Heat Exchanger with End Plate Providing Mounting Flange

a technology of heat exchanger and end plate, which is applied in the direction of indirect heat exchanger, laminated elements, lighting and heating apparatus, etc., can solve the problems of high material usage, difficult manufacturing and relatively expensive of belts of this type, and increase the amount of material required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In the detailed description which follows, various exemplary embodiments are described, particularly with reference to the appended figures. However, the particularly disclosed embodiments are merely illustrative of heat exchangers constructed according to the present disclosure.

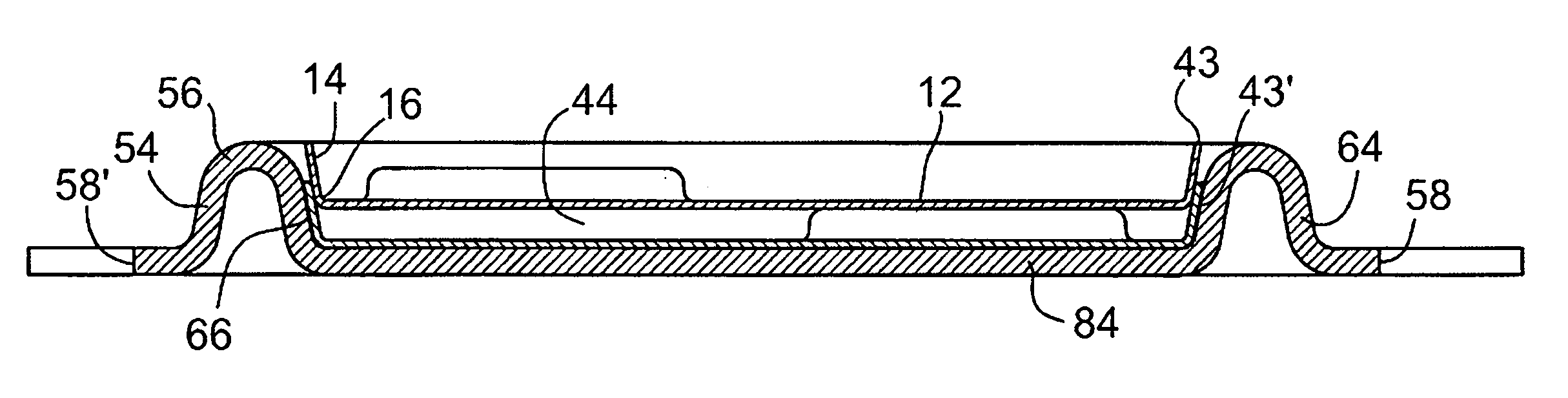

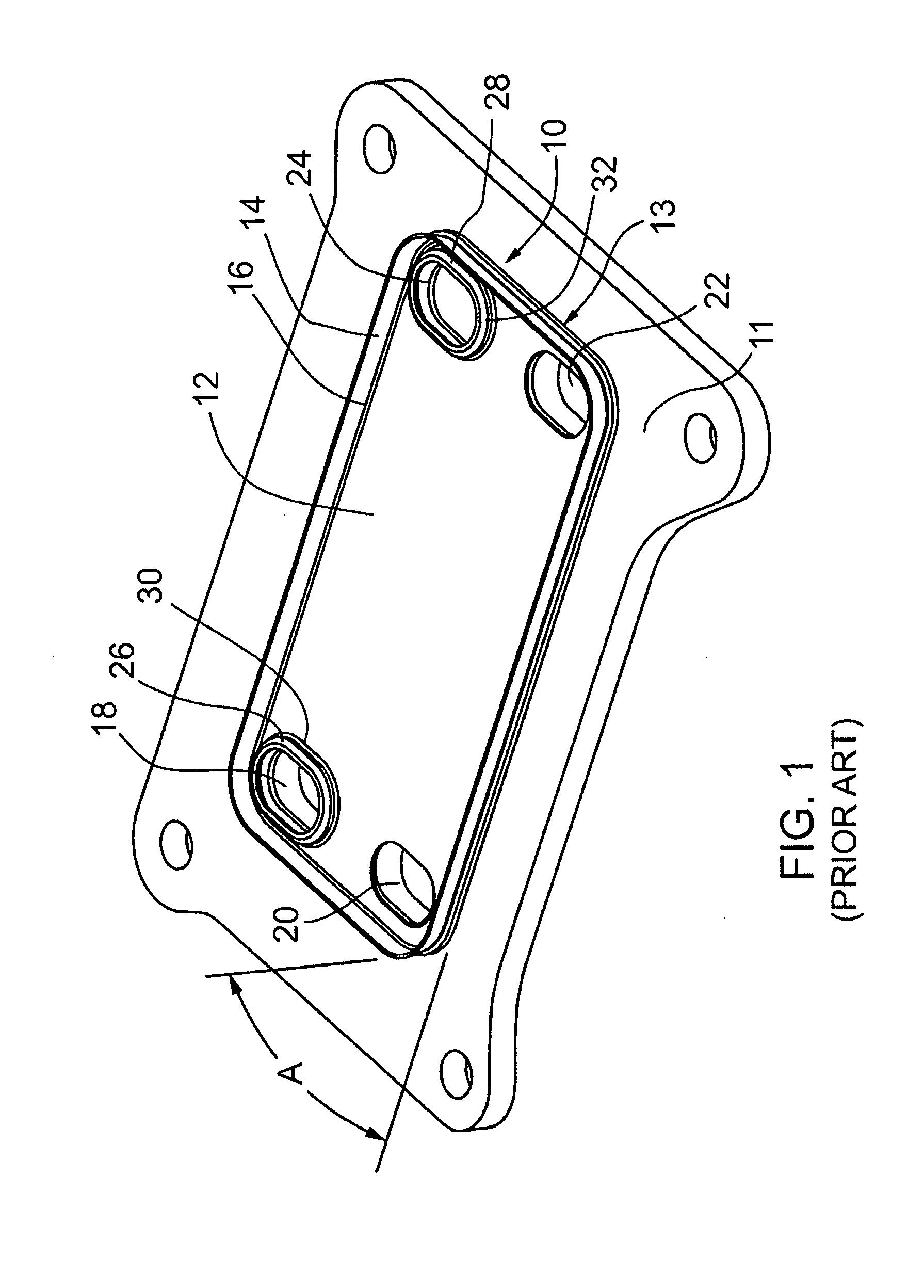

