Resilient two stage clip for automotive application

a two-stage clip and automotive technology, applied in the direction of snap fasteners, buckles, mechanical devices, etc., can solve the problem of insufficient force of air curtain deploymen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

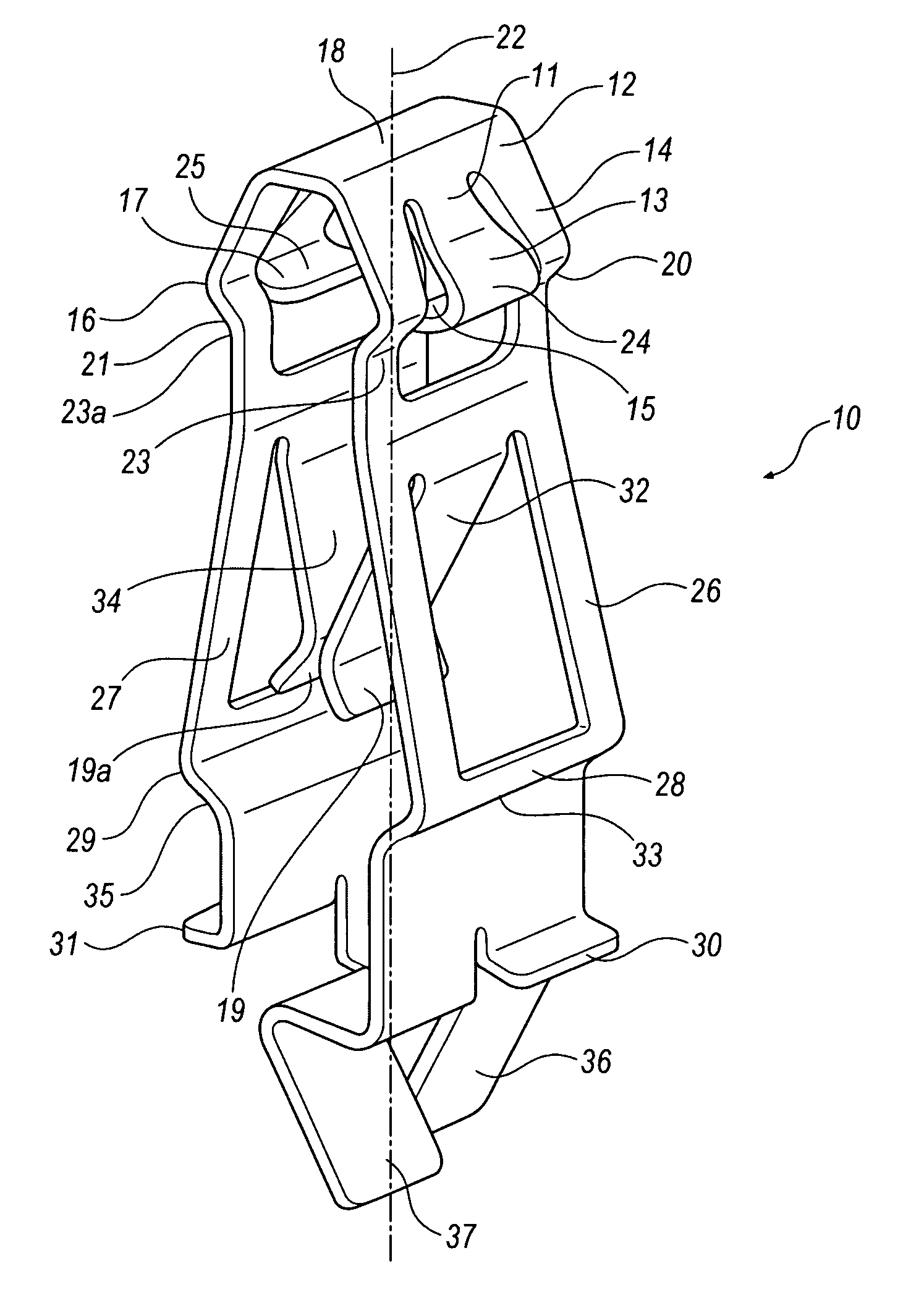

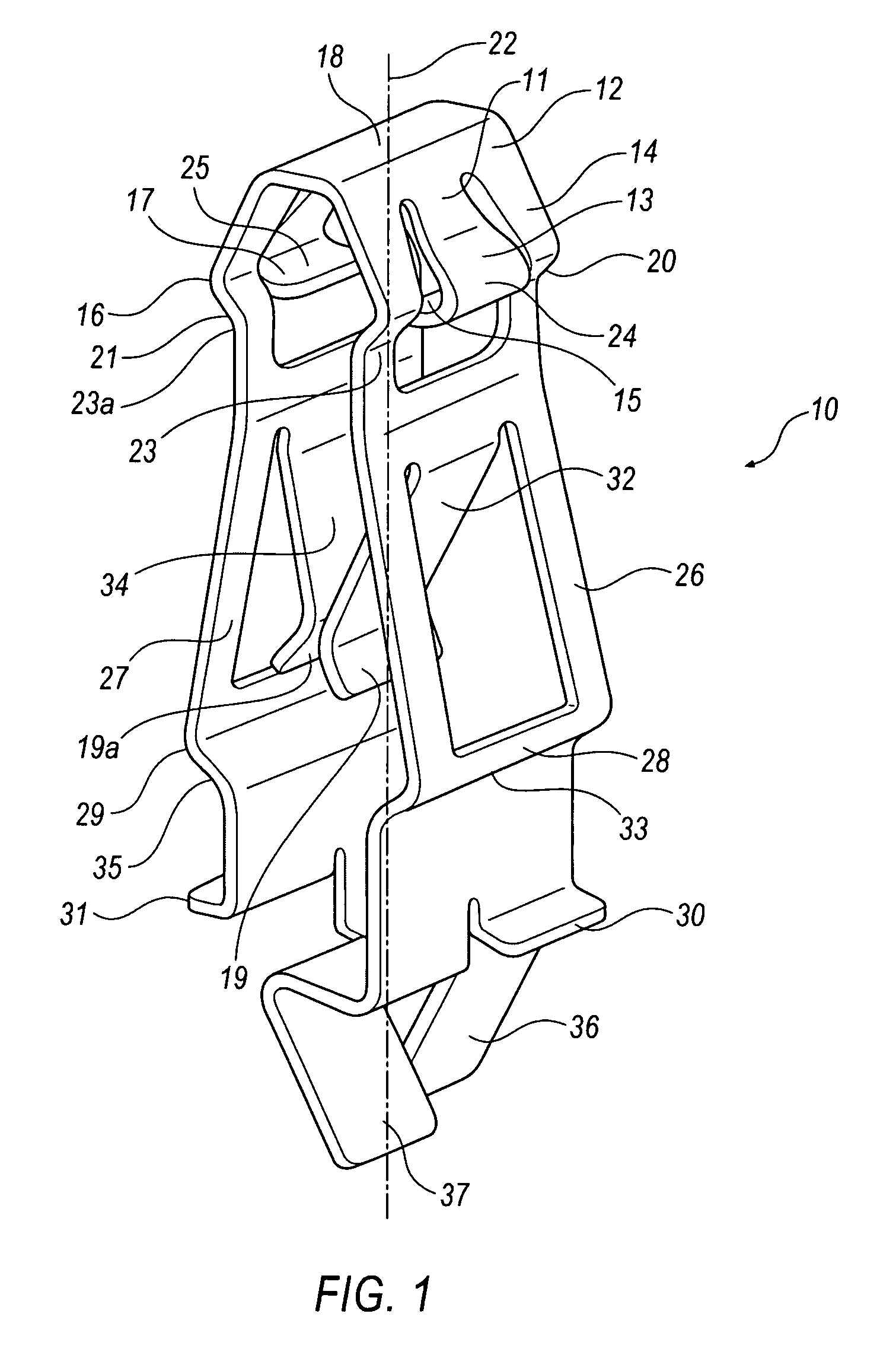

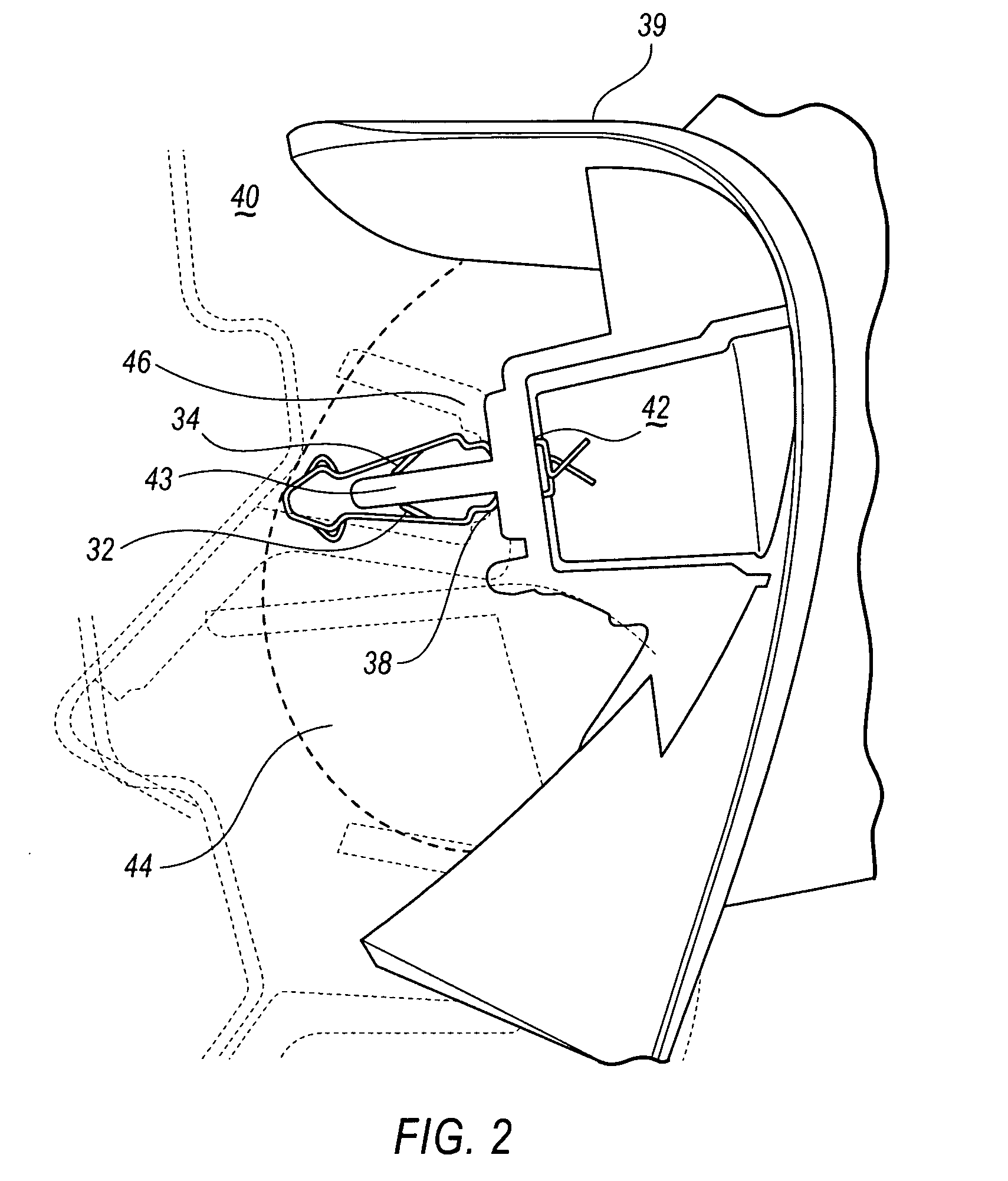

[0011]Turning now to the drawings wherein like numerals refer to like structures, and particularly to FIG. 1, there is shown therein a perspective view of two stage retaining spring clip 10. Clip 10 is constructed in one piece and may be made of a resilient material such as metal, such as steel or any other metal, or plastic or any other resilient material to present a unitary structure.

[0012]The clip of FIG. 1 is equipped with an insert nose portion 12 having angled portions 14 and 16 that terminate in shoulder portions 20 and 21 respectively to form a first retaining portion 18. Shoulders 20, 21 terminating in base 23 and 23a, respectively extend at a first angle that is shown as obtuse to the centerline 22 of the two stage retaining spring clip 10, but which may be perpendicular to the centerline, or at any other angle according to the design requirements of the trim panels to be fastened together. Angled portions 14 and 16 of the insert nose portion may be equipped with optiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com