Kirschner wire clamp

a wire clamp and wire technology, applied in the field can solve the problems of limited functionality, difficult handling of kirschner wire clamps known from prior art, and difficulty in carrying out satisfactory preliminary fixation of bone plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

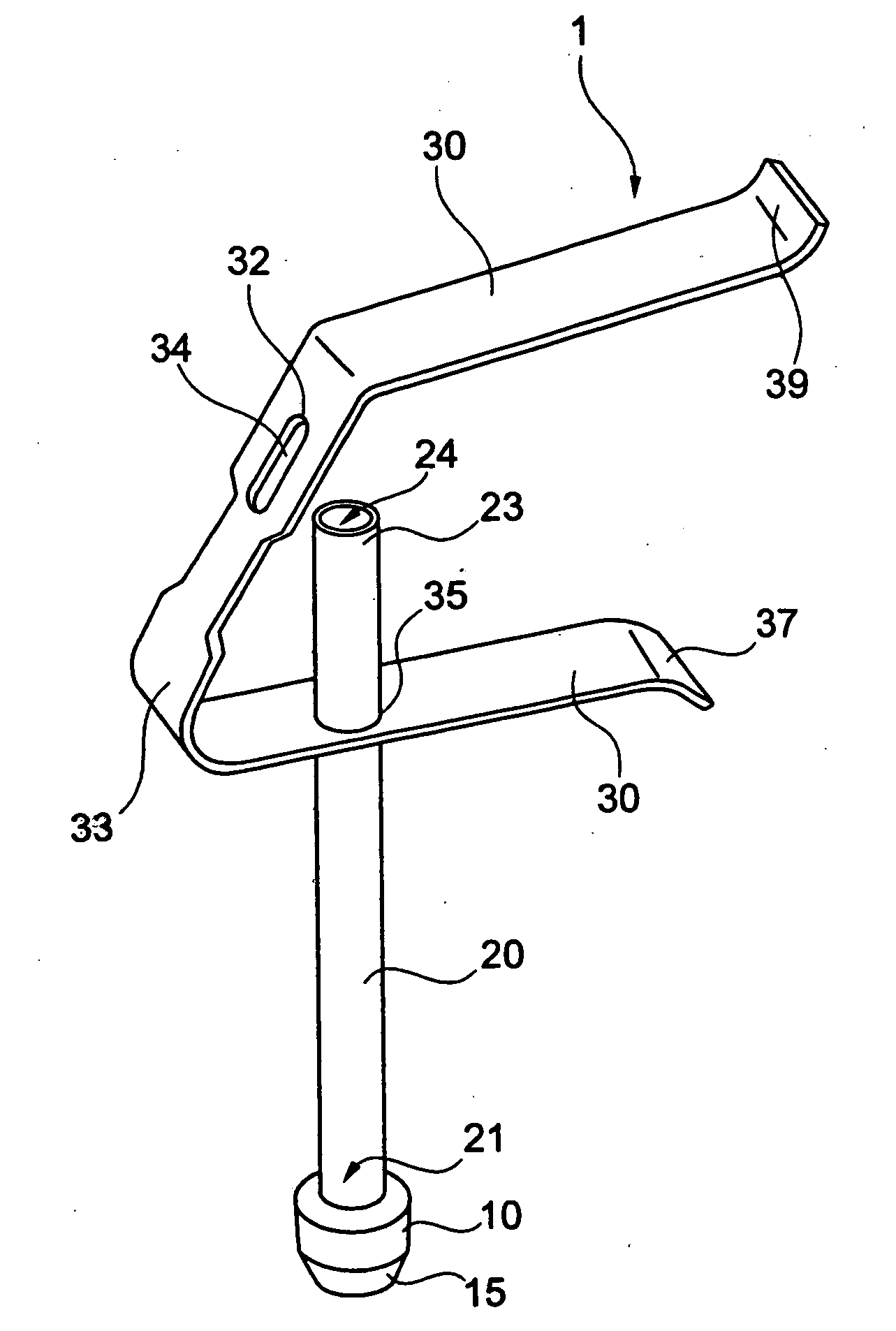

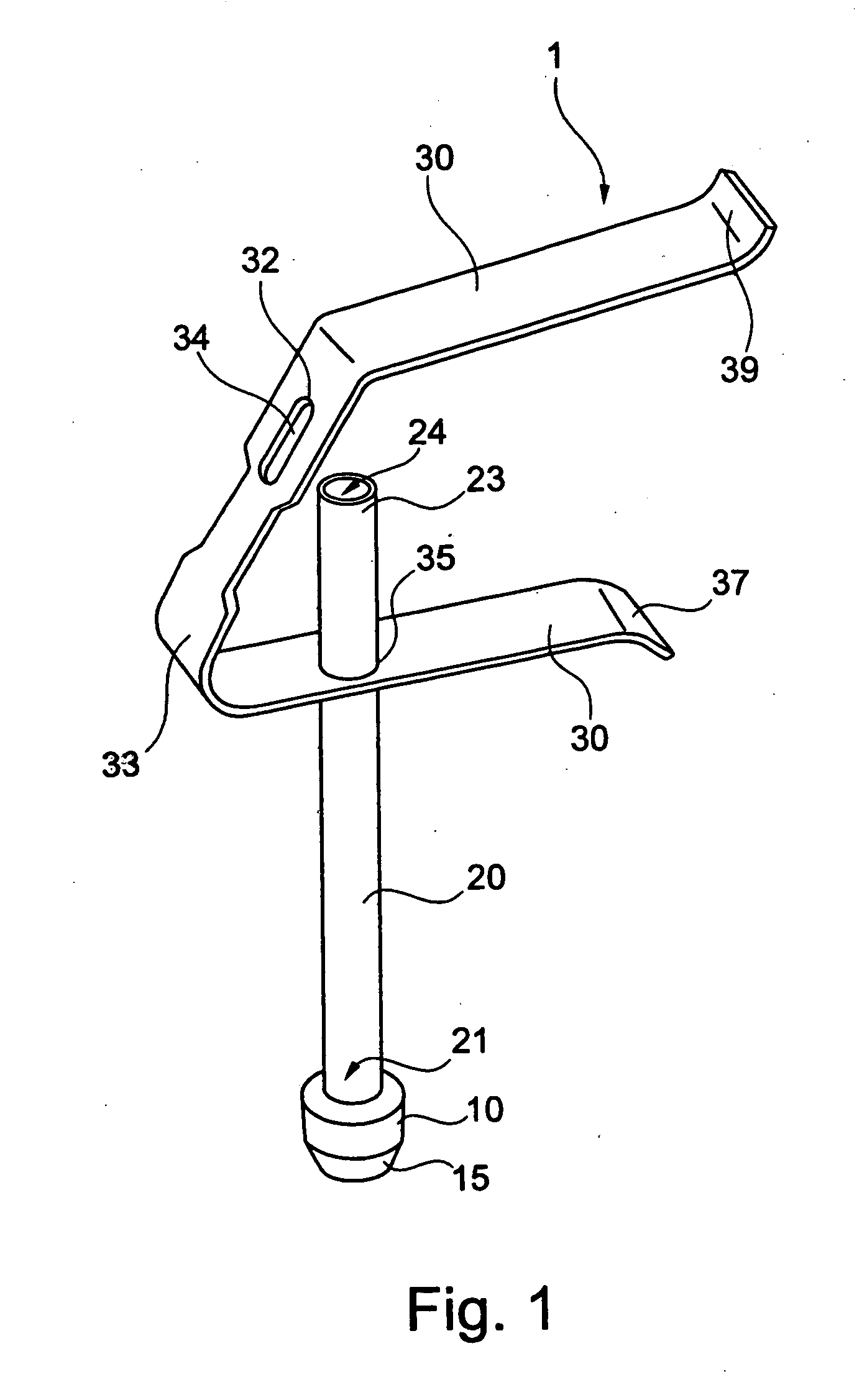

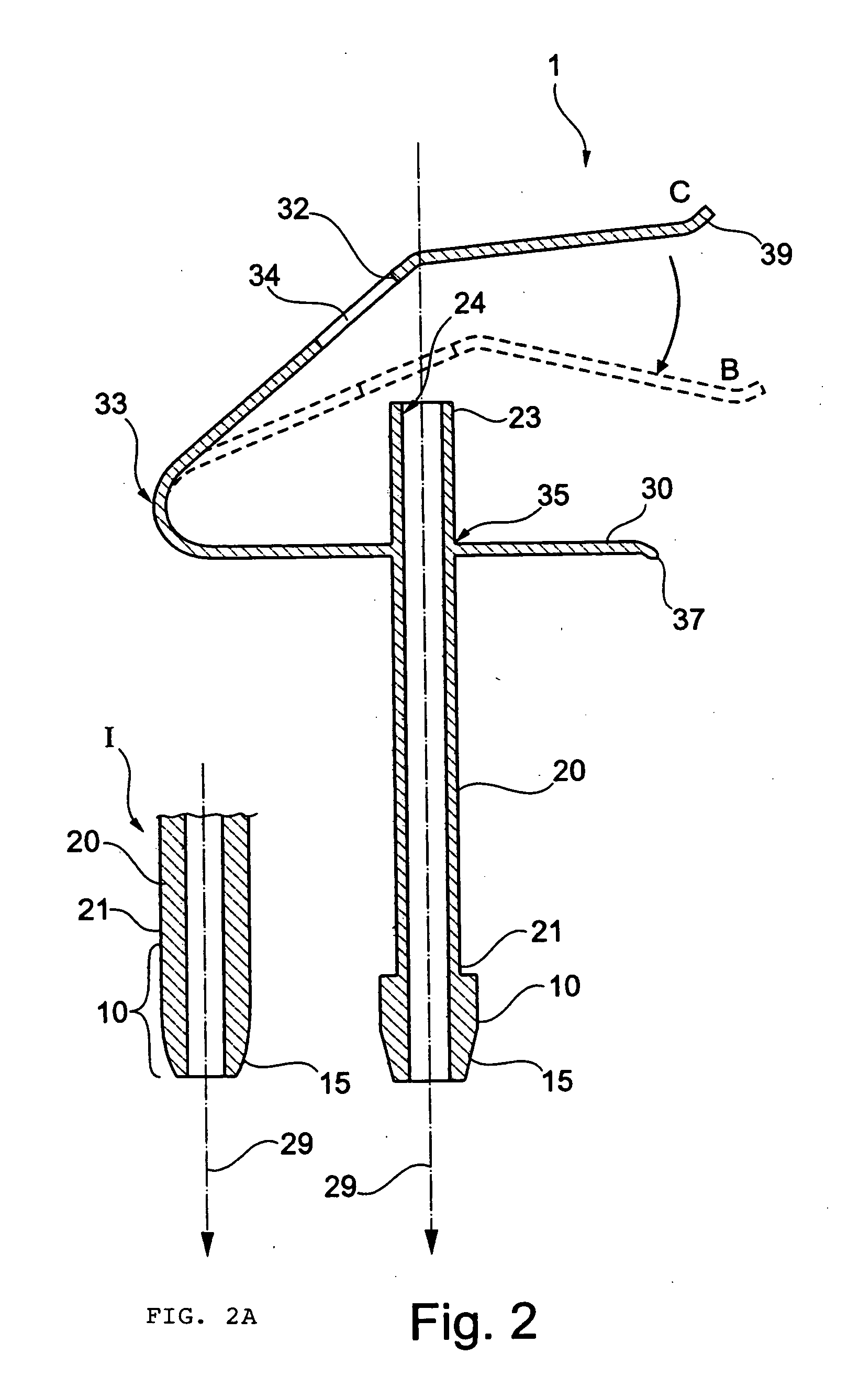

[0039]Referring to FIG. 1 there is shown a perspective view of a preferred Kirschner wire clamp 1 according to the invention. The Kirschner wire clamp 1 shown in FIG. 1 comprises a guide element 20. Furthermore, a base element 10 is provided, which is located in a first end region 21 of the guide element 20. In the preferred embodiment shown, the base element 10 comprises a diameter that exceeds that of the guide element. However, this is not mandatory. Instead, the base element can also be formed to the guide element so as to make a gradual transition, as shown in FIG. 2A in the tip section designated I. In this case that part which essentially is used to guide a Kirschner wire is to be understood to be the guide element, while the base element is understood to be the part which essentially is used as a foundation for the Kirschner wire clamp on the bone plate 50 as shown in FIG. 3. The exertion of force for fixing the bone plate 50 takes place by way of base element 10. In the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com