Paper feed cassette

a cassette and paper technology, applied in the field of paper feed cassettes, can solve the problems of disadvantageous likely to be curved (warped) at the center of the width direction, disadvantageous likely to be carried in a direction, etc., and achieve the effect of suppressing curvature (warpage) and inhibiting the increase of the number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

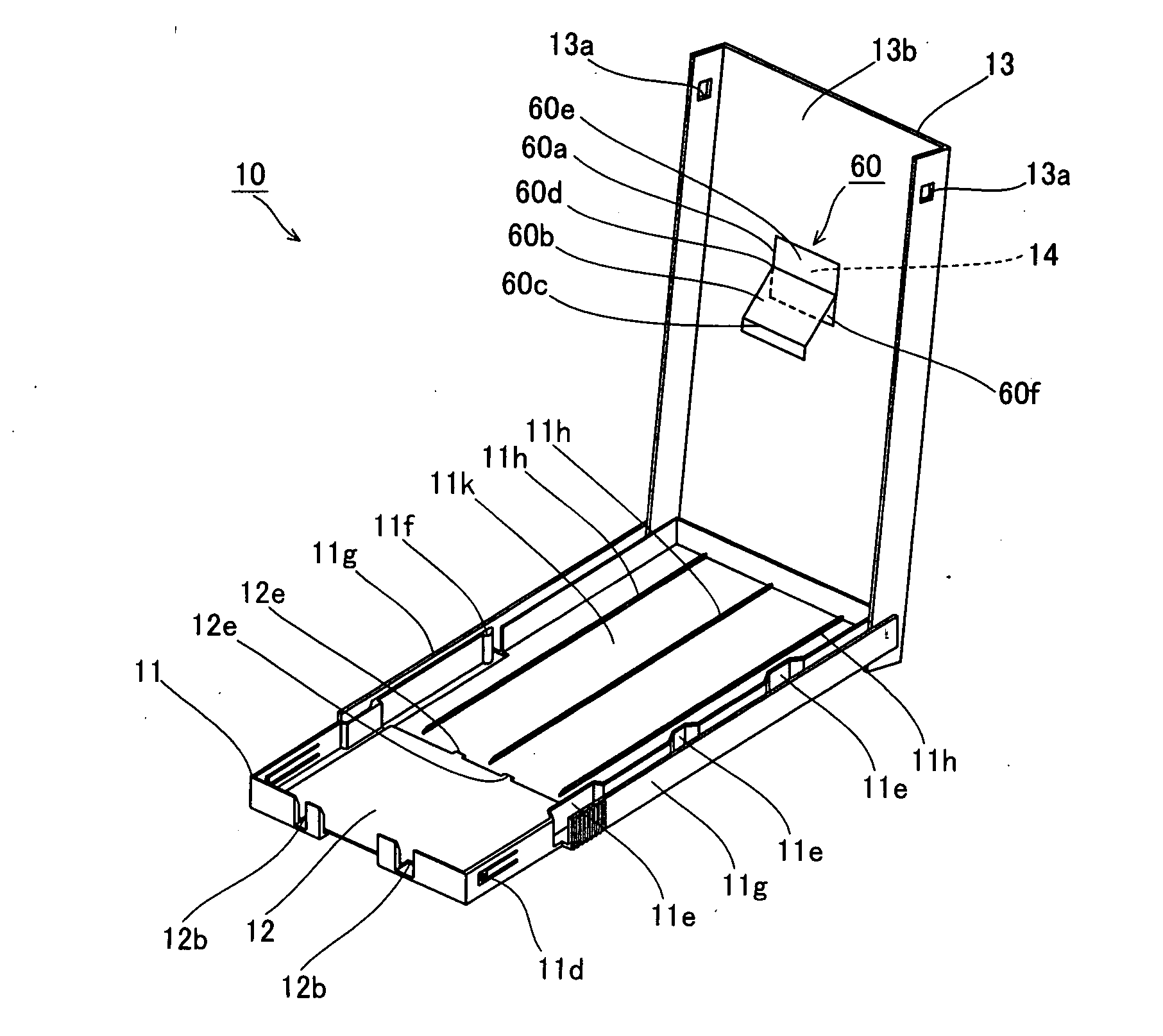

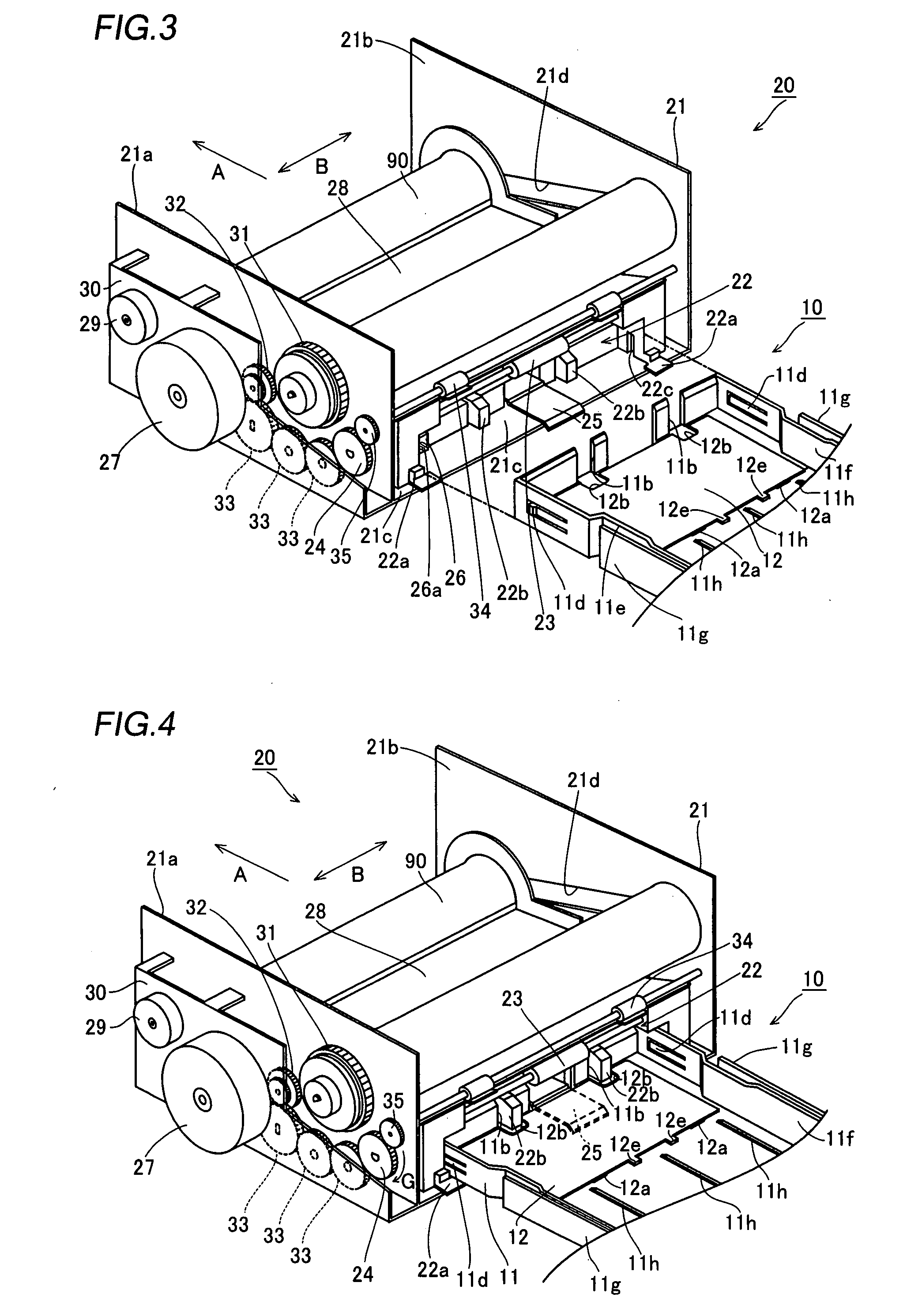

[0061]With reference to FIGS. 1 to 10, a structure of a paper feed cassette according to a first embodiment of the present invention will be now described. According to the embodiment, the present invention is applied to the paper feed cassette of a dye sublimation printer which is an exemplary image generating apparatus.

