Method and apparatus for monitoring for leaks in a stage ii fuel vapor recovery system

a technology of vapor recovery system and detection method, which is applied in the direction of liquid transfer device, fluid tightness measurement, instruments, etc., can solve the problem that the escaping fuel vapor can pose a greater threat to the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

case 1

[0053

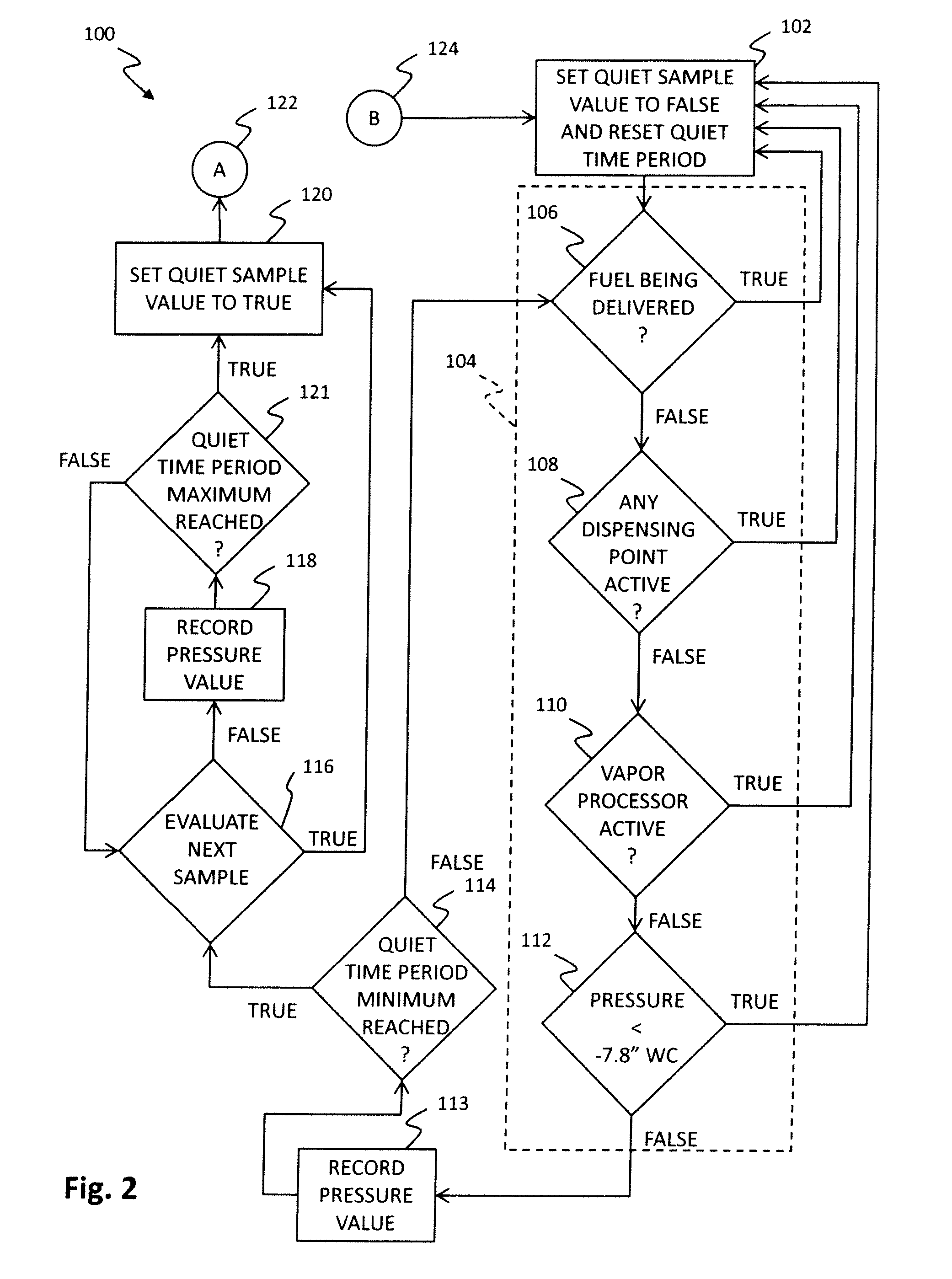

[0054]In case 1, the pressure starts negative and ends less negative. The static pressure resulted in an R2 that is less than 0.90. This indicates the pressure has saturated. Since the pressure remains in the negative region, it indicates that the system is not leaking, thereby resulting in a POSITIVE.

case 2

[0055

[0056]Case 2 is similar to case 1 except the quiet time ended during the upward movement toward zero. Case 2 resulted in an inconclusive test based solely upon the R2 value because the quiet time ended prematurely. One does not know if the slope would continue through the zero pressure region into the positive region or would flat line in the zero region. Therefore the controller will run the slope calculation, described above.

case 3

[0057

[0058]Case 3 occurs when the ending negative pressure is more negative than the starting negative pressure. It is highly unlikely for a leaking tank to result in a more negative ending pressure from what it started at. There is thus no need for the controller to calculate the R2 for this case because any value of R2 would result in a POSITIVE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com