of the inventive concept. Thus, an important aspect of the present invention resides in a proportioning cartridge or valve which can be used to continuously feed separate components for a multi-part curable system. Well known examples include a system for dispensing continuous beads of epoxy resins produced from epichlorohydrin and bisphenol A; and polyurethanes, usually produced by the reaction of a polyfunctional isocyanate combined with a hydroxyl-containing component. The mixing cartridge or valve is combined with and feeds a static mixing applicator nozzle in a manner such that combining of the components and mixing takes place only in the static mixing nozzle and not in the proportioning cartridge or valve. The combination of the mixing valve and a static mixing nozzle provides an applicator for dispens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com