Panel

a technology of composite cladding and panels, applied in the field of composite cladding panels, can solve the problem that panels can be often uninteresting aesthetically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

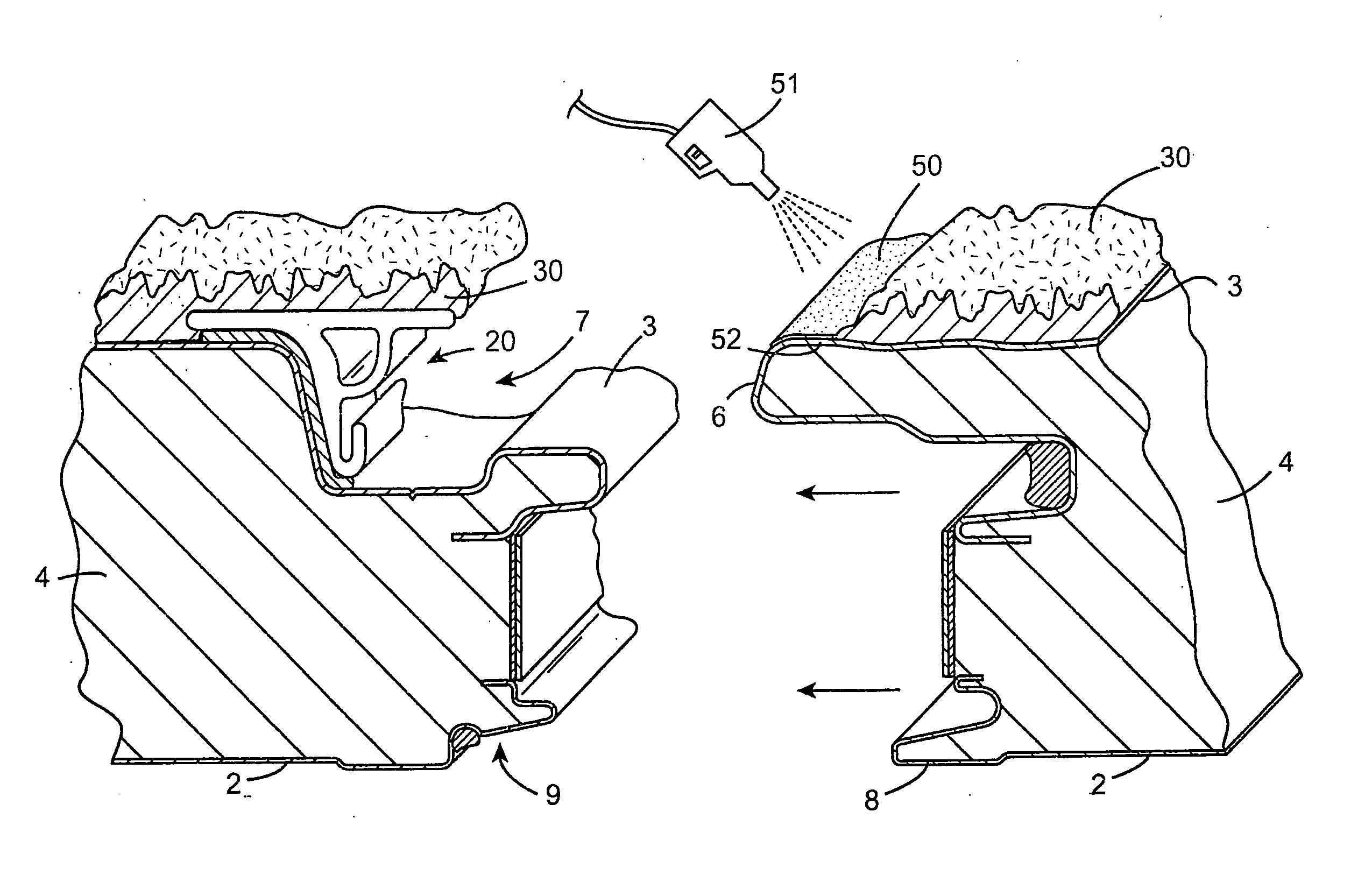

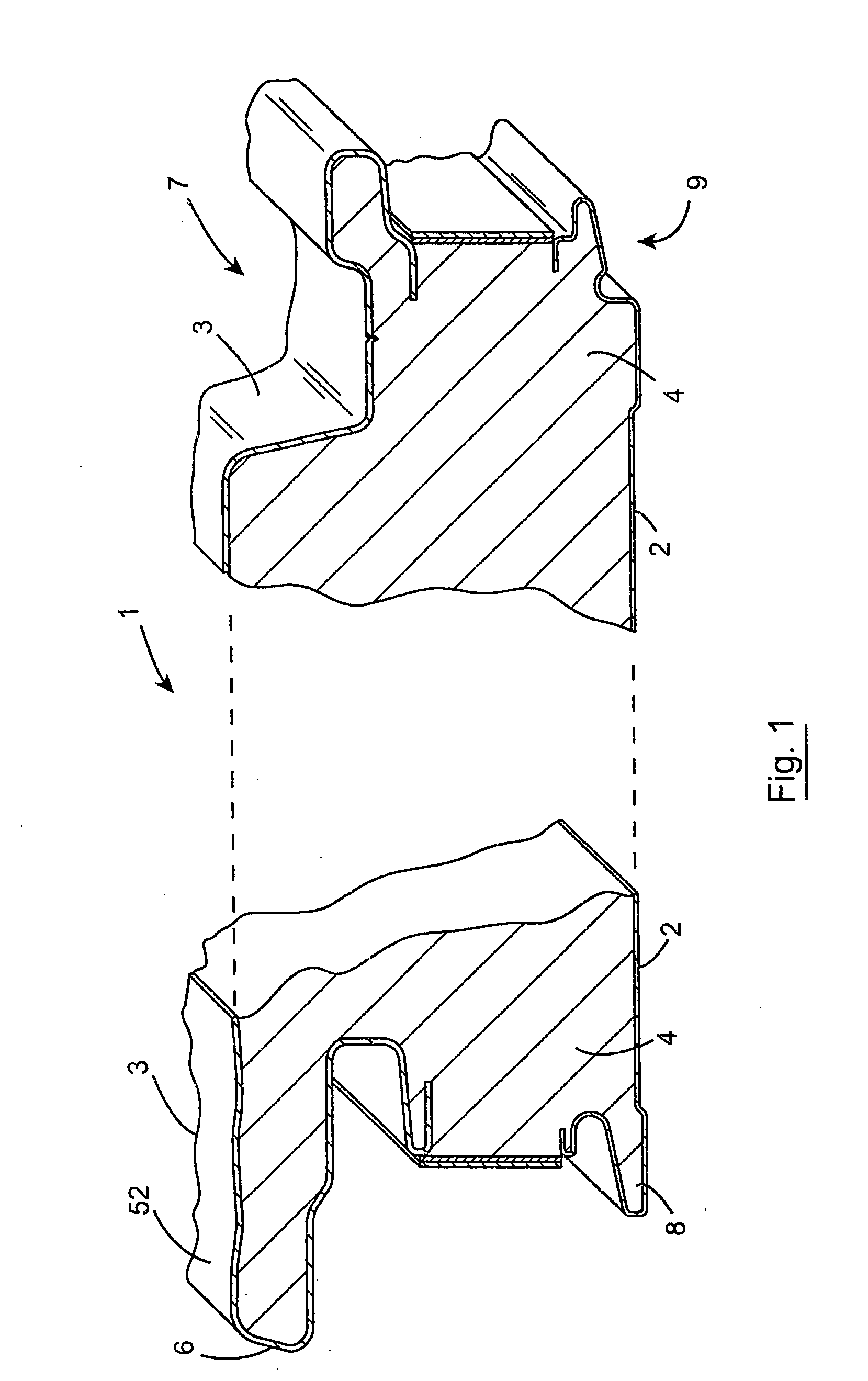

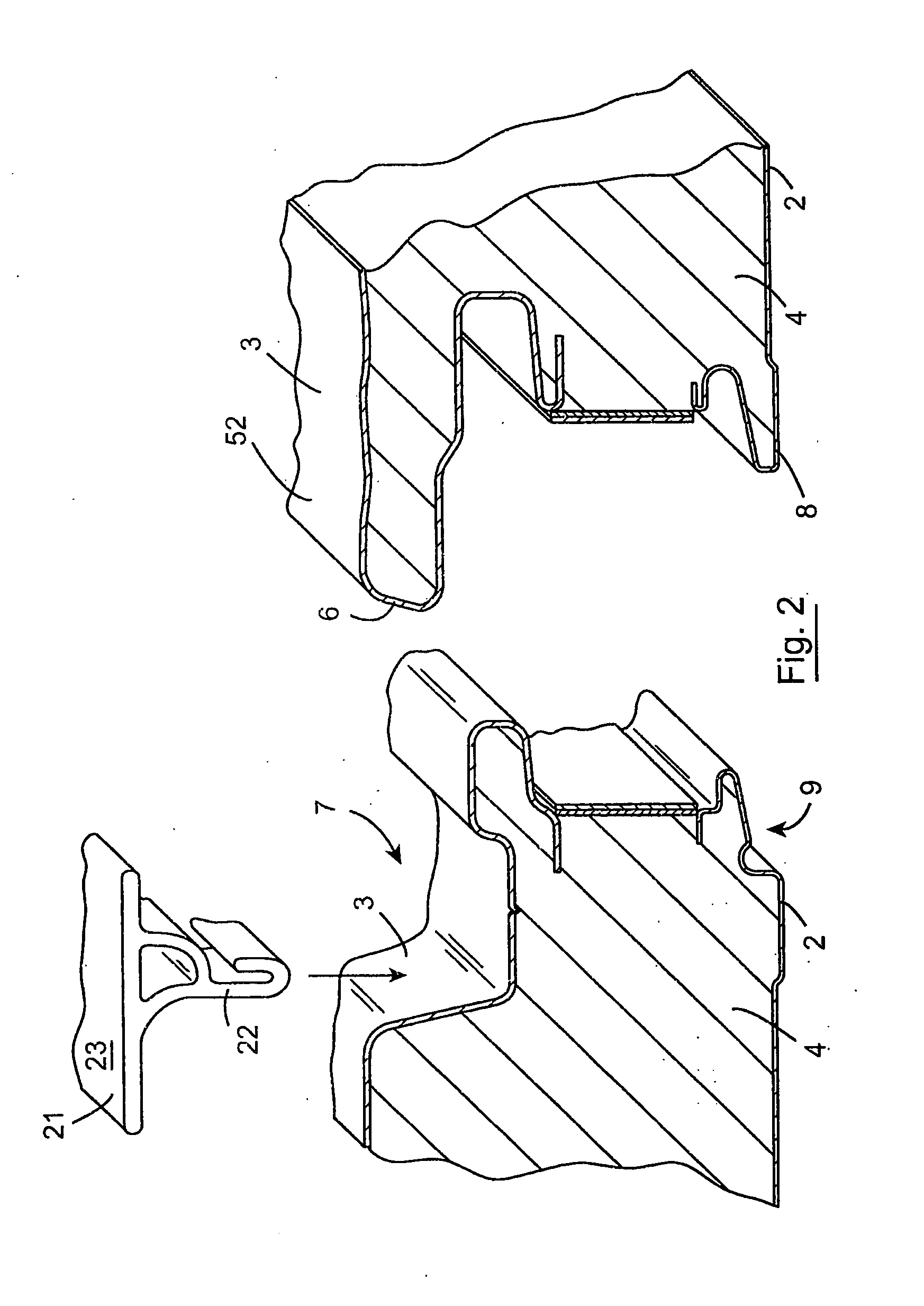

[0023]Referring to the drawings and initially to FIG. 1 there is illustrated a composite cladding panel 1. The panel 1 comprises a skin or backing tray 2 which is usually of steel and an external skin 3 which is also usually of steel with a layer of foam insulation material 4 such as a phenolic or polyurethane based foam material therebetween. The panel may be of any suitable type such as that described in our UK 2325678A.

[0024]The panel has formations along both side edges. The formations are profiled so that one side edge of a panel is interengagable, on assembly, with the opposite side edge of an adjacent panel. Thus, the external skin 3 is profiled to define a male projecting part 6 along one side and a corresponding recess 7 along the opposite side. Similarly the internal skin 2 is profiled to define a male projecting part 8 along one side and a corresponding recess 9 along the opposite side. Various seals may be provided at the joint.

[0025]In the invention, a pre-formed gasket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com