Heat dissipation device

a heat dissipation device and heat dissipation technology, which is applied in the direction of semiconductor devices, lighting and heating apparatus, tubular elements, etc., can solve the problems of not being able to adjust to meet different electronic devices or the same electronic devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

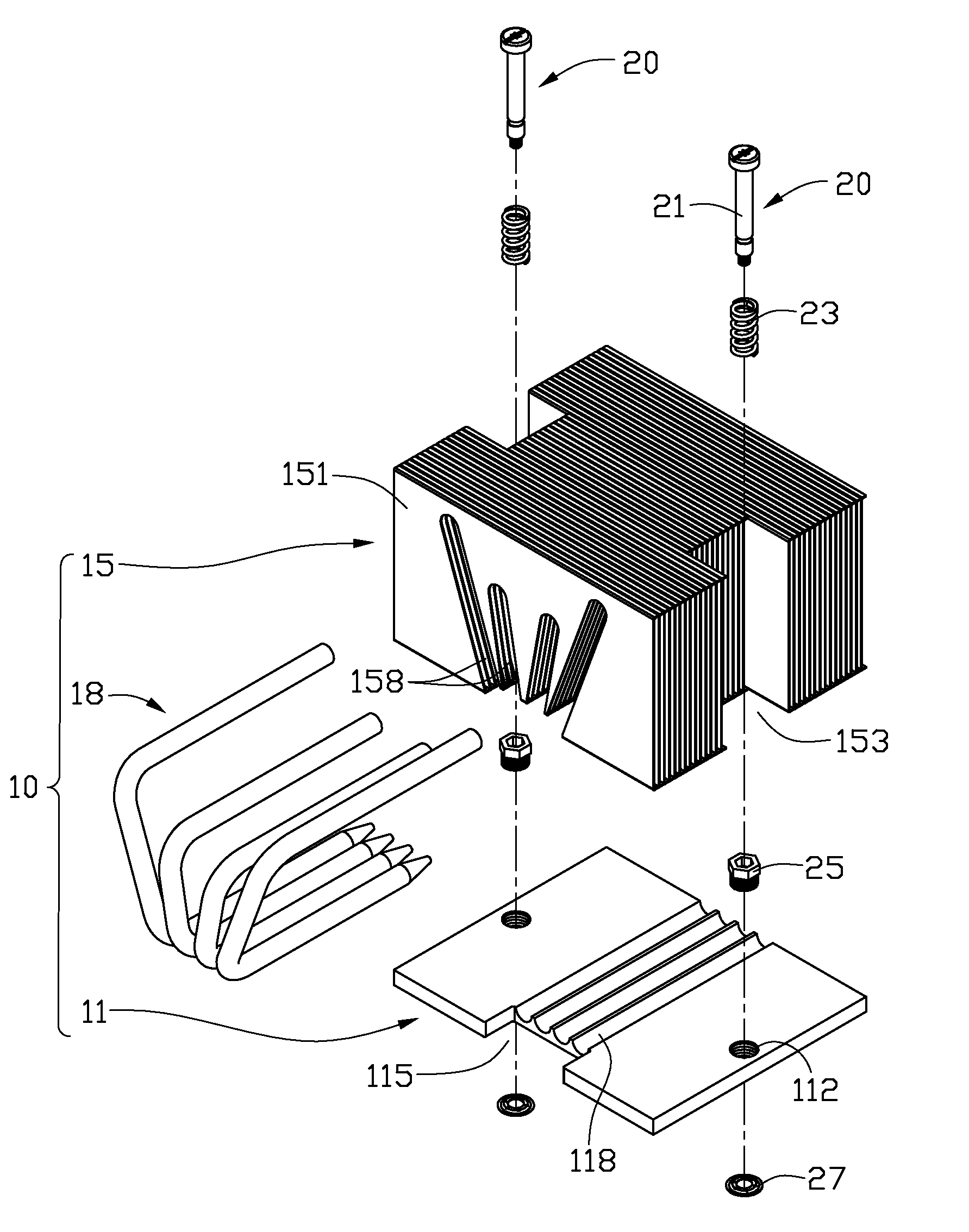

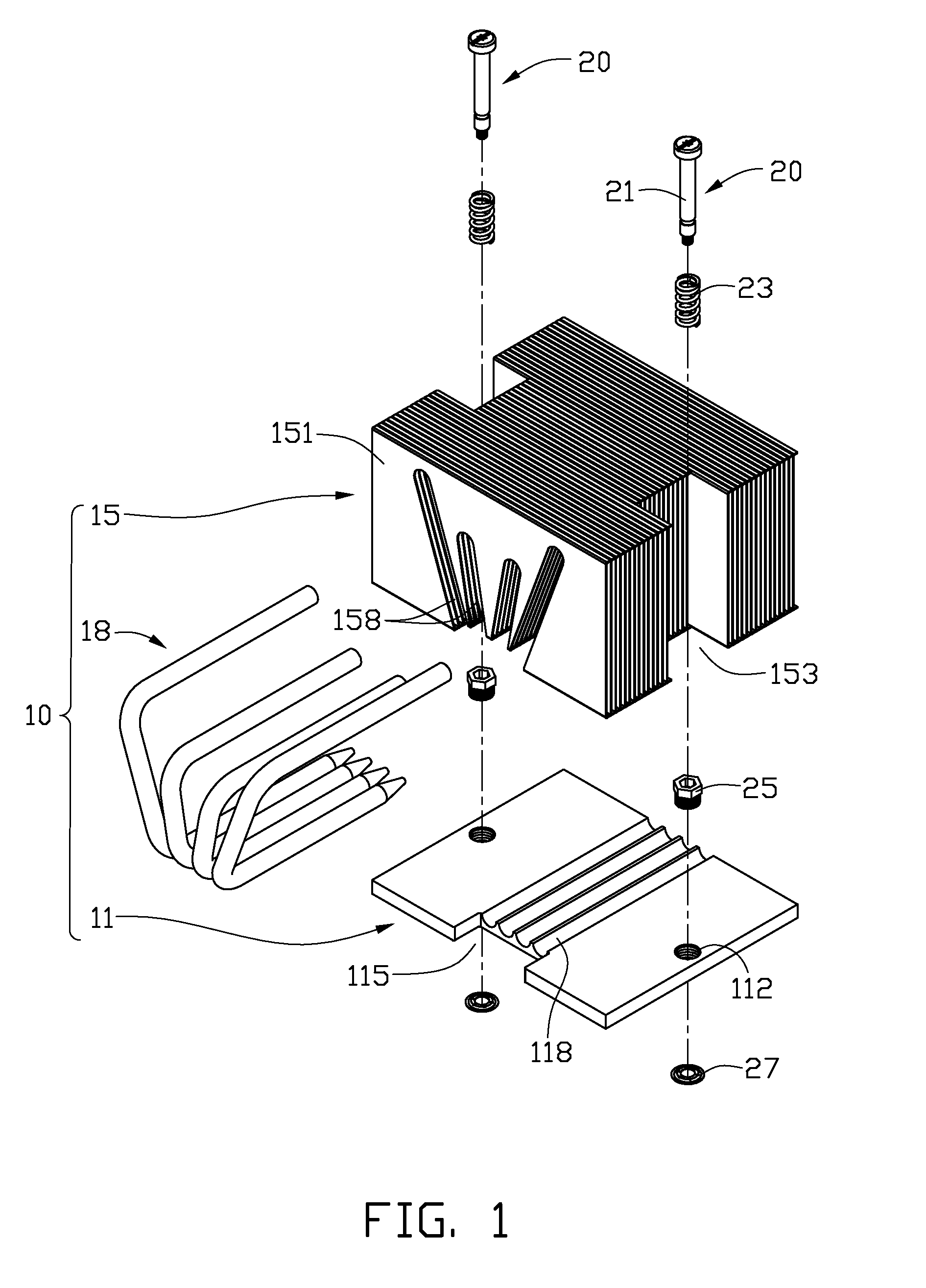

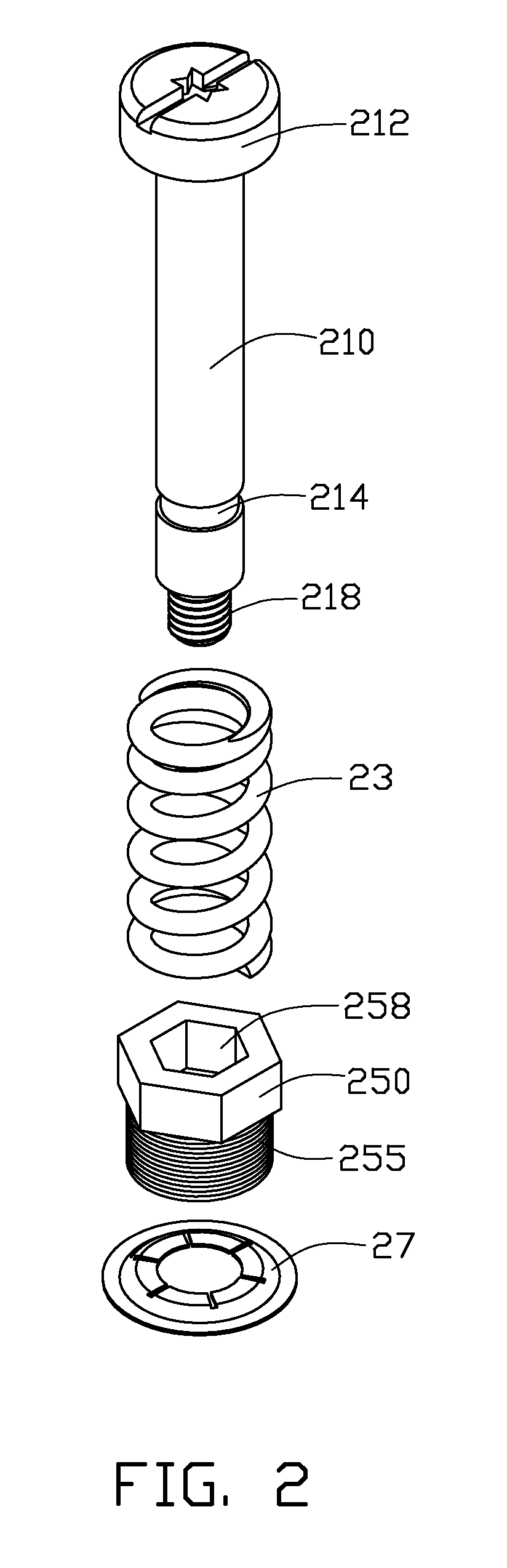

[0015]Referring to FIG. 1, a heat dissipation device of a preferred embodiment is shown. The heat dissipation device comprises a heat sink 10, two fasteners 20 for fastening the heat sink 10 to an electronic device (not shown) mounted on a printed circuit board (not shown) and two sleeves 25 engaging with the heat sink 10 and the fasteners 20 for adjusting fastening force of the fasteners 20 to the heat sink 10.

[0016]The heat sink 10 comprises a base 11, a fin set 15 arranged on the base 11 and four heat pipes 18 connecting the base 11 and the fin set 15. The base 11 is a substantially rectangular plate having good heat conductivity. The base 11 defines two thread holes 112 in middles of two lateral opposite portions thereof. The base 11 defines four parallel grooves 118 for receiving the heat pipes 18. A cutout 115 is defined in a front side of the base 11, adjacent to front ends of the four grooves 118. The fin set 15 comprises a plurality of fins 151 assembled together. Each of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com