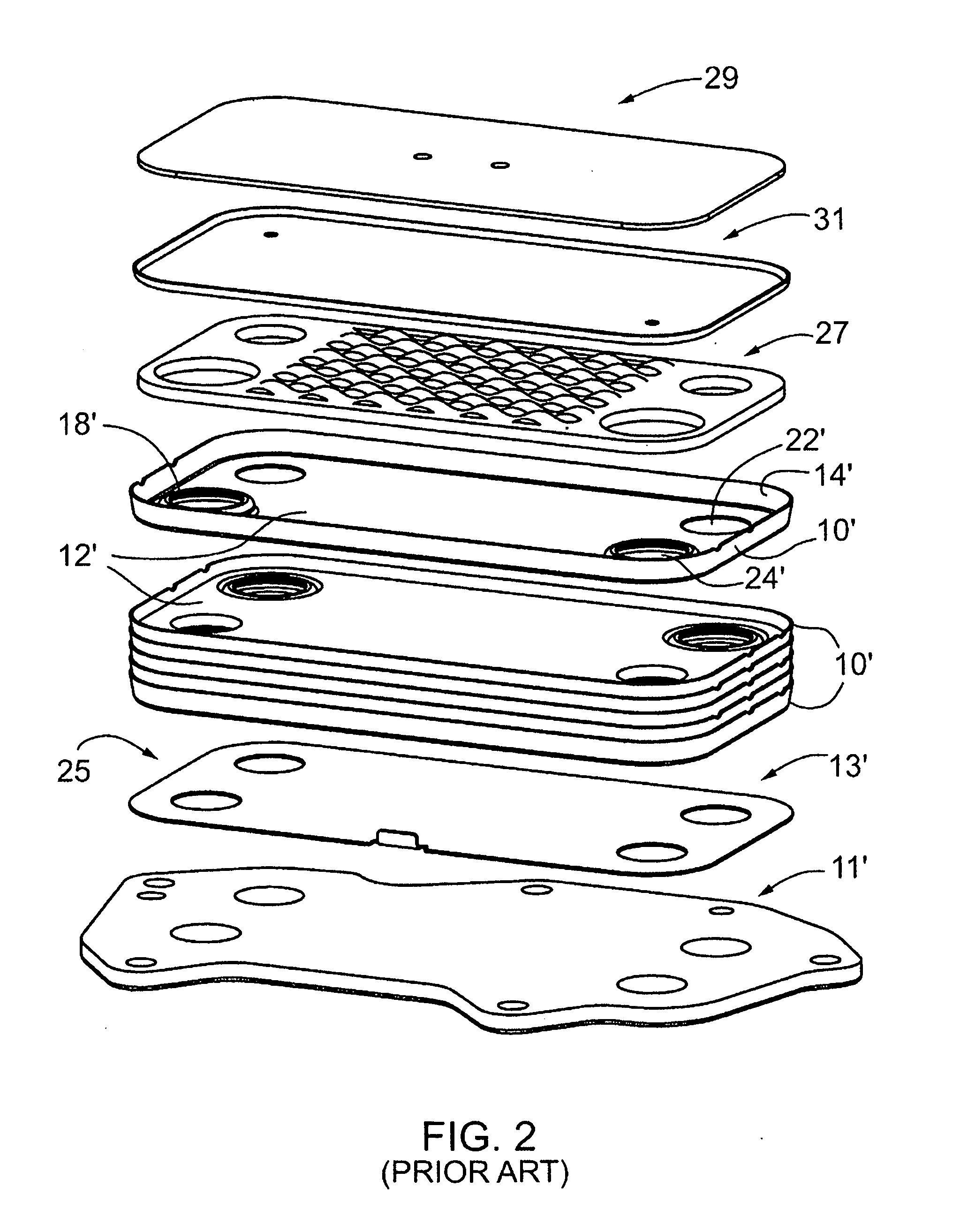

[0022]Referring now to FIG. 1, a conventional heat exchanger plate 10, according to the prior art, comprises a rectangular plate bottom 12 surrounded on all sides by an upwardly and outwardly sloping edge wall 14. The plate 10 is fixedly mounted on a substantially rectangular base plate 11. The bottom 12 constitutes a central main section of the plate 10 having a peripheral edge 16. The edge wall 14 extends outwardly from and around this peripheral edge at an acute angle indicated at A to a plane defined by the main plate section and the base plate 11. A heat exchanger plate of this type is commonly known as a “dished” plate. The illustrated bottom 12 is provided with four holes 18, 20, 22, and 24 near...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com