Food Sachet or Container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

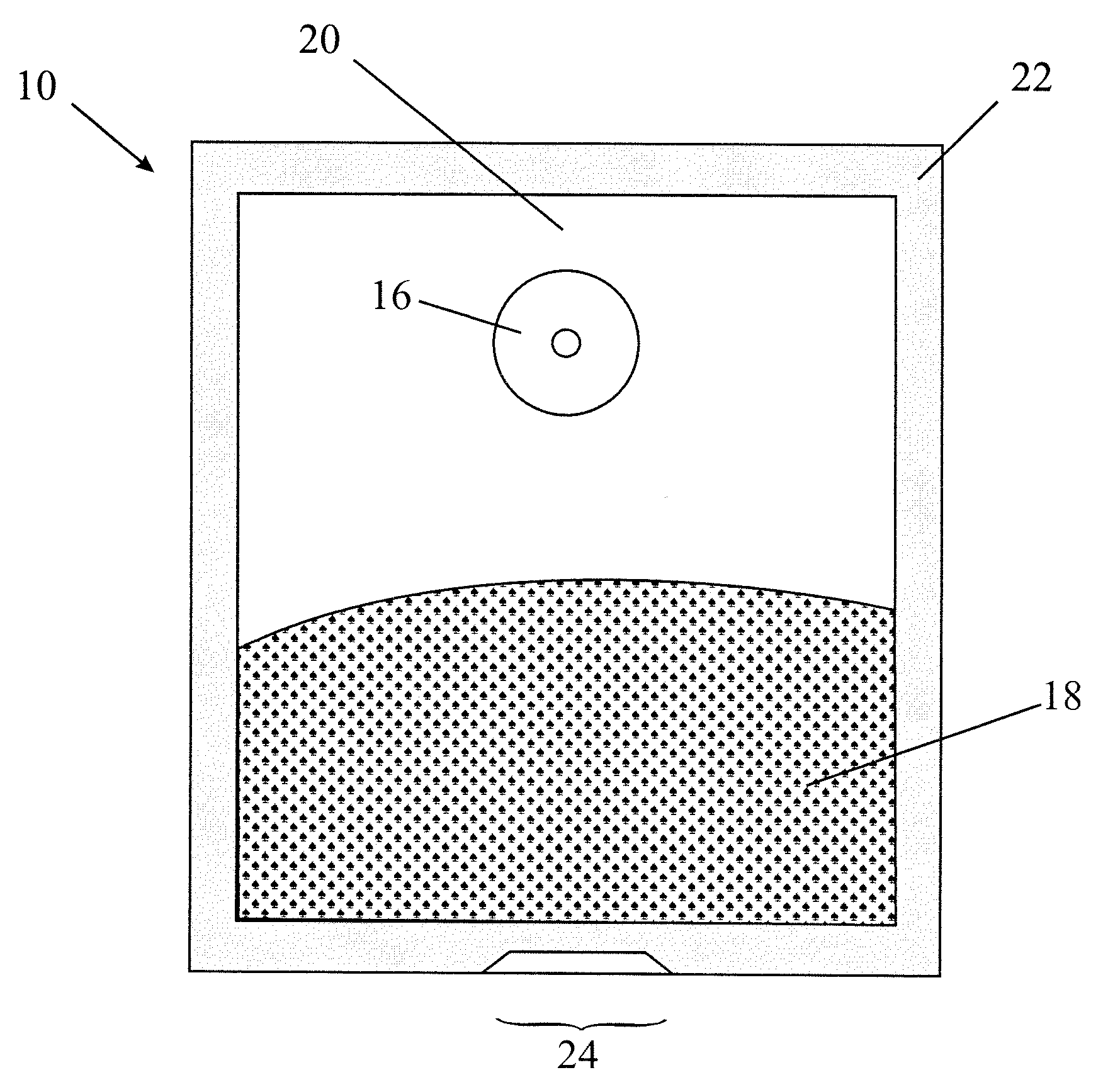

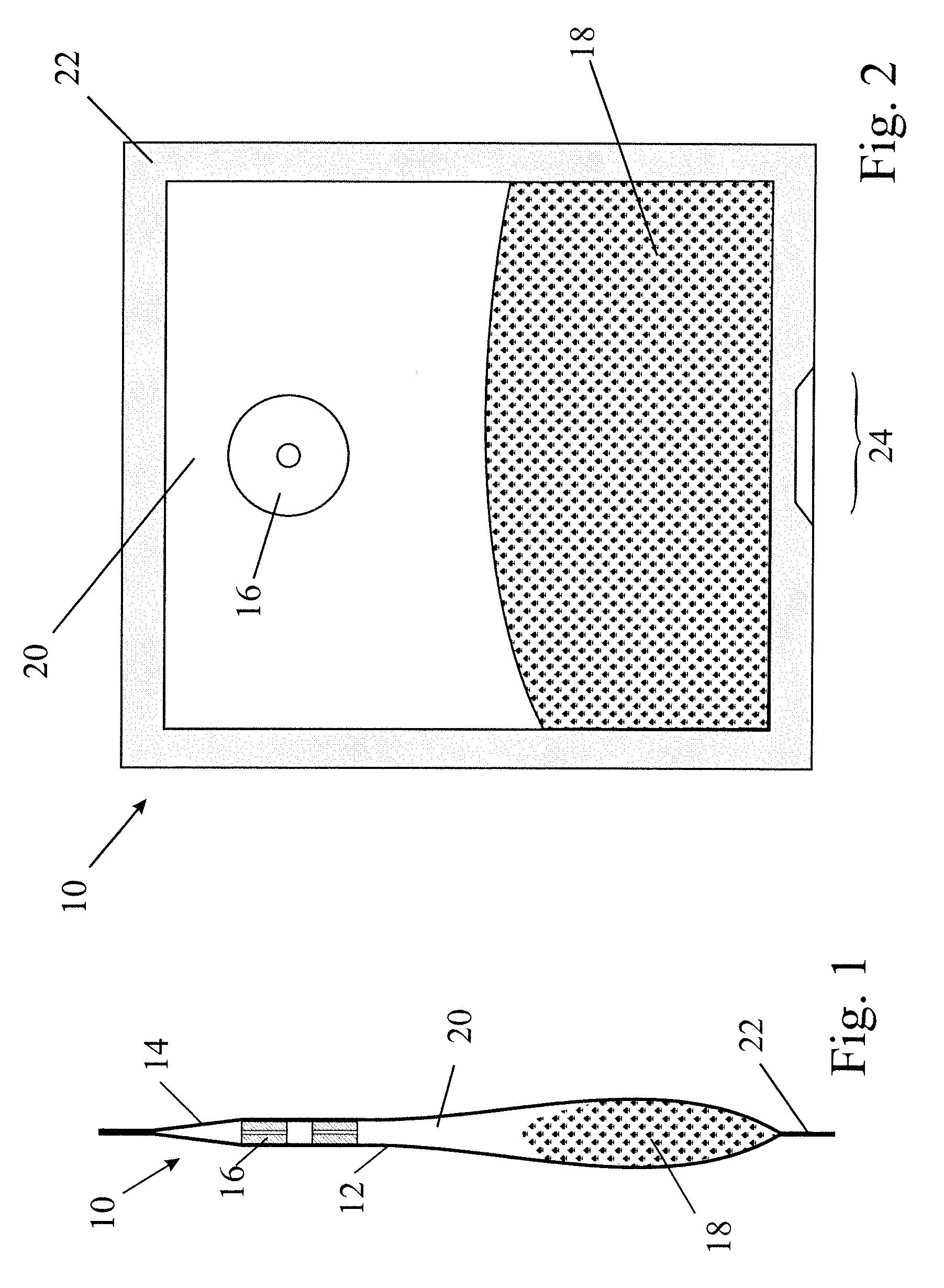

[0023] The sachet 10 shown in the drawings is essentially the same as that disclosed in WO2004 / 019741 to which reference may be made for a more detailed explanation of the sachet and the manner in which it is used in a beverage dispensing machine. The sachet 10 is formed of two plastics sheets 12, 14 welded to one another along seams 22 to define a sealed pocket 20 filled with a granular beverage material 18, such as ground coffee, tea leaves, or chocolate or soup powder.

[0024] A spacer 16 is provided to keep the two sheets 12, 14 apart and hot water injected into the spacer 16 passes into the pocket 20 through radial passages in the spacer 16 and contacts the powder 18. The spacer 16 is designed to prevent the brewed beverage from contacting the needle that injects hot water into the sachet to prevent contamination of the needle. As the pocket 20 fills with hot water, the pressure in the pocket rises until a point is reached when a weak seal region 24 along the seam 22 ruptures an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com