Solid-state image pickup device

a solid-state image and pickup device technology, applied in the direction of color television details, television systems, radio control devices, etc., can solve the problems of deteriorating image quality, difficult for incident light to reach the photoelectric conversion region, and difficult for the amplifying solid-state image pickup device to obtain excellent sensitivity characteristics, etc., to achieve suppressed sensitivity shading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

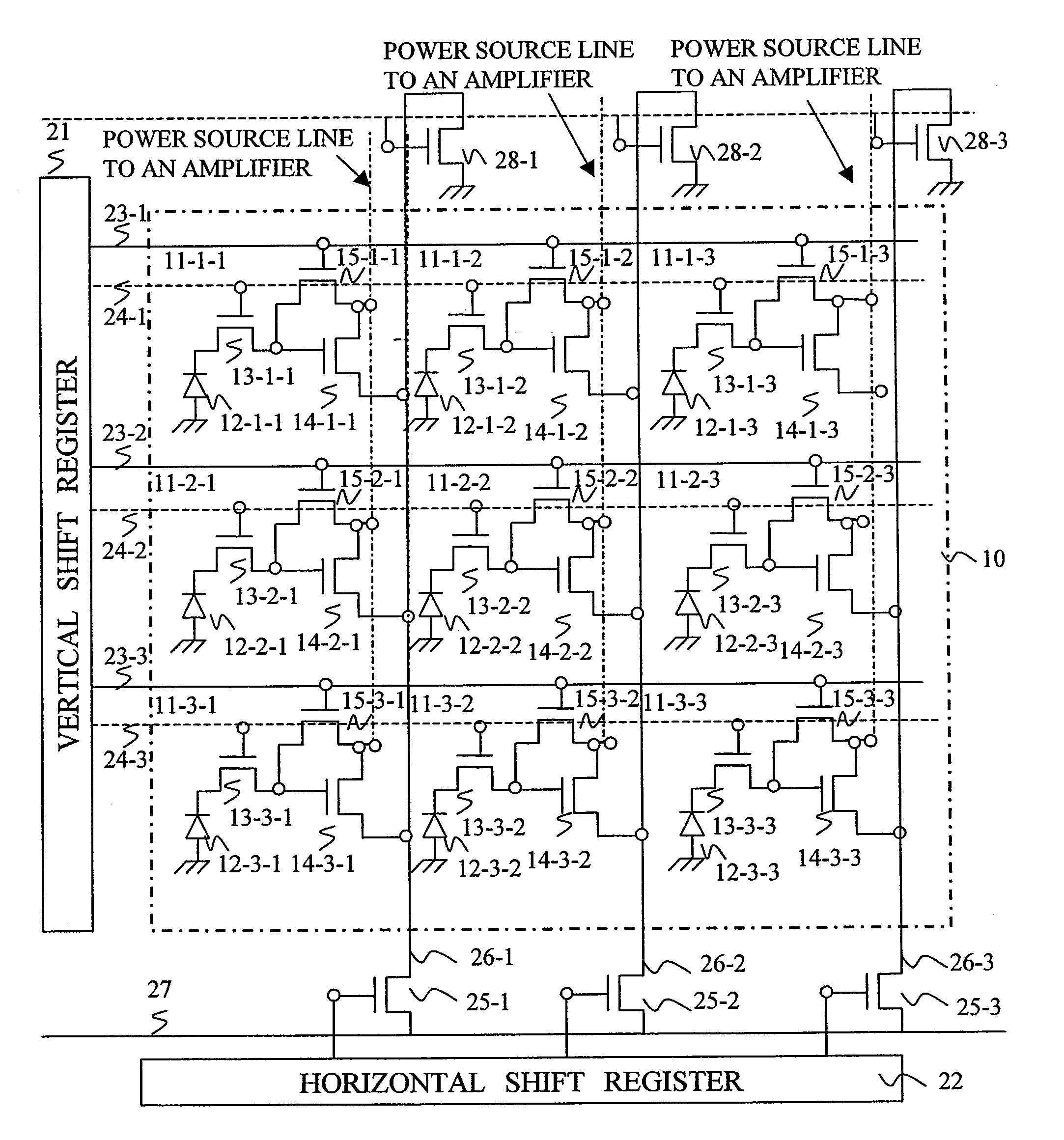

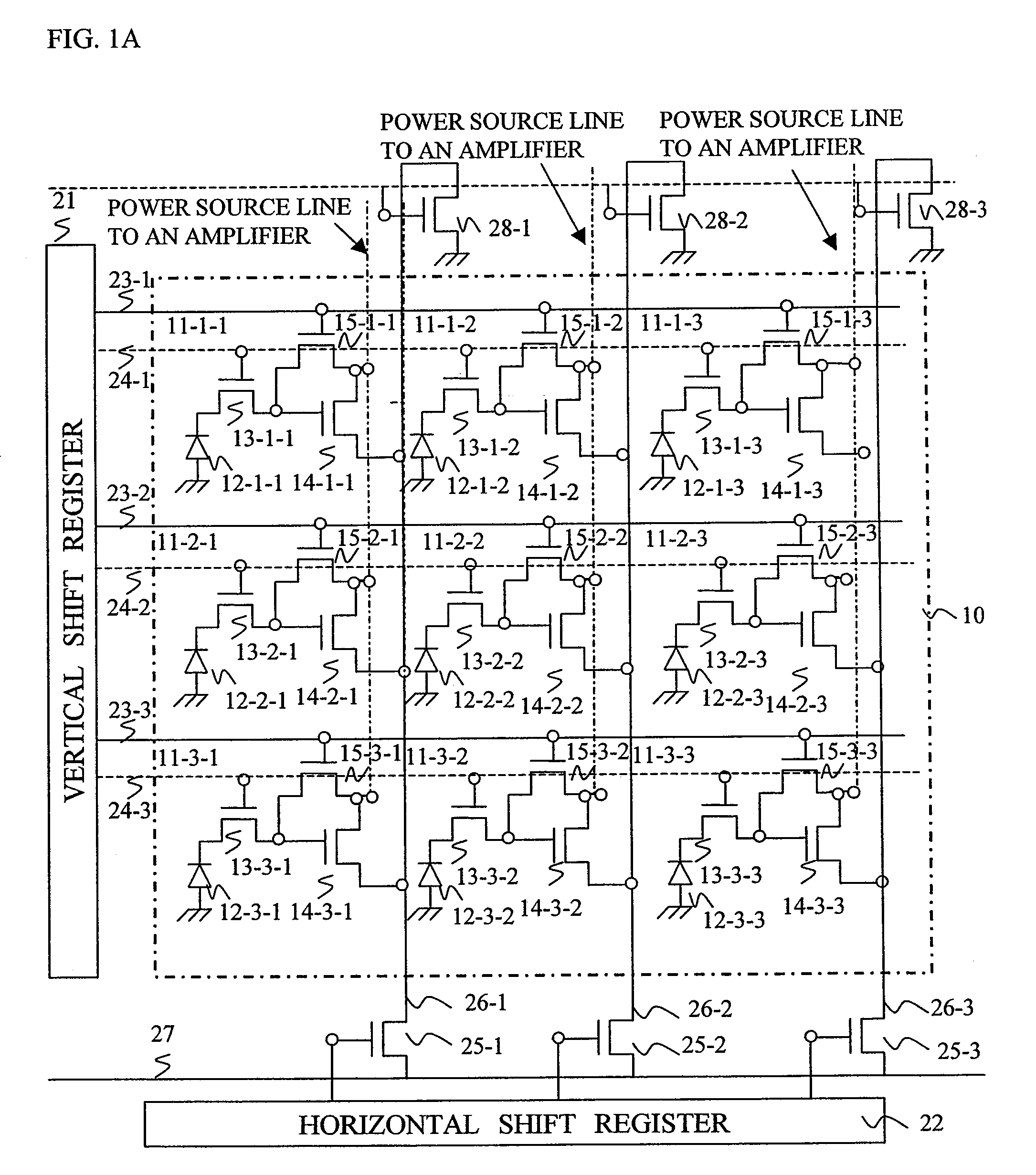

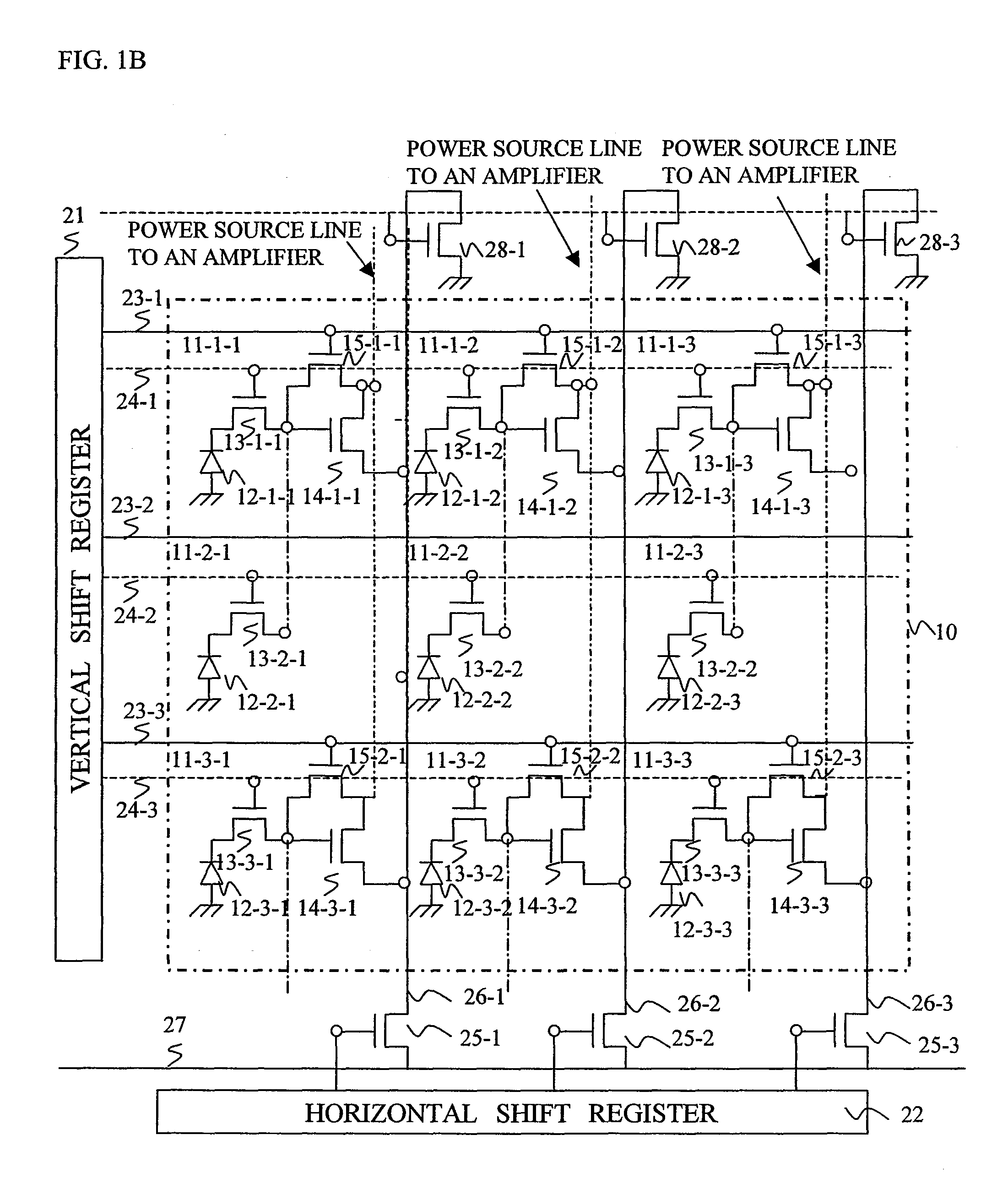

[0076]FIG. 1A is a diagram illustrating one example of a circuit configuration of a solid-state image pickup device according to a first embodiment of the present invention, and FIG. 1B is a diagram illustrating another example of a circuit configuration of a solid-state image pickup device according to the first embodiment of the present invention.

[0077]The solid-state image pickup device according to the first embodiment includes a pixel array region 10 in which a plurality of pixels including photodiodes (12-1-1 to 12-3-1) are disposed in a two-dimensional matrix manner. In FIGS. 1A and 1B, only a part of the plurality of pixels included in the pixel array region 10 is shown.

