Muzzle brake and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

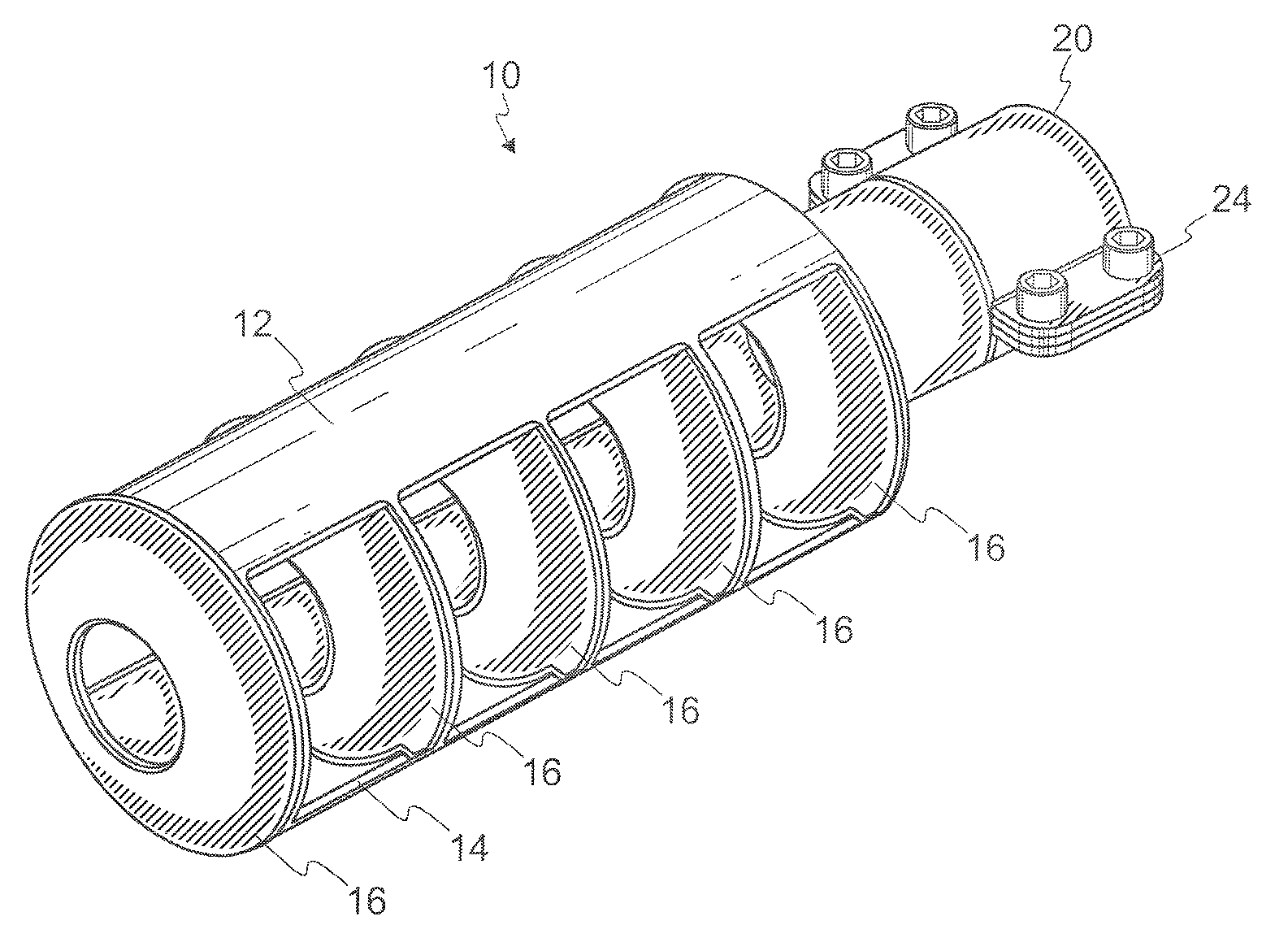

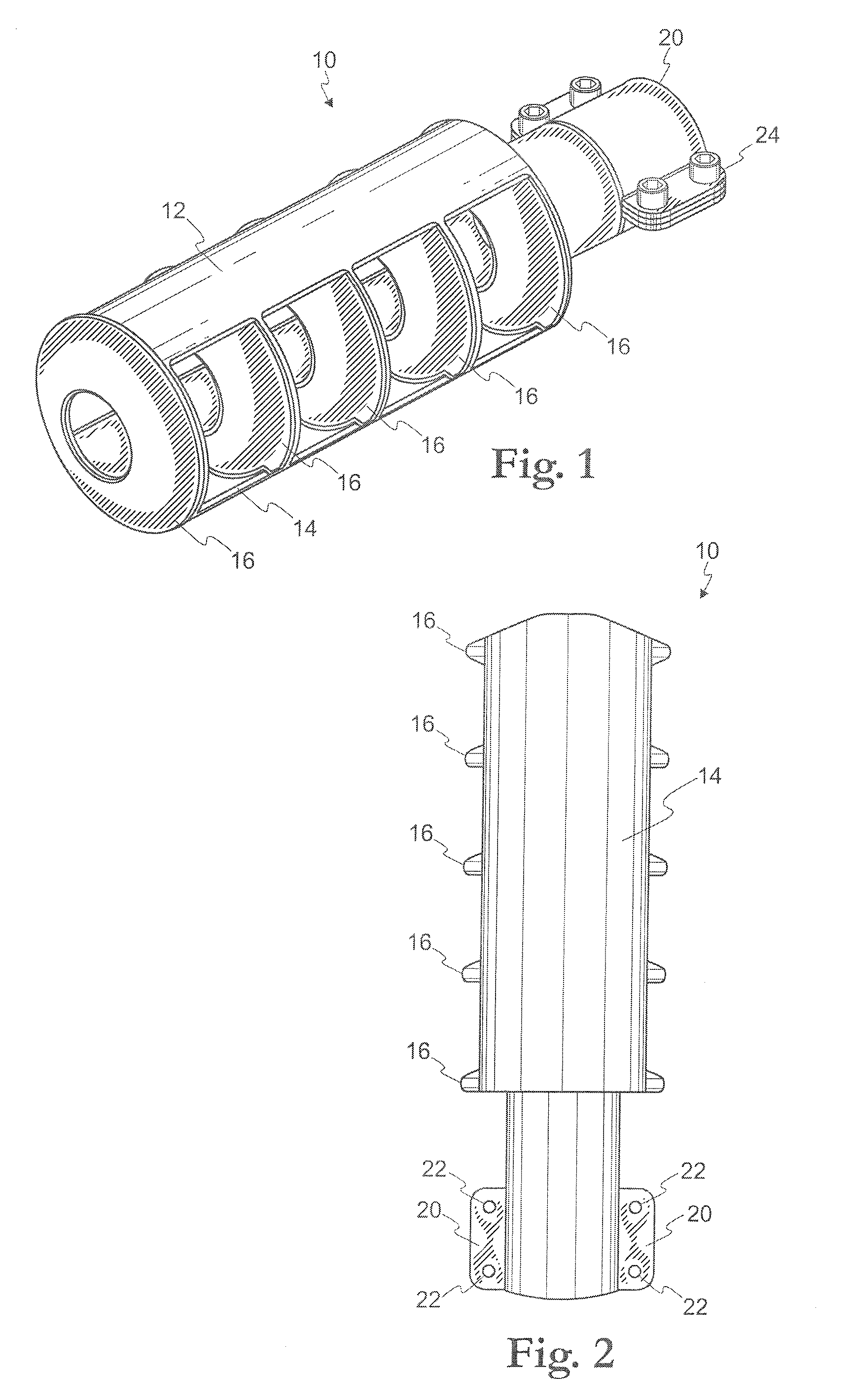

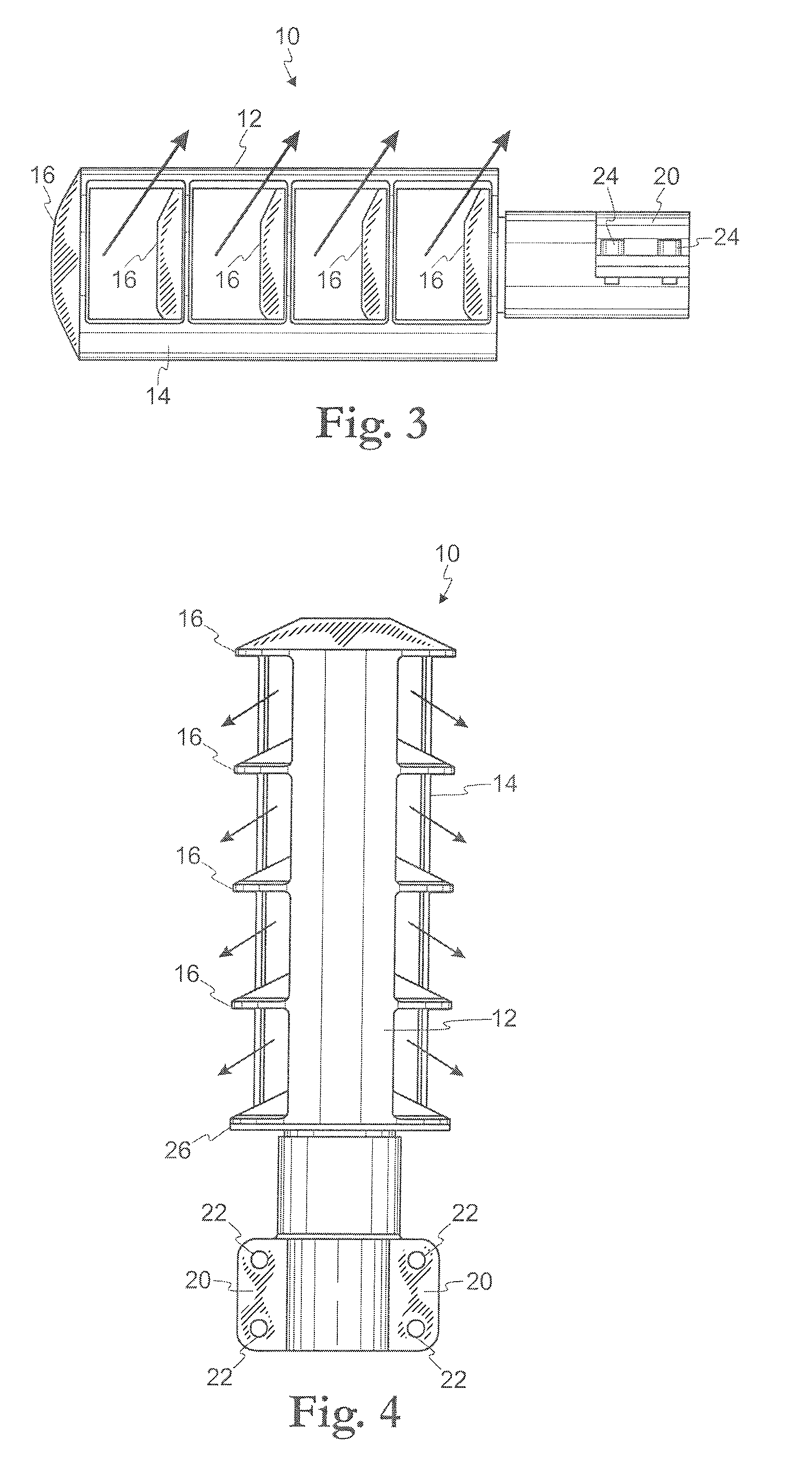

[0015]Referring initially to FIGS. 1-4, an embodiment of a muzzle gas reduction device 10 is shown. The muzzle gas reduction device 10 is adapted, as described below, to be coupled to an end of a firearm barrel. Preferably, the firearm is a PAN disrupter, though the muzzle gas reduction device 10 of the present invention may be utilized with other types of firearms not associated with disruptors, including canons. The muzzle gas reduction device 10 is adapted to permit a projectile to be fired from the firearm, to pass through the device 10, and to divert sideward and upward muzzle gasses escaping from the end of the firearm barrel.

[0016]The device 10 has, as illustrated in the figures, a substantially barrel shape. It comprises an upper, elongated, curved section 12 and a lower, elongated, curved section 14. As best seen in FIGS. 1 and 4, a width of the upper section 12 is less than a width of the lower section 14.

[0017]Interposed between the upper section 12 and lower section 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com