Printer-plotter

A head unit and medium technology, applied in printing devices, inking devices, printing, etc., can solve the problems of head unit enlargement, hindering high-speed printing, etc., and achieve the effect of improving printing speed and cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

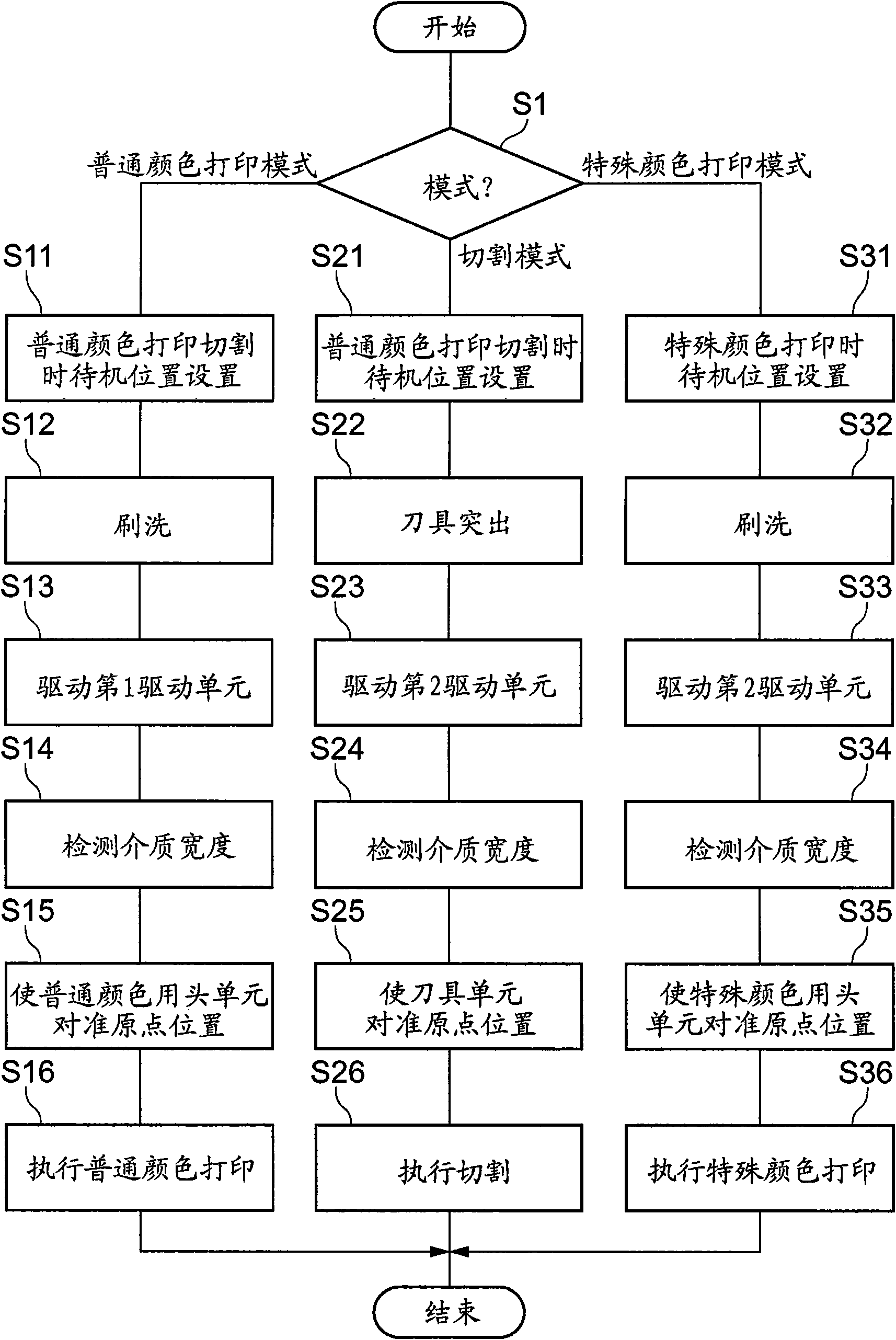

[0028] Next, preferred embodiments of the printing and plotting device of the present invention will be described in detail with reference to the accompanying drawings. In addition, in all drawings, the same code|symbol is attached|subjected to the same or corresponding part.

