Printer-plotter and method for printing and cutting

a printing and cutting technology, applied in the field of printing and cutting, can solve the problems of increased size and cost of the apparatus, contaminated cutting head, operation error of the cutting head,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

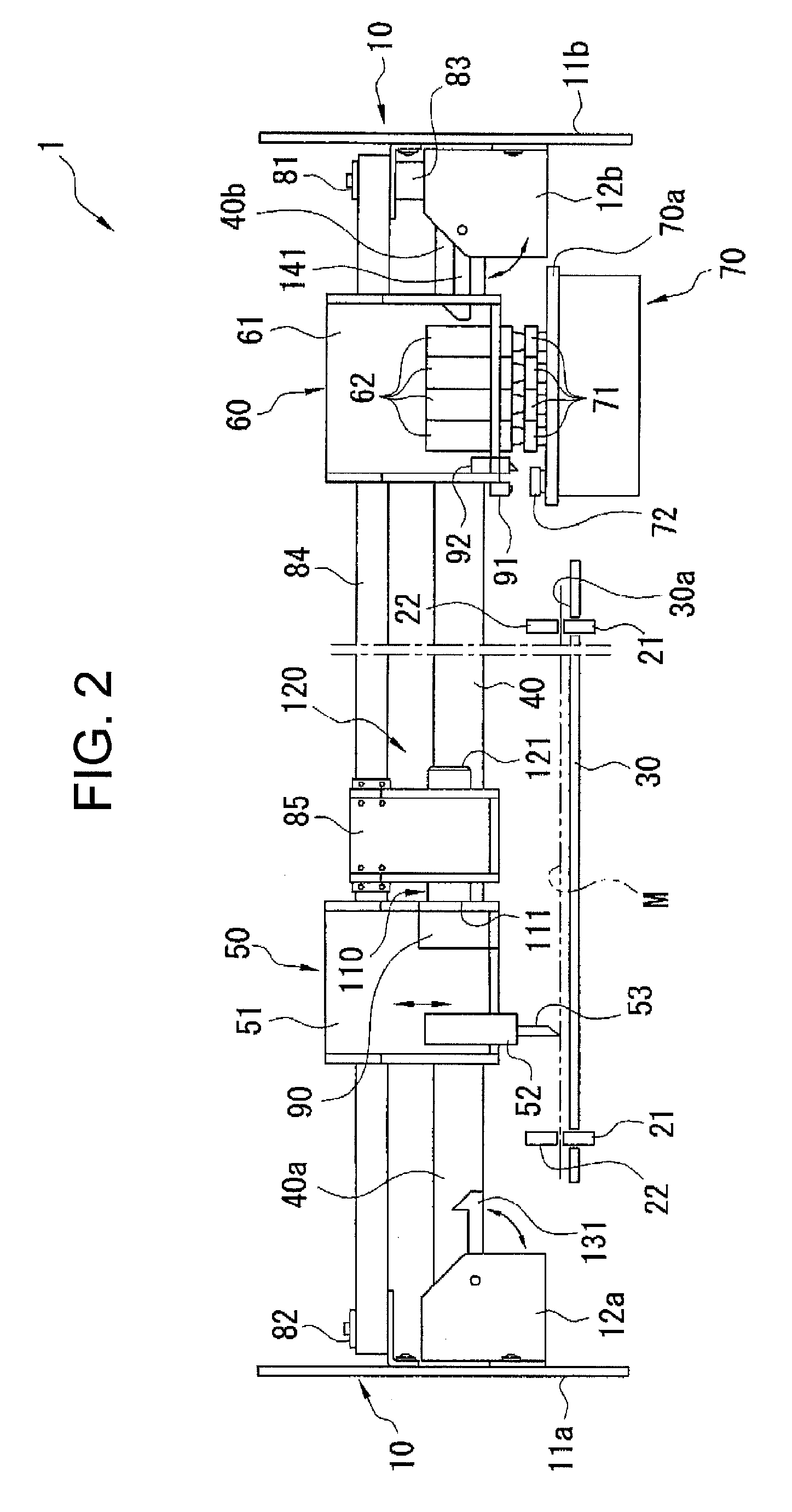

[0026]The embodiments will now be described with reference to the accompanying drawings, wherein like reference numerals designate corresponding or identical elements throughout the various drawings. It should be noted that the directions of arrows F, R, U marked in the drawings are forward, rightward, upward in the following description, respectively.

