Lower-back supporting structure for a bed or a chair

a supporting structure and bed frame technology, applied in the direction of beds, chairs, sofas, etc., can solve the problems of insomnia, lack of sufficient rest, and prior art bed frames all lack a lower-back support function, so as to improve the comfort of the bed frame or chair, ease the pain of the lower back, and increase the lift height of the supporting member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

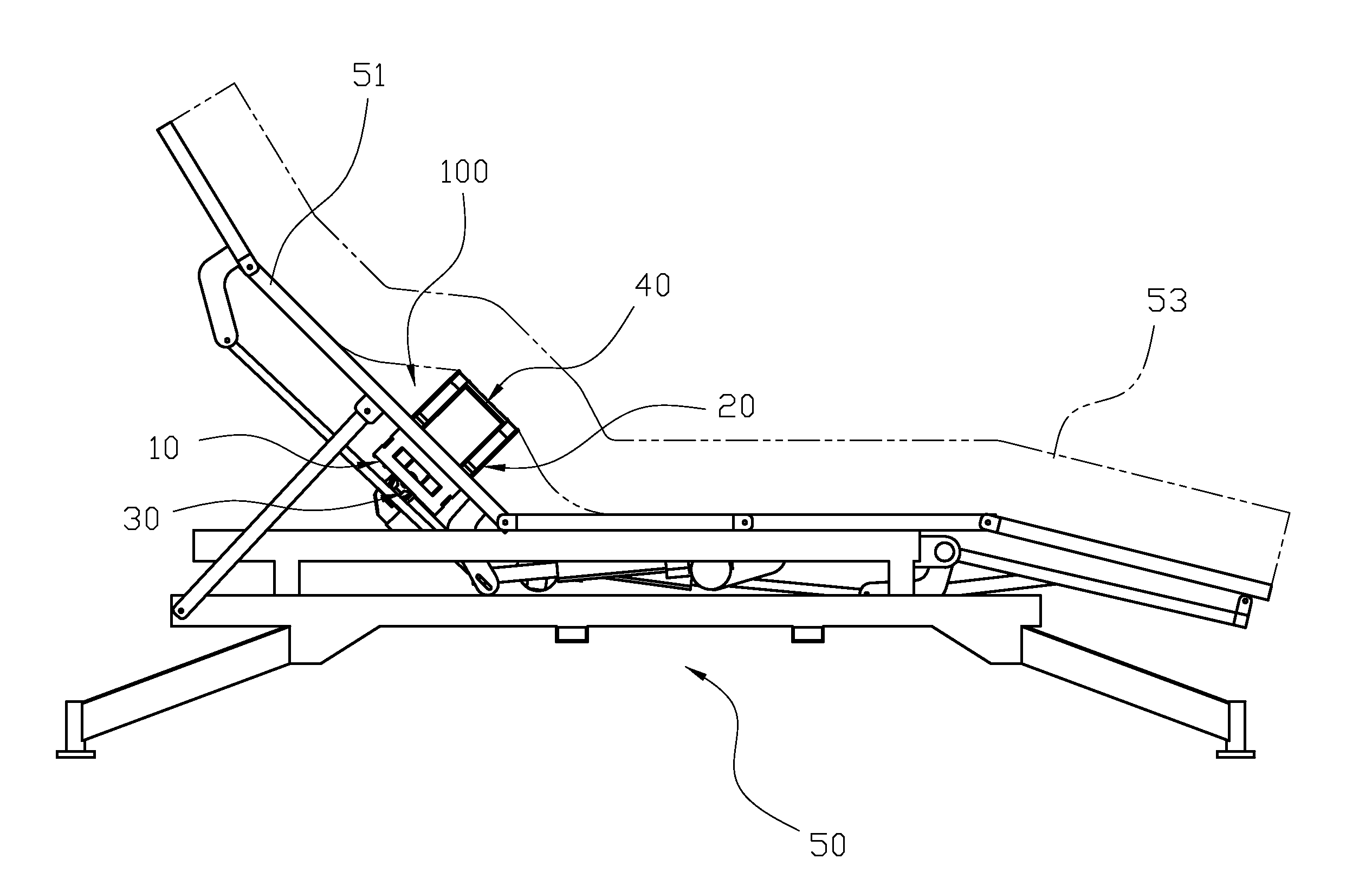

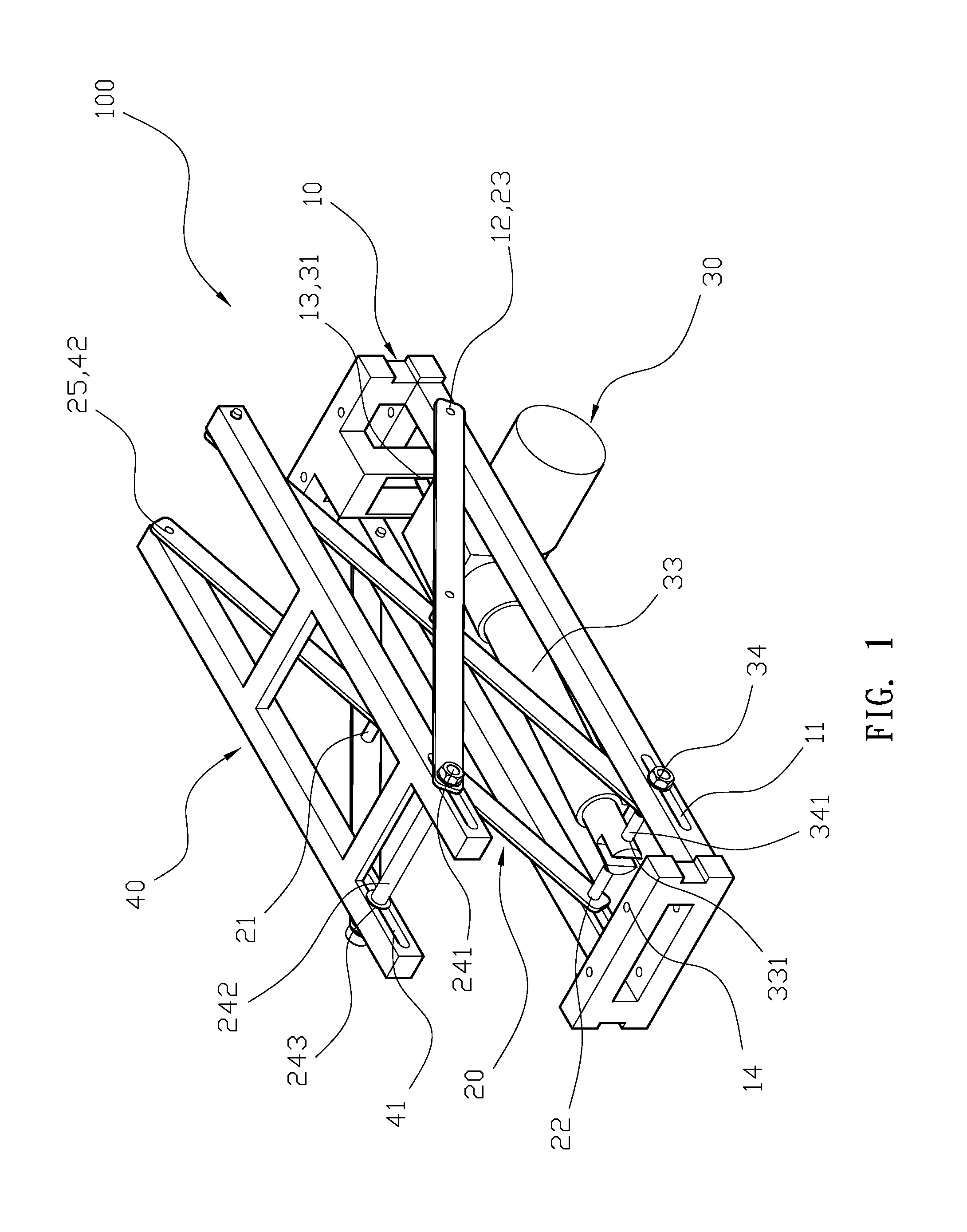