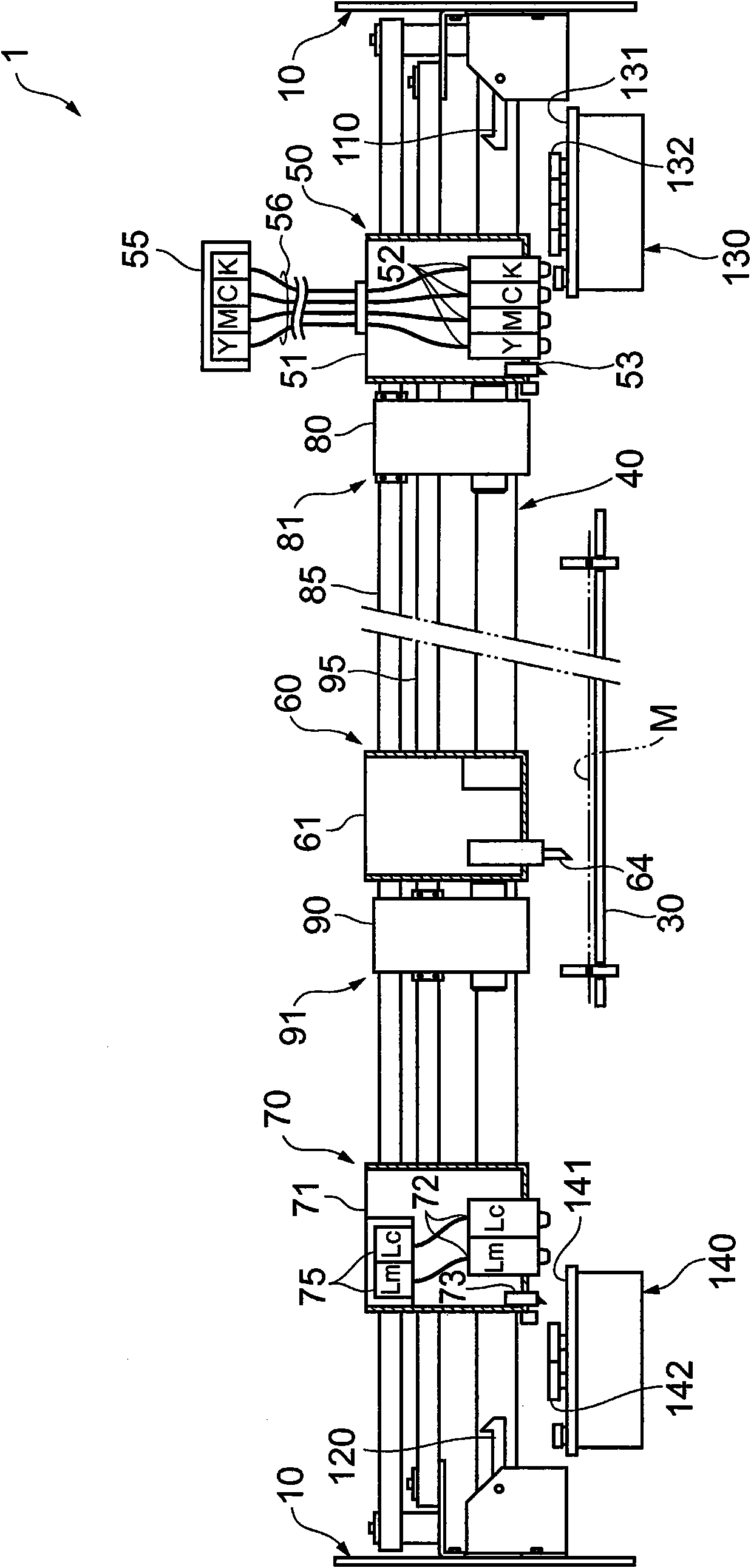

[0029] figure 1 It is a partial enlarged view of the printer and plotter of this embodiment. The printer 1 of the present embodiment prints an image on the medium M placed on the platen 30 and cuts the medium M. Such as figure 1 As shown, on the main body 10 of the printing and plotting device 1 , above the platen 30 supporting the medium M, a guide rail 40 extending along the extending direction of the platen 30 is fixed.