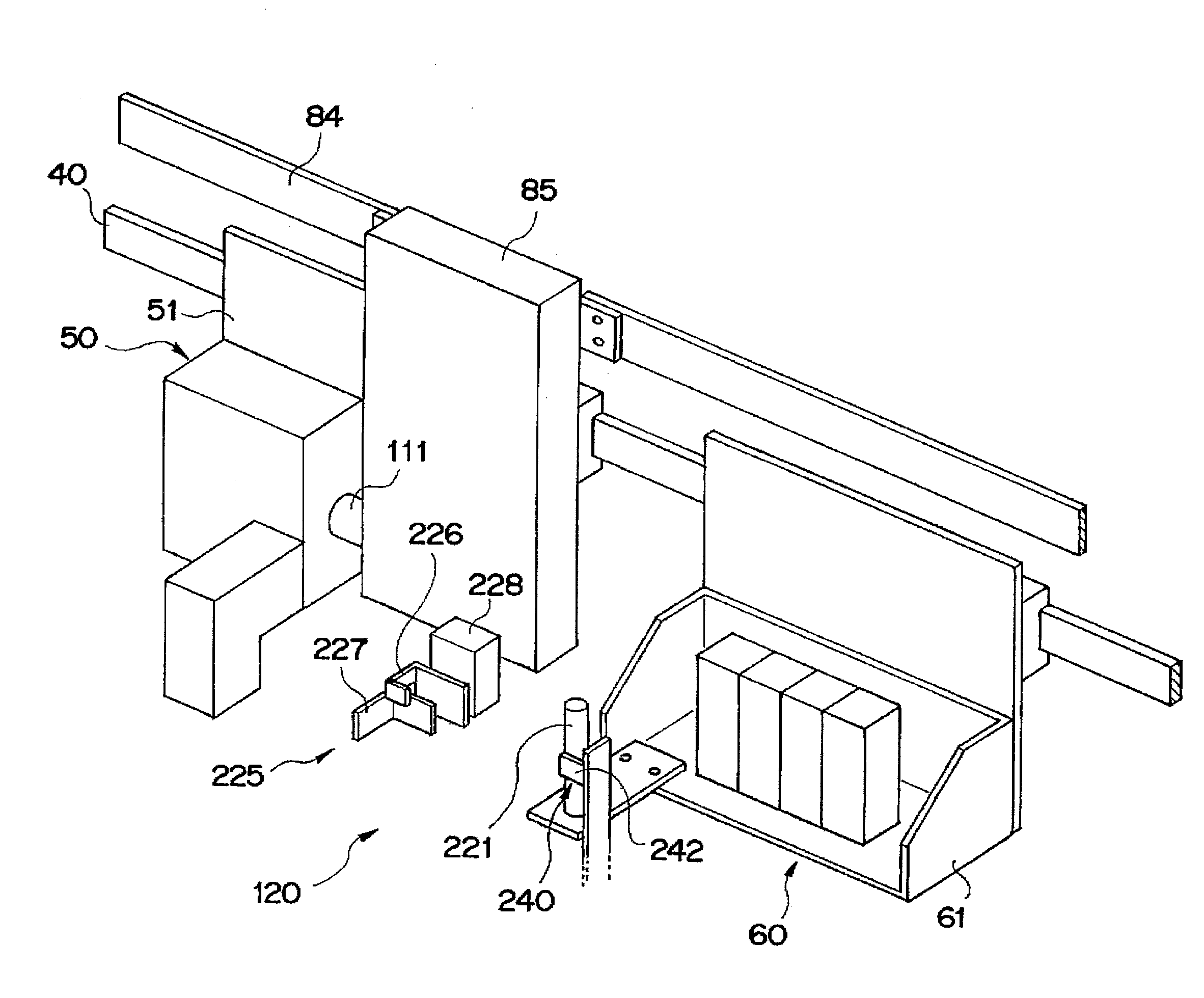

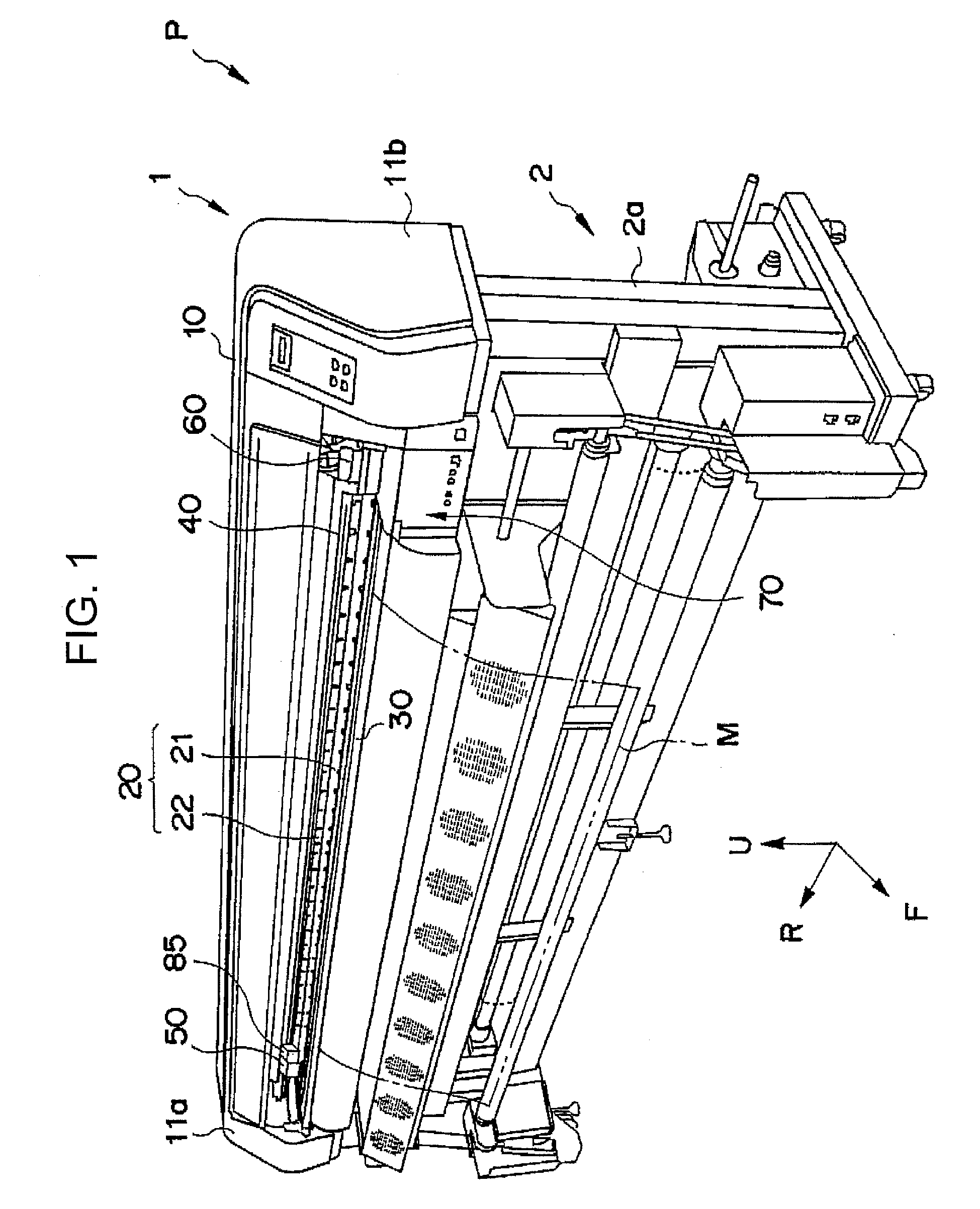

[0027]A printer-plotter of which entire appearance is shown in FIG. 1 includes a main unit 1 for conducting a predetermined action such as printing to a sheet-like medium M such as a roll of paper and a supporting unit 2 having a pair of right and left legs 2a by which the main unit 1 is supported. The main unit 1 includes a body 10 fixed to the upper ends of the legs 2a, a feeding mechanism 20 for feeding the sheet-like medium M in the anteroposterior direction, a platen 30 for supporting the sheet-like medium M, a guide rail 40 extending in the lateral direction above the platen 30, a cutting head 50 and an inkjet head 60 which are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com