Mechanical delay timer

a delay timer and mechanical technology, applied in the field of mechanical delay timers, can solve the problems of not being able to control the operation of either a toggle switch or a rocker switch, and cannot be used for control of a conventional wall switch,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

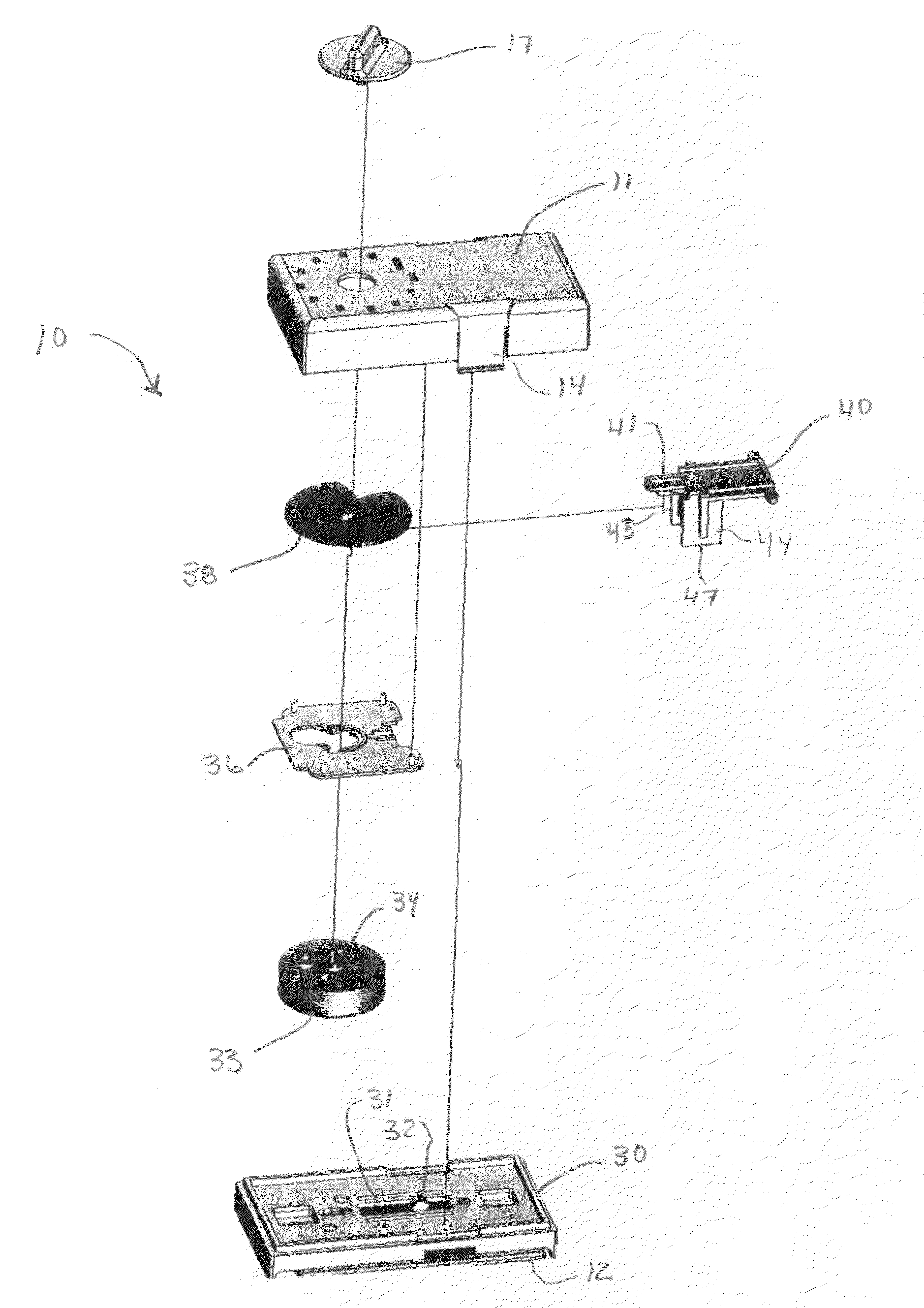

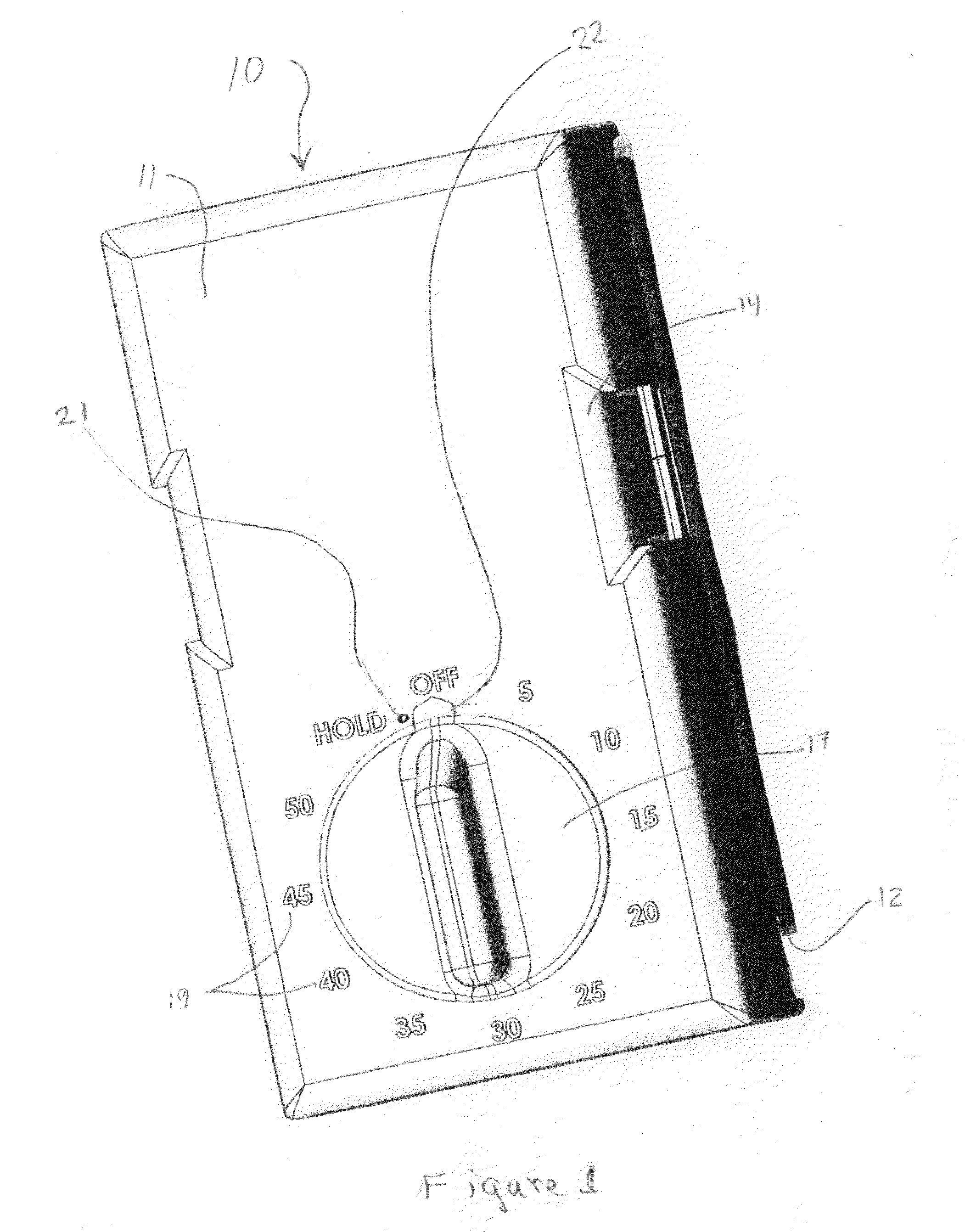

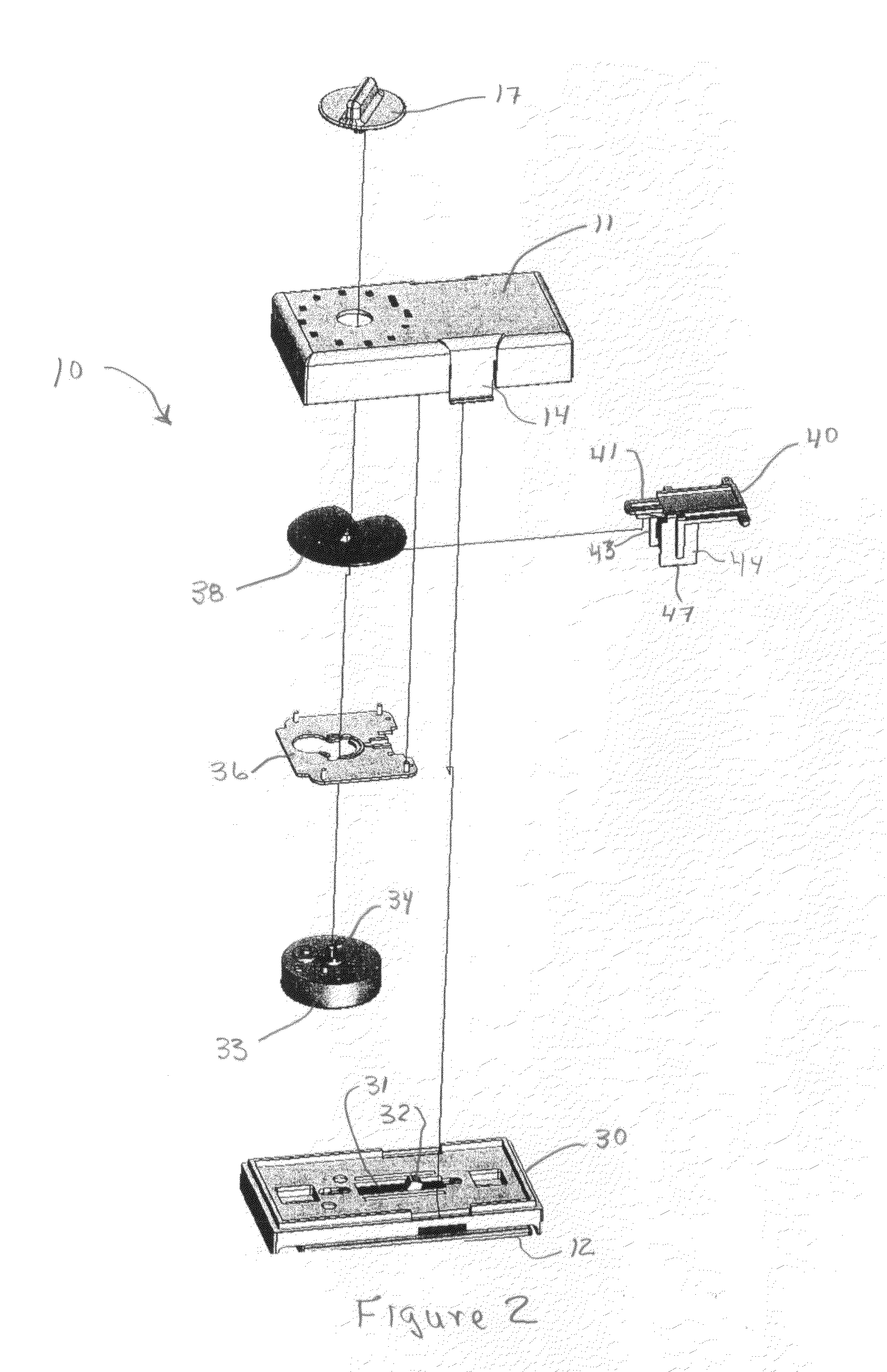

[0017]FIG. 1 shows the delay timer 10 as it would appear mounted over the cover plate of a conventional toggle or rocker wall switch. Timer 10 includes a timer housing 11 that fits over the cover plate 12 of a conventional toggle switch having a protruding lever or handle, or over the cover plate of a rocker switch in which one side of the switch is raised and the other side is depressed. The housing locks to a timer base (not shown in this view) by means of tab locks 14 and 15. A rotatable control knob 17 for setting the time delay for switch operation is located adjacent the bottom of the timer housing and is encircled by a time scale19 that may be calibrated in minutes. The time delay for switch operation is set by clockwise rotation of the control knob to the chosen setting. A small counter-clockwise rotation, from the “off” position to the “hold” position, does not engage the timer, but turns the switch on until the control knob is again turned. A removable stop such as a threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com