Protecting structure for movable mechanism in a miniature lens

a technology of movable mechanism and protective structure, which is applied in the direction of mountings, optics, instruments, etc., can solve the problems of lens damage, lens becoming damaged or useless, lens just cannot afford to fall, etc., and achieve the effect of limiting the torsion force and limiting the elastic rang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

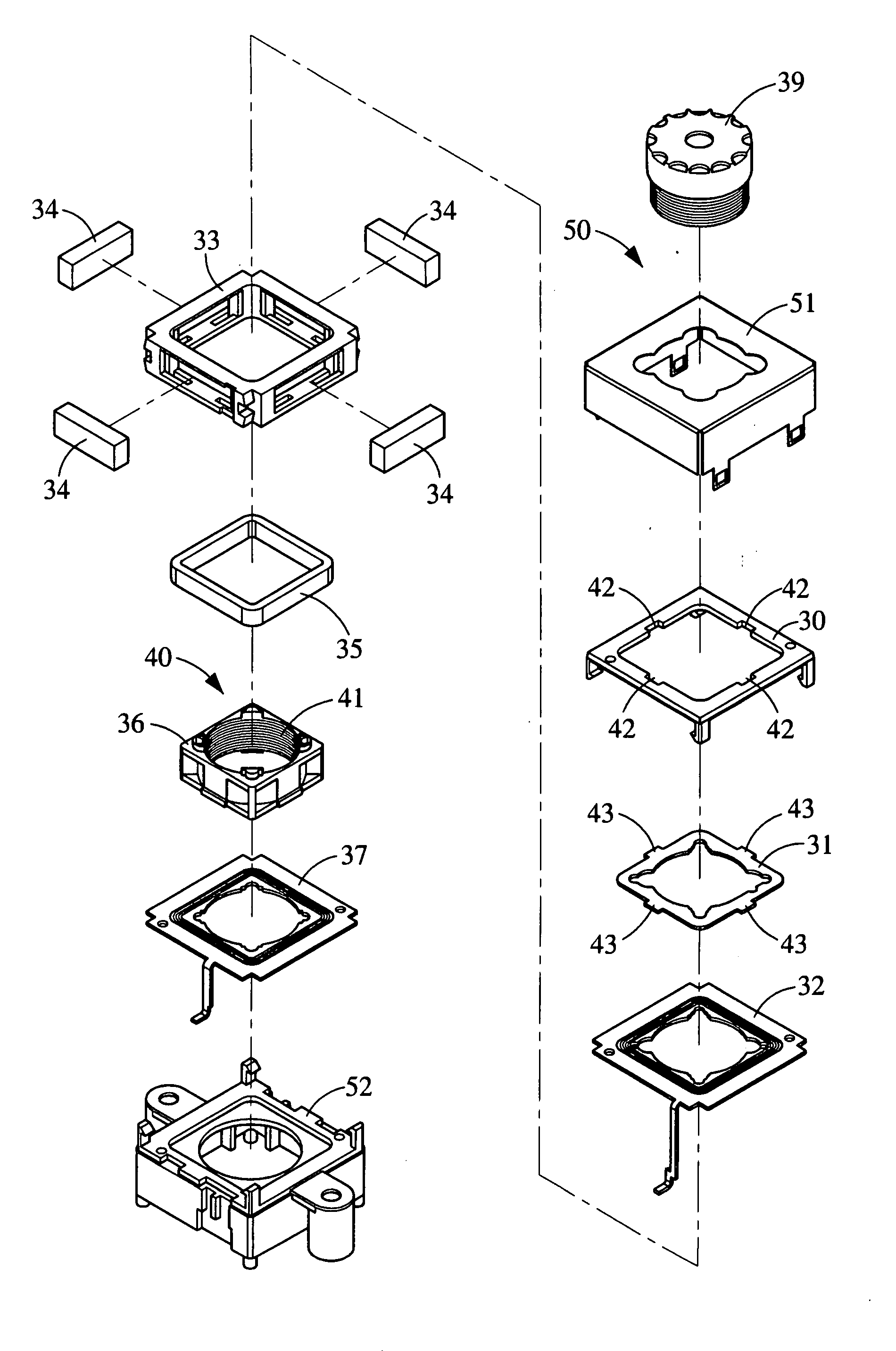

[0016]Please refer to FIG. 3 that is an exploded perspective view of a protecting structure for movable mechanism in a miniature lens according to the present invention mounted in a housing 50 of a focusing mechanism of the miniature lens. The housing 50 consists of an upper case 51 and a base 52, and the present invention is received in the upper case 51. As shown, the protecting structure of the present invention includes an upper cover 30, a protective member 31, a first elastic member 32, a frame 33, a plurality of magnetic elements 34, a winding 35, a lens holder 36, and a second elastic member 37. The lens holder 36 is a hollow ring member defining a through hole 40, on a peripheral wall thereof screw threads 41 are provided, so that a lens 39 may be correspondingly screwed into the lens holder 36.

[0017]FIG. 4 is an assembled perspective view of FIG. 3 with the lens 39 and the upper case 51 omitted therefrom. As shown, the upper cover 30 defines a central opening, along a peri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com