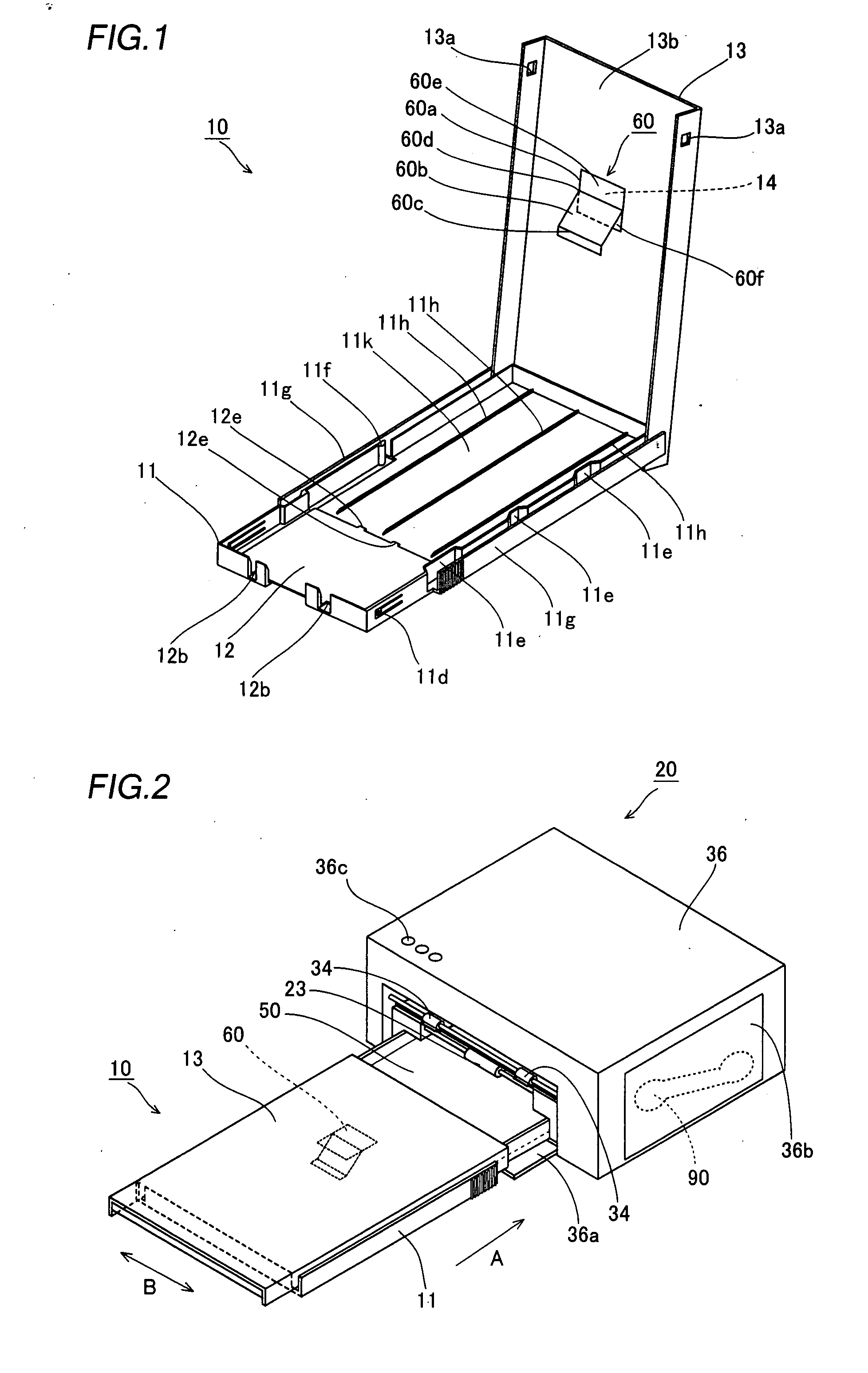

[0062]A paper feed cassette 10 according to the first embodiment of the present invention is so formed as to be detachably mounted on a dye sublimation printer 20 as shown in FIG. 2.

[0063]The paper feed cassette 10 comprises a cassette body 11 made of resin, a lift member 12 made of resin and a lid member 13 made of resin as shown in FIGS. 1 and 2. The lid member 13 made of resin is provided for inhibiting dust or the like from adhering to papers 50 and slidably mounted on the cassette body 11 as shown in FIG. 2. As shown in FIGS. 3 to 7, the cassette body 11 has a pair of engaging portions 11a (see FIG. 5) rotatably engaged with the lift member 12, a pair of notche...

second embodiment

[0098]A second press member 70 according to a second embodiment has a different structure from that of the first embodiment with reference to FIGS. 16 to 19. Structures other than the second press member 70 according to the second embodiment are similar to those according to the aforementioned first embodiment, and hence the description thereof will not be repeated.

[0099]According to the second embodiment, a second press member 70 made of resin pressing an upper surface of papers 50 is provided on a lower surface 13b of a lid member 13 independently of the lid member 13 as shown in FIG. 18. As shown in FIG. 16, a flat portion 70a of the second press member 70 includes a first flat portion 71a on the right and a second flat portion 71b on the left, between which a bonding line of the flat potion 70a and the inclined portion 70b is a boundary line. The second flat portion 71b is provided with a U-shaped cutout portion 70e in a prescribed region of a bonding portion 70d between the fir...

third embodiment

[0106]With reference to FIGS. 23 to 26, according to a third embodiment, an inclined portion 80b of the second press member 80 is supported by a support portion 80f dissimilarly to the aforementioned first and second embodiments. Structures other than the second press member 80 according to the third embodiment are similar to those according to the aforementioned first embodiment, and hence the description thereof will not be repeated.

[0107]In a paper feed cassette 10 according to the third embodiment, a second press member 80 made of resin pressing an upper surface of papers 50 is provided on a lower surface 13b of a lid member 13 independently of the lid member 13 as shown in FIG. 25. The second press member 80 includes the support portion 80f integrally bonded with a first flat portion 81a on an end on a lower surface of the first flat portion 81a, extending a direction oblique to the inclined portion 80b and bonding with the inclined portion 80b. The support portion 80f supports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com