E-Z wire twister

a wire twister and ez technology, applied in the direction of permanent deformation connection, line/current collector details, electrical equipment, etc., can solve the problems of wires not being twisted properly, difficult to properly twist them using two pairs of pliers, and difficulty in method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

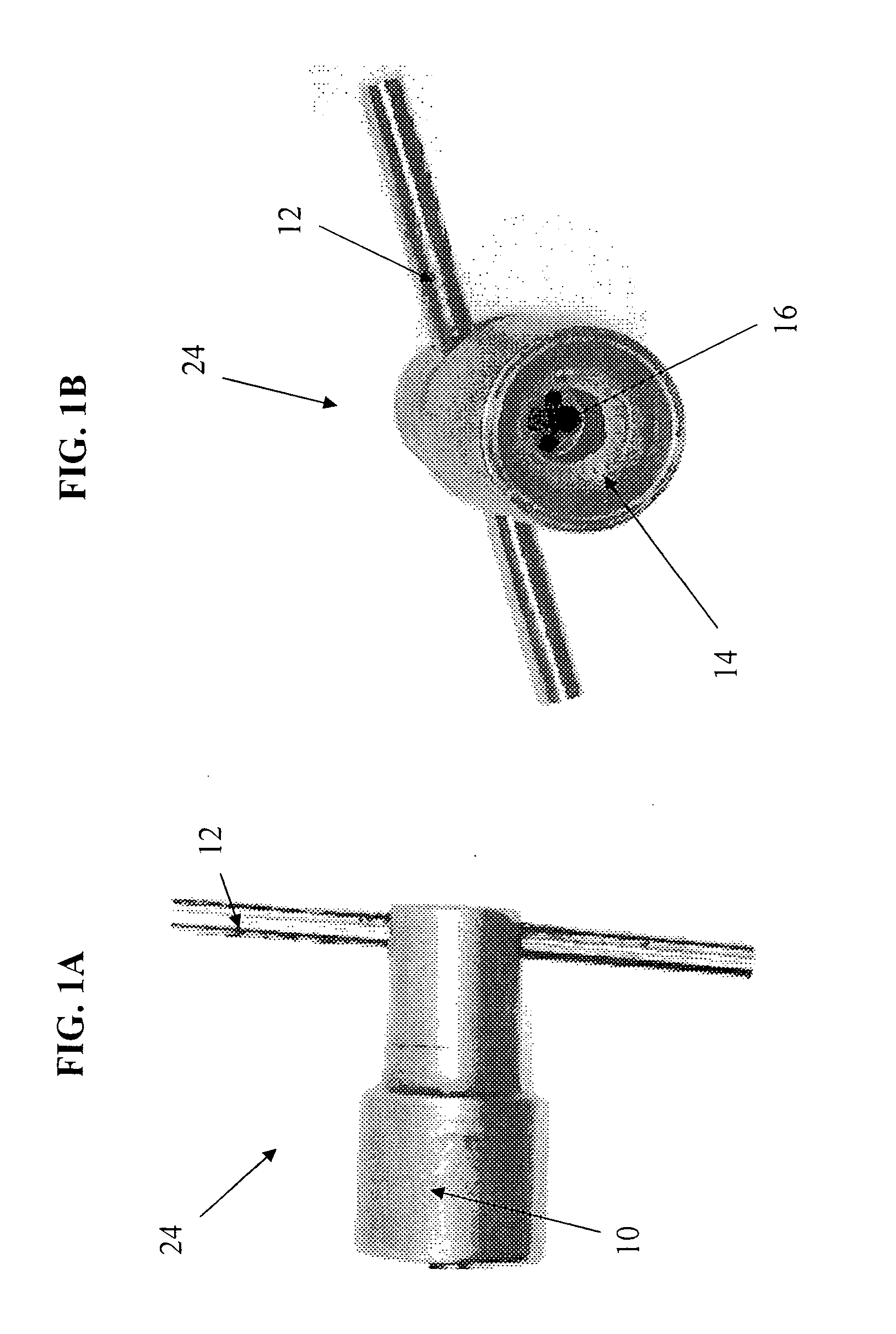

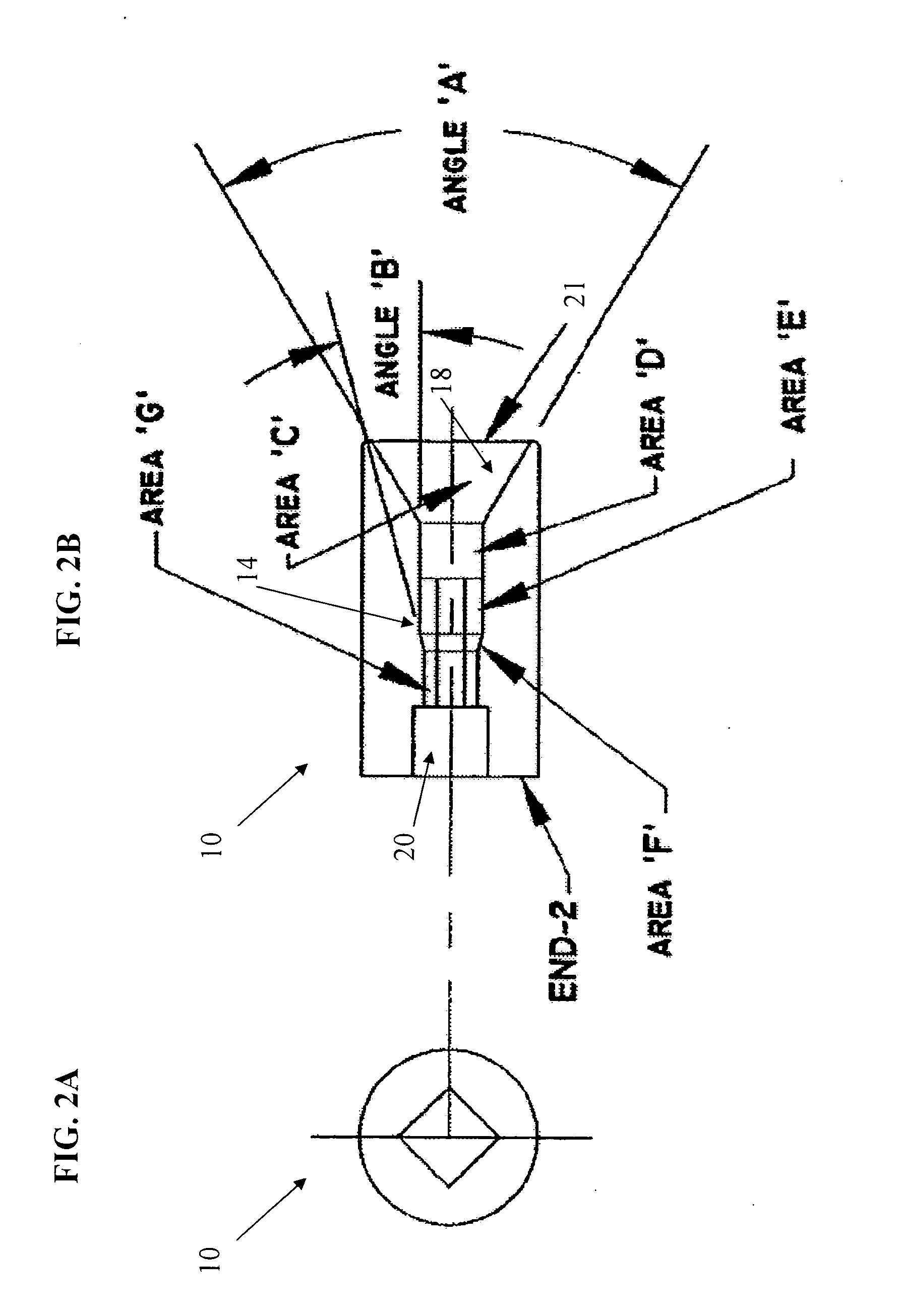

[0025]The present invention is a wire twister used for twisting a plurality of metal or plastic wires together. The wire twister according to the present invention is designed based on a socket concept, similar to a mechanical socket tool. As depicted in FIGS. 1A and 1B, the wire twister or tool 24 comprises a twister head or body portion 10 and a twister rod or gripping portion 12. The twister rod 12 can be inserted into the twister head 10 such that it is substantially perpendicular to the twister head 10. Other means for twisting the head 10 may be utilized if suitable for the purpose. For example a ratchet device may be used and inserted into a standard type ratchet opening as shown in FIG. 2A.

[0026]A cavity 14 inside the twister head 10 is specifically designed to receive the wires and re-arrange them prior to twisting. FIG. 1B, which is a front view of the twister head 10 of tool 24 of the present invention and shows the cavity 14 consisting of several stages of intersecting c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com