Protective Cover For Paint Can

a protective cover and paint can technology, applied in the field of scraping, can solve the problems of excessive paint on the brush, design of the conventional paint can not allow the painter to properly unload excess paint off the brush, and the painting has typically been a very messy job, so as to prevent the brush from drying out, prolong the life of the brush, and neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The embodiments of the protective cover of the present invention are illustrated in combination with a one gallon cylindrical paint can. However, the protective covers of the present invention can be manufactured for use in combination with essentially any size can of paint or wood stain. In addition to one gallon cans, paints and wood stains are also commonly sold in one pint and one quart cans, as well as in five gallon bucket. Equivalent metric-size containers of products are also manufactured and sold.

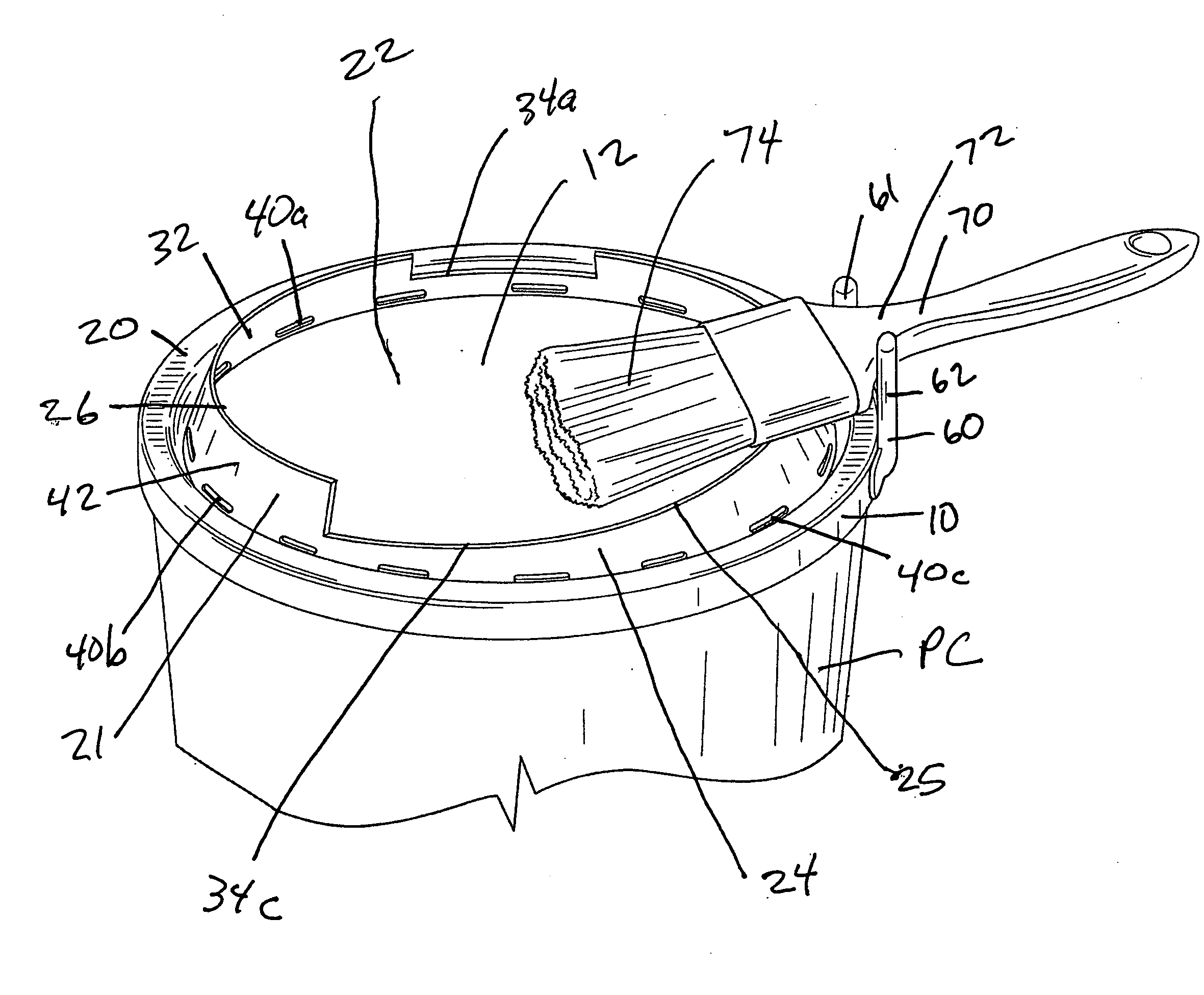

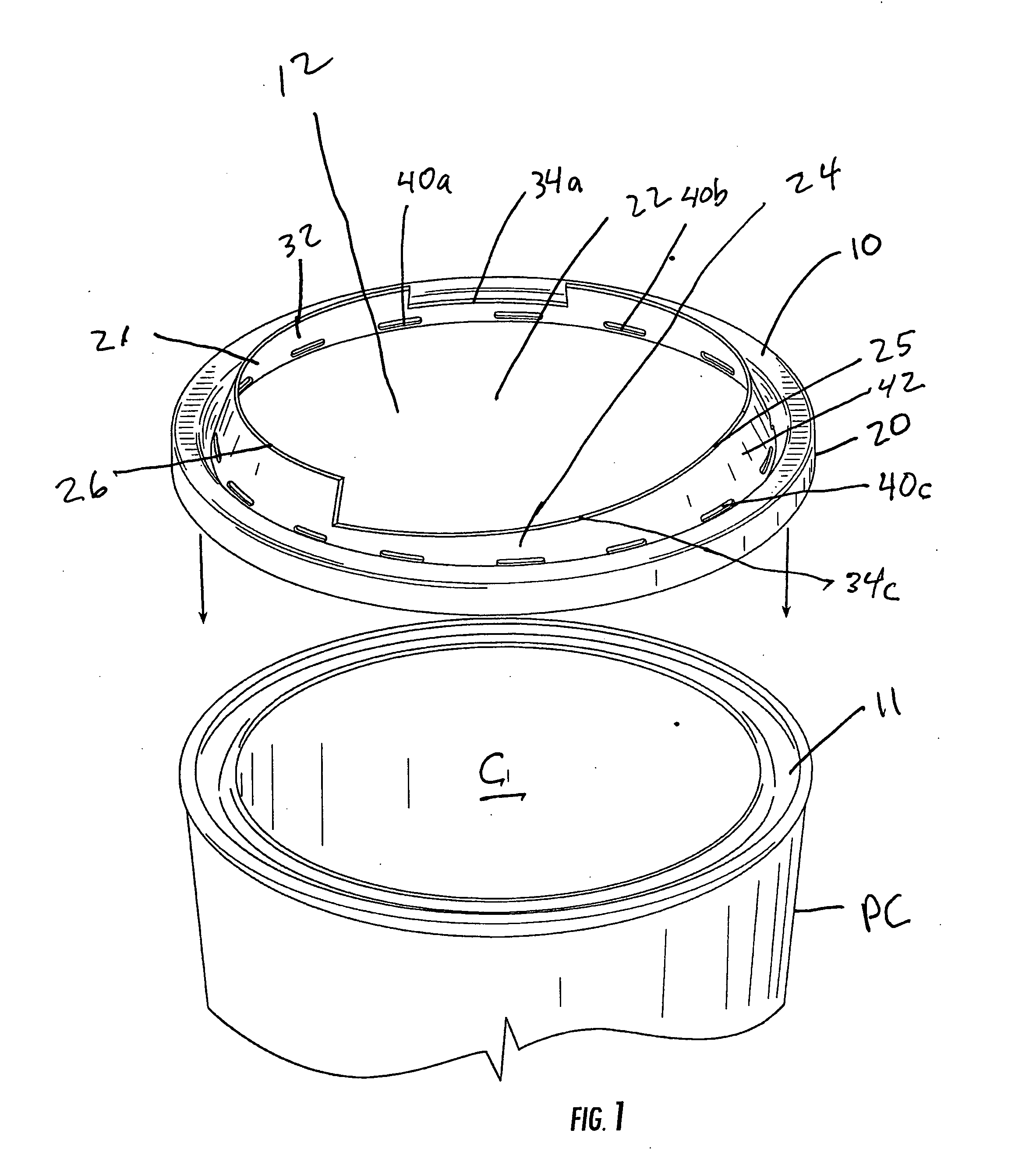

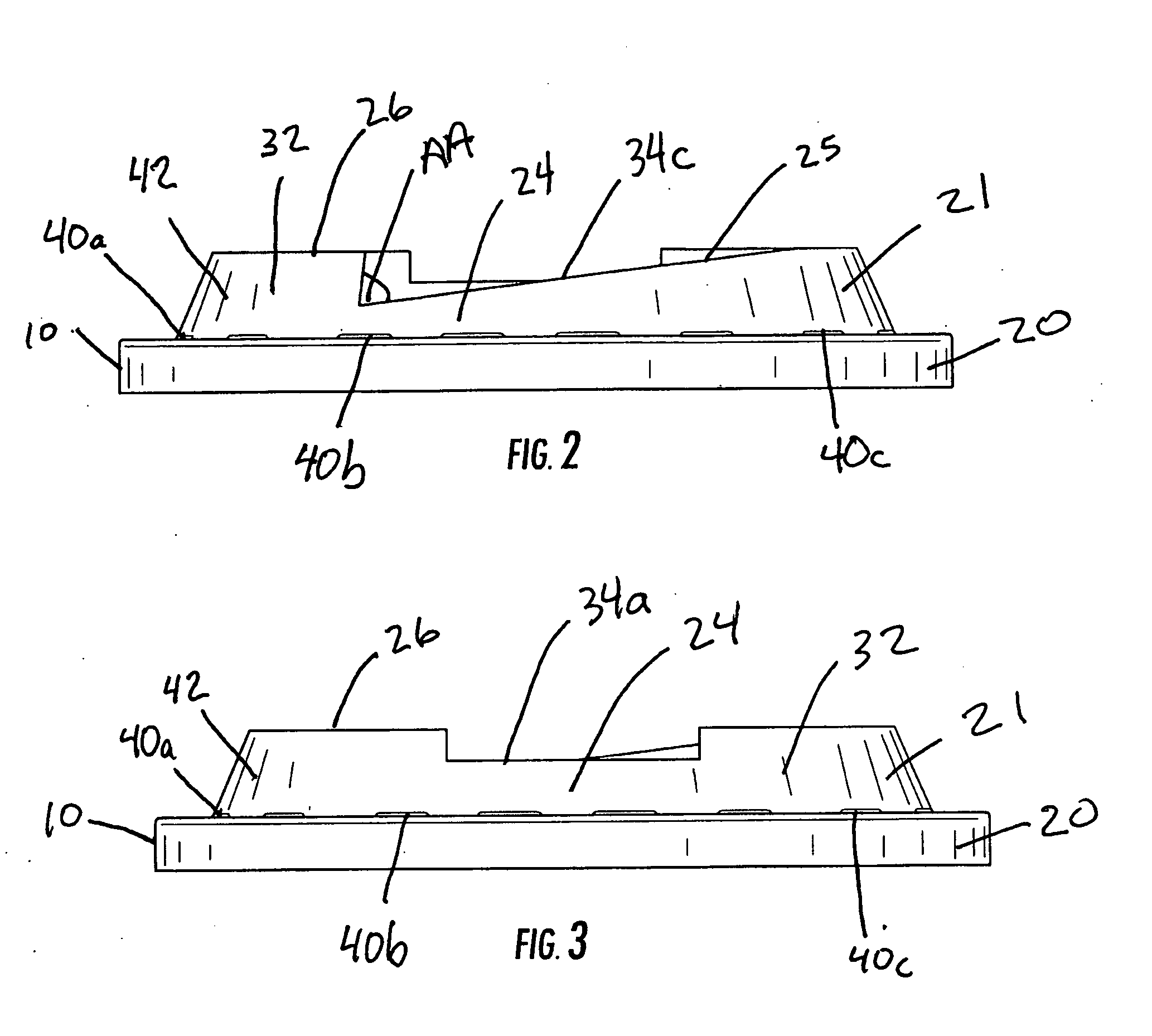

[0022]In the embodiment depicted in FIGS. 1-4, protective cover 10 includes circular cap 20 having an inner lip and an outer lip that are disposed downwardly so that they cooperatively frictionally fasten protective cover 10 to circular channel 11 of paint can PC. The inner and outer lips of circular cap 20 co-operatively seal circular channel 11 of paint can PC so that excess paint cannot collect and dry in circular channel 11. One purpose of the protective cover of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com