[0078]FIG. 1A is a diagram illustrating a solid-state image pickup device having a “one pixel to one cell” configuration in which one pixel is included in one cell. In the solid-state image pickup device shown in FIG. 1A, one pixel includes, for example, a photodiode 12-1-1, a transfer transistor 13-1-1, a re...

second embodiment

[0129]FIG. 5A is a schematic diagram illustrating a layout of microlenses 109 in a solid-state image pickup device according to a second embodiment and FIG. 5B is a diagram illustrating an enlarged view of the portion “Q” shown in FIG. 5A. FIG. 6 is a diagram illustrating a cross-sectional view of a pixel disposed in a central portion of a pixel array region.

[0130]Since a circuit configuration of the solid-state image pickup device according to the present embodiment is same as that of the solid-state image pickup device according to the first embodiment shown in FIGS. 1A and 1B, descriptions on the circuit configuration will be omitted here.

[0131]The solid-state image pickup device according to the present embodiment has a structure similar to that of the solid-state image pickup device according to the first embodiment shown in FIG. 1D, except displacement amounts of microlenses 109, color filters 107, and second metal films 106. In other words, as shown in FIGS. 1D and 6, pixels ...

third embodiment

[0165]Hereinafter, a solid-state image pickup device according to a third embodiment of the present invention will be described.

[0166]Since a circuit configuration of the solid-state image pickup device according to the present embodiment is same as that of the solid-state image pickup device according to the first embodiment shown in FIGS. 1A and 1B, descriptions on the circuit configuration will be omitted here.

[0167]A structure of the solid-state image pickup device according to the present embodiment is same as that of the solid-state image pickup device according to the first embodiment shown in FIG. 1D, except displacement amounts of microlenses 109, color filters 107, and second metal films 106. In other words, as shown in FIG. 1D, pixels are formed on a surface of a semiconductor substrate 101, each of which includes a photodiode 110 serving as a photoelectric conversion region, an insulating film 102 formed so as to cover a surface of the photodiode 110, a first metal film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com