Base structure of golf club bag

a golf club bag and base technology, applied in the field of golf club bags, can solve the problems of golf club bags placed slantingly, prone to shake, and the conventional foot frame structure still has some drawbacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

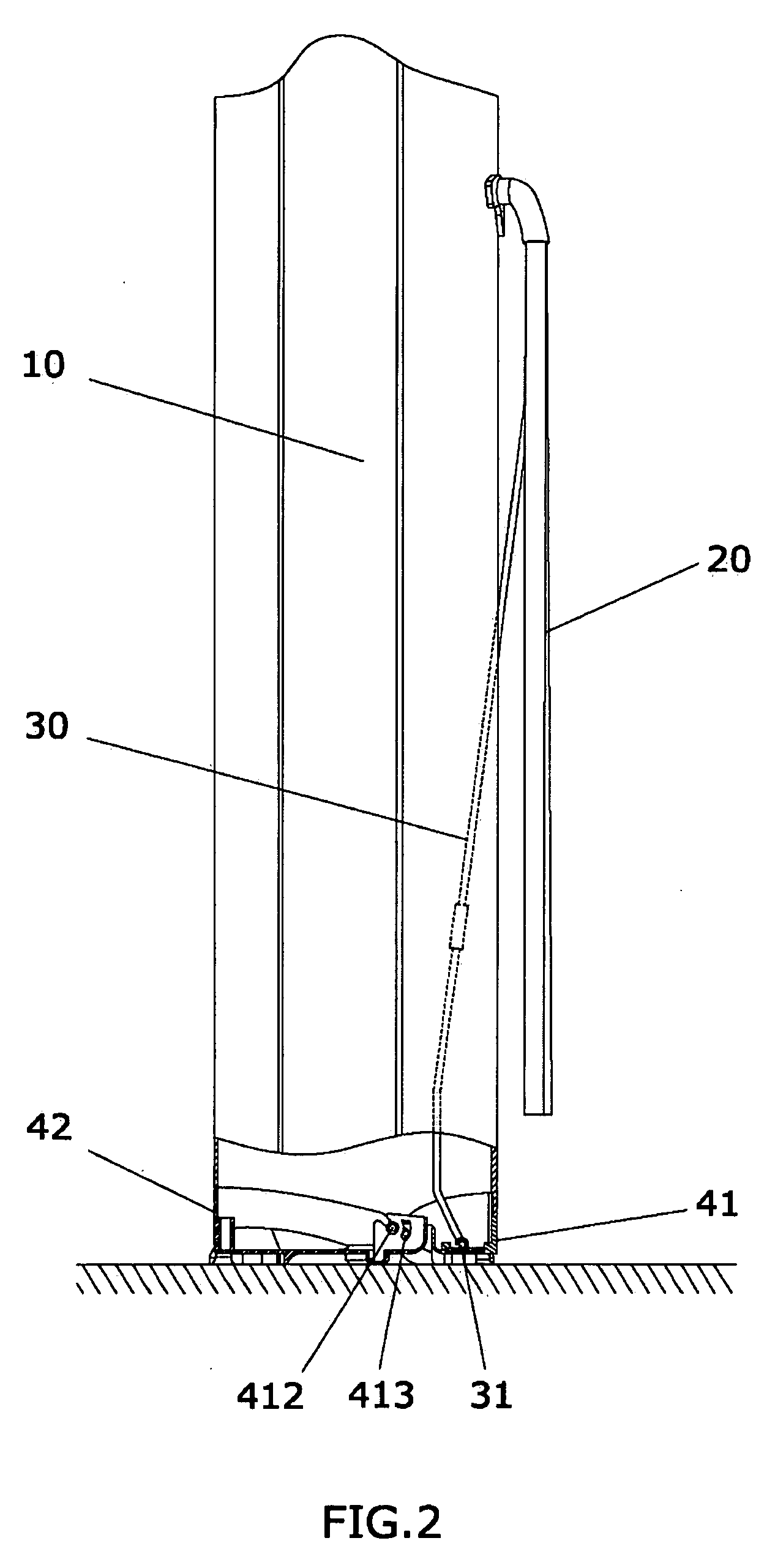

[0022]FIGS. 2 to 5 show the embodied structure according to the preferred embodiment of the invention. Referring to FIGS. 2 to 5, a golf club bag includes a bag body 10, a main support rod 20, a linking rod 30 and a base 40. The bag body 10 is fixed to the base 40. The top end of the main support rod 20 is pivotally connected to the vicinity of a frame opening of the bag body 10. The top end of the linking rod 30 is pivotally connected to the middle-upper portion of the main support rod 20. The bottom end of the linking rod 30 is pivotally connected to the base 40.