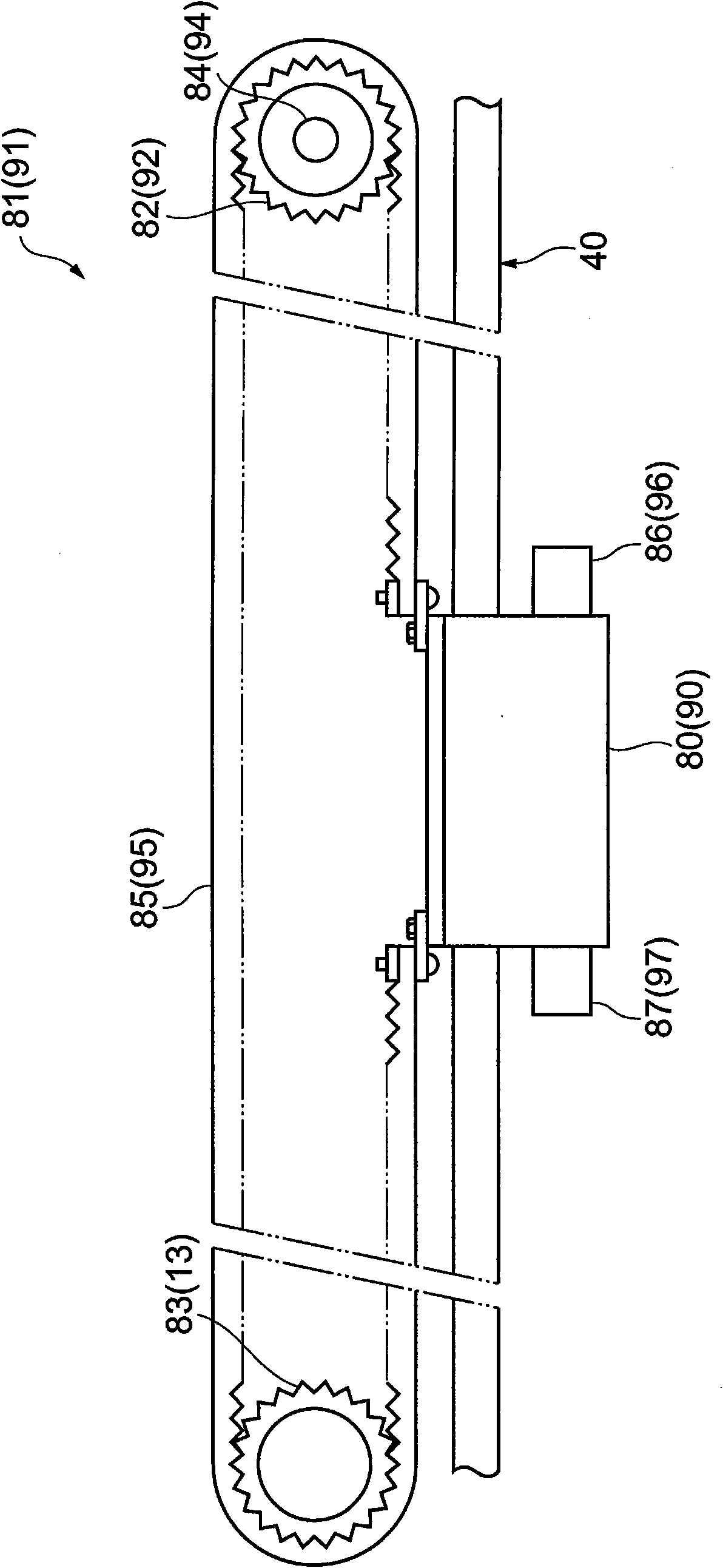

[0030] On the guide rail 40 , a head unit 50 for a normal color, a cutter unit 60 , and a head unit 70 for a special color are slidably supported in this order from the end. In addition, in the following description, the approaching or departing direction of the platen 30 relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com