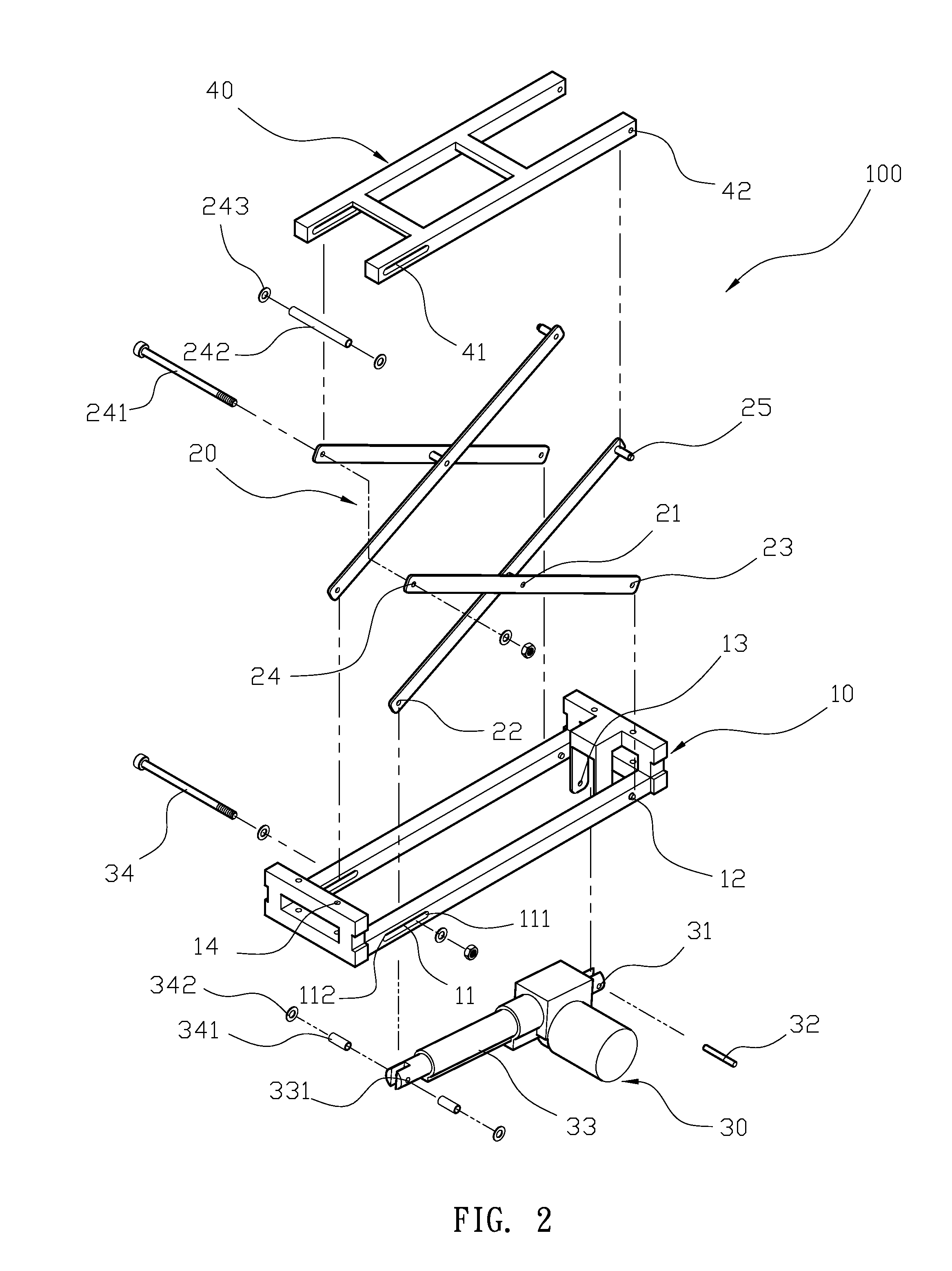

Please refer to FIG. 1 and FIG. 2. An embodiment lower-back supporting structure 100 for a bed or a chair comprises a sliding base 10, two scissor lifts 20, a driver 30 and a supporting member 40. The sliding base 10 is a rectangular frame, and front ends and rear ends of two length-wise sides respectively have a pair of slide slots 11 and a pair of rotating pins 12. Each slide slot 11 is an elongate slot having an inner arcuate region 111 and an outer arcuate region 112 at two respective ends. A securing portion 13 is disposed on a down-extended portion between the two rotating pins 12, and the sliding base 10 includes a plurality of locking apertures 14. The two scissor lifts 20 both are an X-shaped frame having a pivot 21; two bottom ends of each has a first front cotter hole 22 and a rear cotter hole 23, and two top ends of each has a second front cotter hole 24 and rear rotating pin 25. The first front cotter hole 22 of each scissor lift 20 is aligned with the slide slot 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com