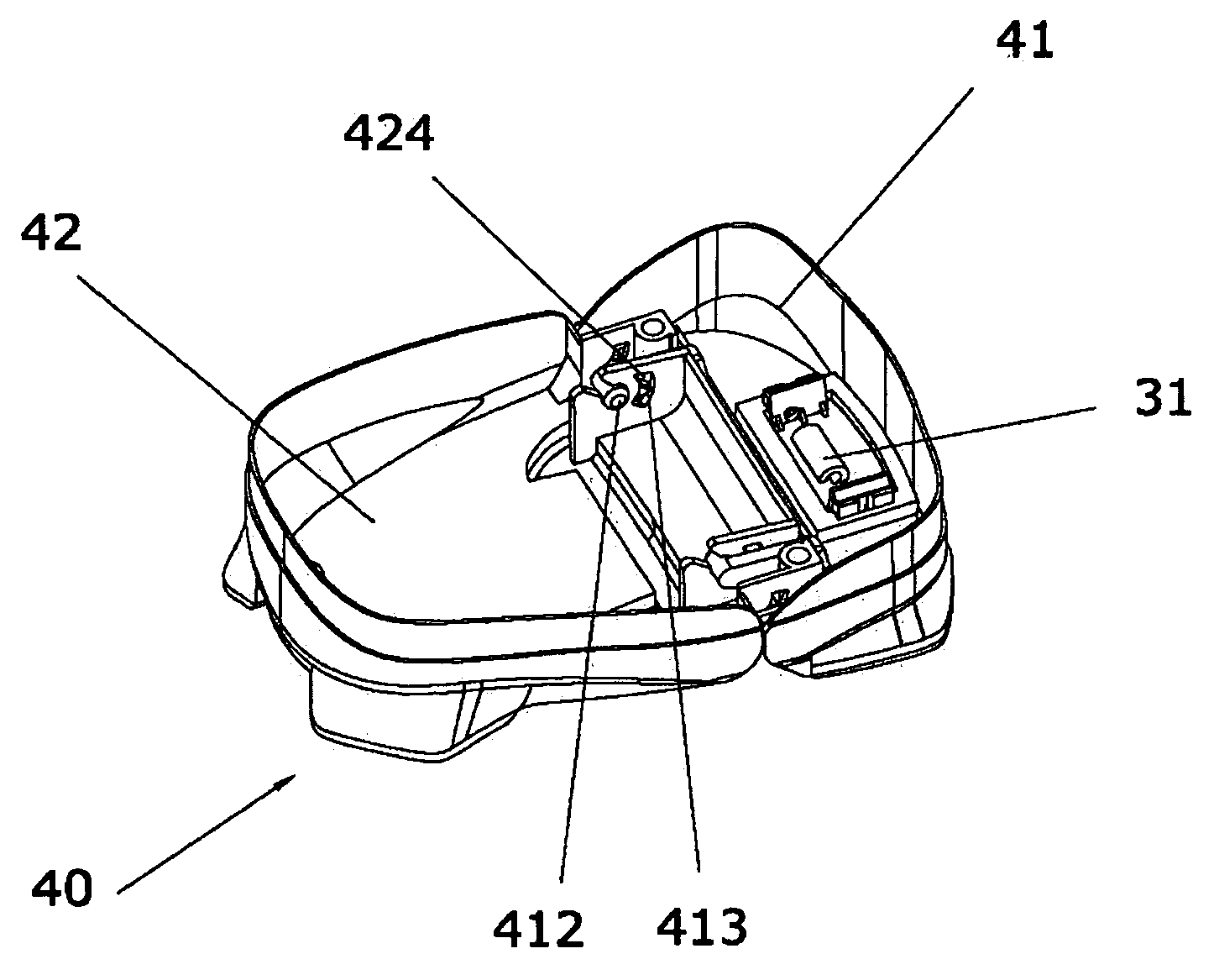

[0023]The base 40 is composed of a front base 41 and a rear base 42, which have the substantially the same width and are pivotally connected to each other. A periphery of a bottom end of the bag body 10 is simultaneously sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com