Monolithic structurally complex heat sink designs

a heat sink and monolithic technology, applied in the field of heat sinks, can solve the problems of inability to make such complex structures, need more complex structures to improve the performance of heat sinks, and traditional methods of manufacturing heat sinks are not suited to making such complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

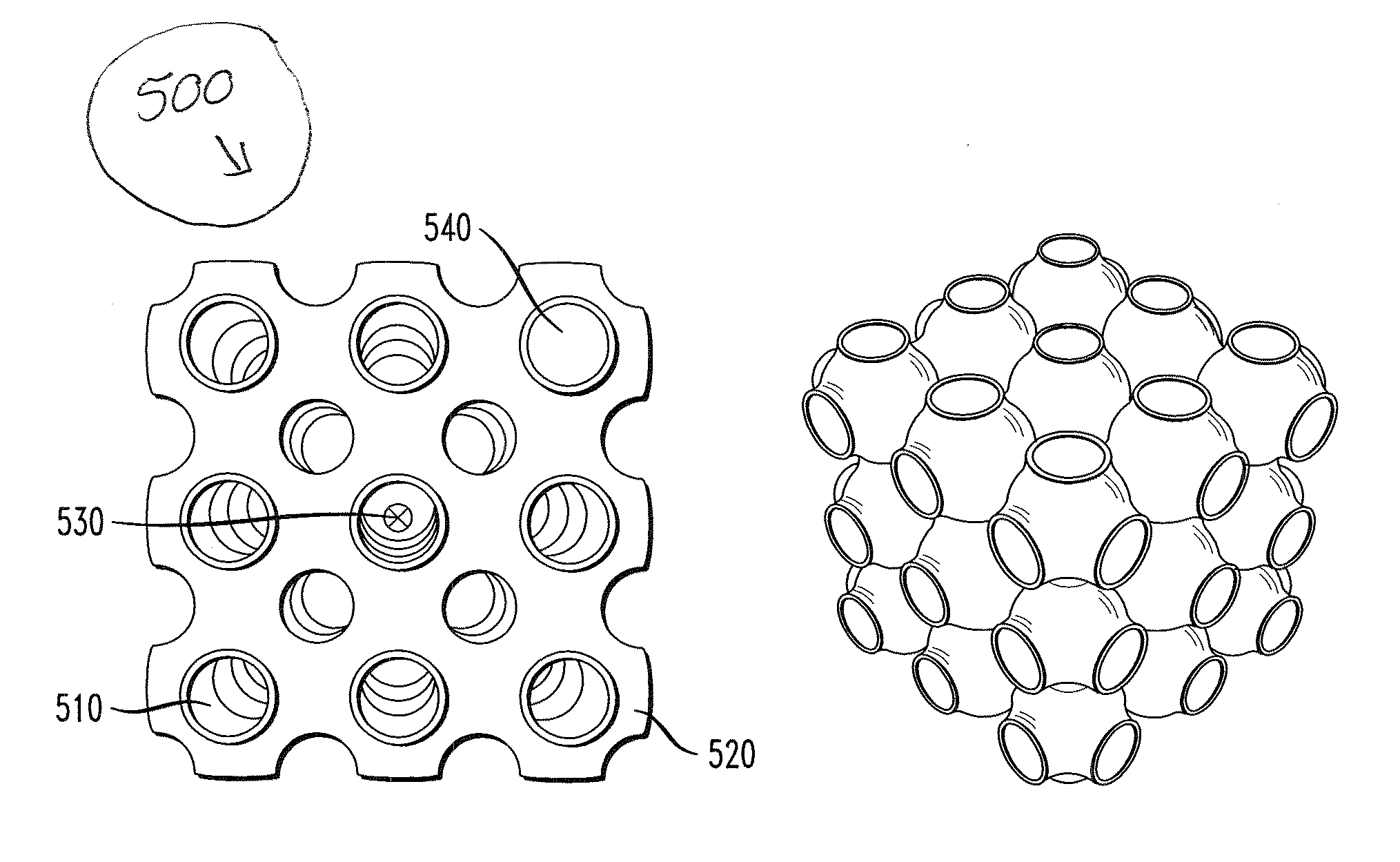

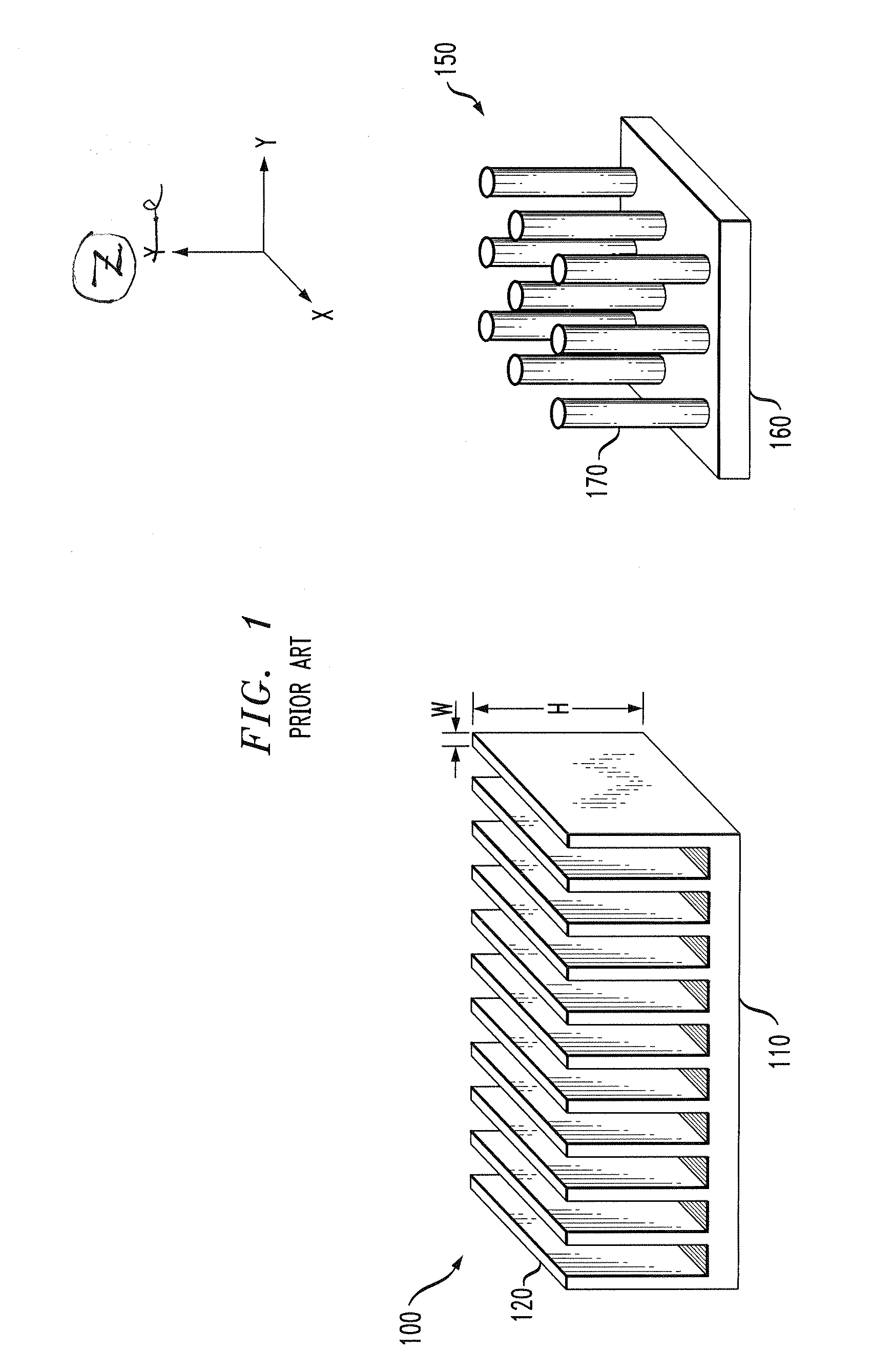

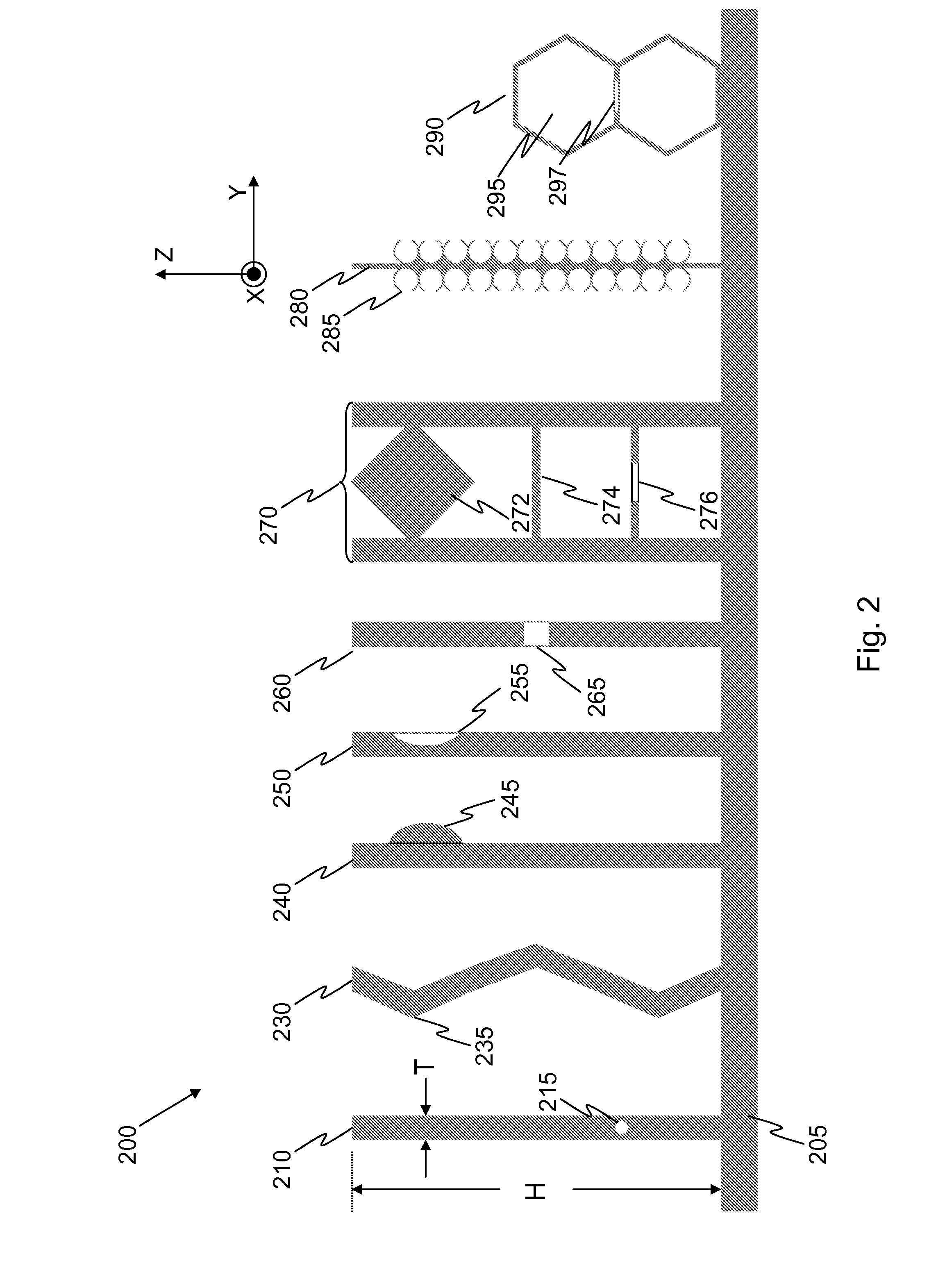

[0016]Embodiments described herein reflect the recognition that three dimensional (3-D) rendering and investment casting may be employed to manufacture monolithic heat sinks with structural complexity unattainable by prior art methods. Such complexity in a monolithic heat sink design provides a means to form heat sinks with novel structural features to improve the performance of such heat sinks over prior art heat sinks. The described embodiments make structural elements available to heat sink designers hitherto unattainable. The availability of these elements provides the designer with the ability to take greater advantage of flow mechanics and heat dissipation physics than with “simple” heat sinks, defined below. Embodiments are described herein that result in a significant improvement of heat transfer characteristics of a structurally complex heat sink relative to simple heat sinks.

[0017]The present discussion introduces the concept of using 3-D printing of a sacrificial pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com